Panel Mount Instructions

1. Choose mounting location

2. Ensure positive leads are removed from battery banks

3. Use the mounting template (shown on rear page) to mark hole positions

4. Drill four machine screw holes and the 92mm (or 3 5/8”) hole for the switch body.

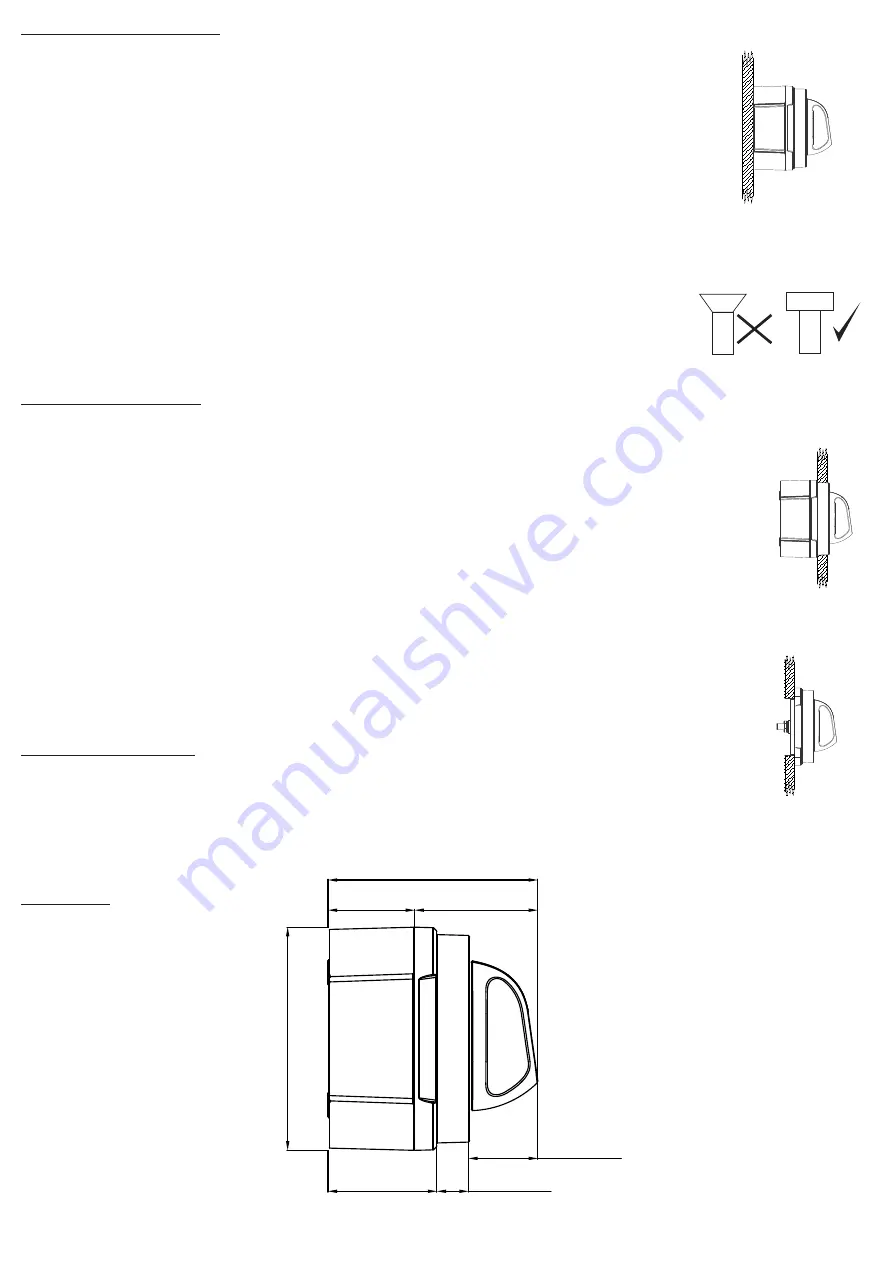

5. Front panel mounting only: either recess for the four clipping features (see template)

or cut/file off these features from the battery switch plate

6. Mount switch to panel using M6 (or ¼”) machine screws

– note: use either pan or cheesehead screws only

7. Connect cables to studs ensuring that batteries and loads are correctly fitted

8. Check that spring washers are fitted beneath nuts

9. Tighten the stud nuts to 13.5 Nm (10 lbf)

10. Tighten the AFD stud nuts to 2 Nm (1.5 lbf)

11. Rear panel mounting only: back plate and side panels can also be clipped to the switch

for cable protection/insulation

12. Ensure cables are secured to ISO/ABYC standards, and that cables are supported so they are not

placing strain on the battery switch studs (see diagram)

13. With switch in “OFF” position connect battery positive leads at battery

14. Check switch operation (as below)

Check switch operation:

a. Loads have no voltage in “OFF” position and AFD contacts are open

b. Loads have voltage in “1 ON” position and the AFD contacts are closed

c. Load share voltage in “2 ON” position and AFD contacts are closed

d. Loads have voltage in 1&2 positions and AFD contact are closed

SURFACE

MOUNT

REAR

PANEL

MOUNT

FRONT

PANEL

MOUNT

SURFACE

MOUNT

REAR

PANEL

MOUNT

FRONT

PANEL

MOUNT

SURFACE

MOUNT

REAR

PANEL

MOUNT

FRONT

PANEL

MOUNT

Surface Mount Instructions

1. Choose mounting location on a flat surface close to the batteries

2. Select panhead (or similar) screws for mounting - use either M5 or 10g imperial

(not included)

3. Knock or drill out plastic skin from screw holes in backplate

4. Select panhead (or similar) machine screws and nuts to secure switch to backplate -

use either M6 x 40mm or 0.25” x 1.5” (not included). Alternatively longer screws

should be used if bolting all the way through the bulkhead/surface

5. Place nuts for machine screws into nut recesses, then screw backplate into position

6. Connect cables to studs ensuring that batteries and loads are correctly fitted

7. Check that spring washers are fitted beneath nuts

8. Tighten the stud nuts to 13.5 Nm (10 lbf)

9. Tighten the AFD stud nuts to 2 Nm (1.5 lbf)

10. Slot the side panel(s) into the backplate as required

11. Clip battery switch and cable assembly into backplate

12. Secure switch in place with machine screws, engaging into nuts under backplate

13. Ensure cables are secured to ISO/ABYC standards, and that cables are supported so

they are not placing unnecessary strain on the battery switch studs (see diagram)

14. With switch in “OFF” position connect battery positive leads at battery

15. Check switch operation (as per below)

TO

RQ

UE

TORQUE

Panhead

Cheesehead

Sockethead

www.bepmarine.com | www.mastervolt.com | www.marinco.com

Mounting Template

Surface Mount Screw Holes

For Backplate

55.0 [2.17]

55.0 [2.17]

76.2 [3.00]

76.2 [3.00]

5.0 [0.20]

6.4 [0.25]

92.0 [3.62]

Use 3

5

8

"

holesaw

47.7 [1.88]

13.9 [0.55]

30.4 [1.20]

97.8 [3.85]

91.9 [3.62]

38.0 [1.50]

53.9 [2.12]

Clipping feature:

• Either remove clipping

features or recess panel

when front panel mounting

Dimensions: