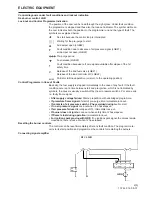

FINAL TEST OF THE INSTALLATION

172 305 17 07-01

–

Make repeated start attempts to

ensure that the adjustments

function.

–

Close the ball valve during

operation to check that the gas

switch switches off at the set

value.

–

Remove the hose for the air

pressure switch to check that

the burner locks out.

–

Check that all protective covers

and measurement nipples are

mounted and fastened.

–

Fill out necessary test reports.

–

Instruct the persons in charge

of the operation on the service

and maintenance of the installa-

tion and what to do should any

troubles occur.

–

Inspection and service must

only be carried out by author-

ized people.

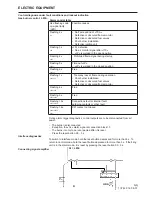

Fault location, functional troubles

Trouble free operation is dependent

on three factors: electricity, gas and air

supply. Should there be any changes

in the ratio between these three factors

there is a risk of break downs. It has

been proved that most break downs

are caused by simple faults. Before

calling the service engineer, the following

should therefore be checked:

–

Is the gas cock open?

–

Are all fuses in order and the

current switched on?

–

Are the thermostats correctly

set?

–

Are pressostats, overheating

protection etc. in operating posi-

tion and not locked-out?

–

Is the gas pressure sufficient?

–

Is the gas burner control in start

position?

–

Has the gas control or the motor

protector locked out? - Reset.

–

Is the circulation pump in opera-

tion?

–

Is there a supply of fresh air to

the installation?

If integral components are of a

different make from what is stated

in this manual, see the enclosed

loose-leaf.

Summary of Contents for STG 146

Page 2: ......

Page 27: ......

Page 28: ...Enertech AB P O Box 309 SE 341 26 Ljungby www bentone se www bentone com...