46

Bentone BG550/650

General

14. Fault location guide

Gas burner

The basis for a trouble free operation can only be ensured by the correct

combined effect of the three factors:

electricity, gas low and combustion air. Should any of these factors change,

troubles may arise.

t has been proved that many troubles have rather simple causes. Before

calling the serviceman, the following checks should be made:

o facilitate fault location we have drawn up a scheme showing the most

frequent faults in a gas burner installation and the remedies.

1.

Are the gas cocks of the installation open?

2.

Are the fuses in order and the current switched on?

3.

Are the controls (room thermostat, boiler thermostat etc.) correctly

adjusted?

4.

Is the gas pressure to the burner suficient?

5.

Is the gas relay of the burner ready for start and not locked out?

6.

Is the air supply to the burner suficient?

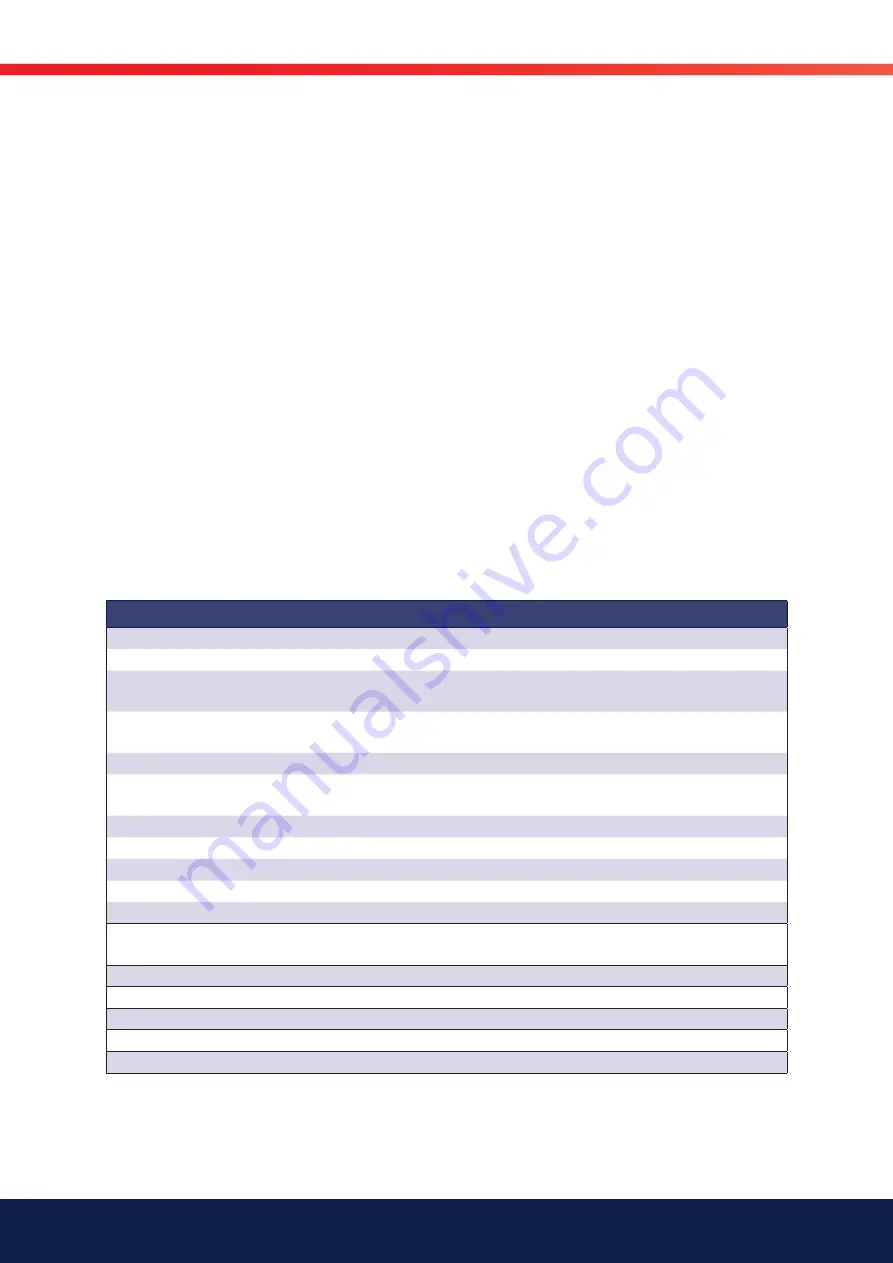

Cause

Remedy

The burner does not start

No gas

Check that all gas cocks are open.

No voltage

Check fuses, thermostats and electrical

connections.

The burner motor fails to start

The thermal protection has locked out.

Motor defective.

The gas relay is defective

Replace

Burner motor is running but no

ignition after the pre-purge time has elapsed

No voltage on the terminals

Check the contact. Replace faulty relay

The ignition electrodes in contact with each other or with earth

Adjust

The porcelain of the electrodes is broken

Replace the electrodes

The cable shoes have bad contact

Improve the contact

The ignition cables are damaged

Replace

The ignition transformer is damaged, no voltage on the secondary

side

Replace the transformer

The ignition cable and the ionisation cable have been transposed.

Change

No flame establishment despite a trouble free start

The gas solenoid valve defective

Replace

The gas solenoid valve does not open despite its obtaining voltage

Replace coil or the whole valve if necessary.

No voltage to the solenoid valve

Check the contact