25

Bentone BG550/650

General

a

b´

b

a - b

Start-up sequence

b - b´

”idle steps”

up to the self

shut-down of the sequence switch

b ( b´) - a

Post-purge sequence

4.7

Control programme under fault conditions and lockout

indication LFL1....

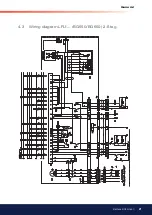

In the event of fault conditions the fuel supply is always interrupted immedia-tely and, simultaneously, the sequence

switch stops and thus the lockout indicator. The symbol appearing above the reading mark indicates the kind of fault:

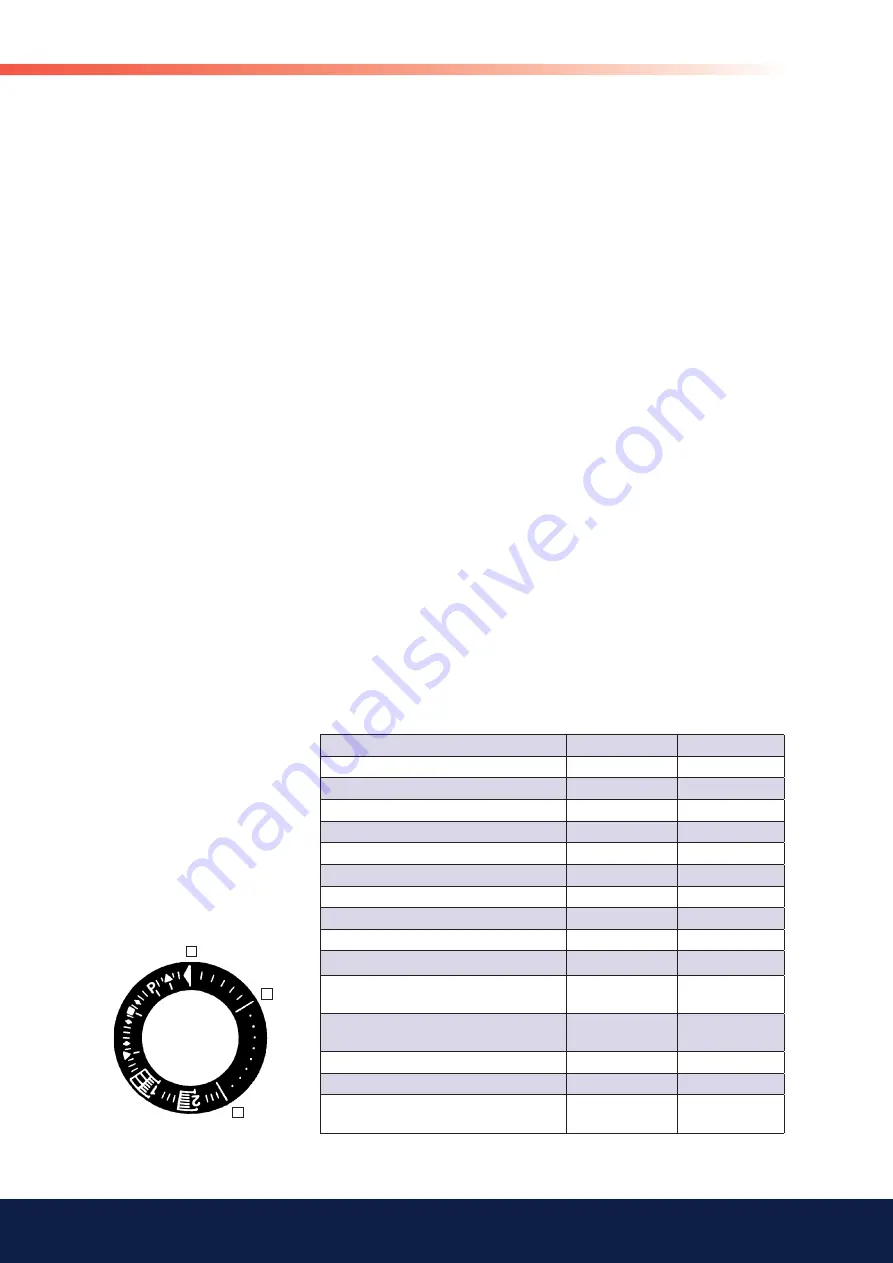

Technical data LFL1.....

1.333

1.635

Pre-purge time with full air volume:

31,5 s

66 s

Pre-iginition time:

6 s

5 s

Safety time:

3 s

2.5 s

Post-ignition time:

3 s

5 s

Reset after lock-out

Immediately

Immediately

Time of re-start:

18 s

18 s

Ambient temperature:

-20°C till +60°C

-20°C till +60°C

Protective standard:

IP 40

IP 40

Supervision of ionization current

Voltage at the detector electrode

operation: 330V

± 10%

operation: 330V

± 10%

test: 380V ±

10%

test: 380V ±

10%

Short circuit current

max. 0,5 mA

max. 0,5 mA

Min. required ionization current

6 µ A

6 µ A

Recommended range of measuring

device

0...50 µ A

0...50 µ A

◄

No start,,

because, e.g., the CLOSE signal has not

been supplied to terminal 8 or a contact has not

been closed between terminals 12 and 4 or 4 and 5.

1

Lockout

because no lame signal has been

received on completion of the 1st safety time.

Any flame signal failure after completion of

the first safety time also causes the control

to go to lockout!

▲

Interruption of the start-up sequence,

because

the OPEN signal has not been supplied to terminal

8 from dam-per motor to switch «max.». Terminals

6, 7and 14 are under tension until the fault has been

remedied.

2

Lockout

because no lame signal has been

received on completion of the 2nd safety time

(lame signal of the main lame with interrupted

pilot burners).

P

Lockout

because the air pressure signal has not

been received at the start of the air pressure check.

Any air pressure failure after this point in time

also causes the control to go to lockout!

▌

Lockout

because the lame signal has been lost

during burner operation or air pressure failure has

occured.

■

Lockout

due to a fault in the lame supervision circuit

◄

Lockout on completion of control

programme sequence

due to extraneous light

(e.g. lame not extinguished, leaking fuel valves)

or due to a faulty lame signal

▼

Interruption of the start-up sequence,

because

the position signal for the low-lame position has not

been supplied to terminal 8 by the damper motor.

Terminals 6, 7 and 14 are under tension until the

fault has been remedied.