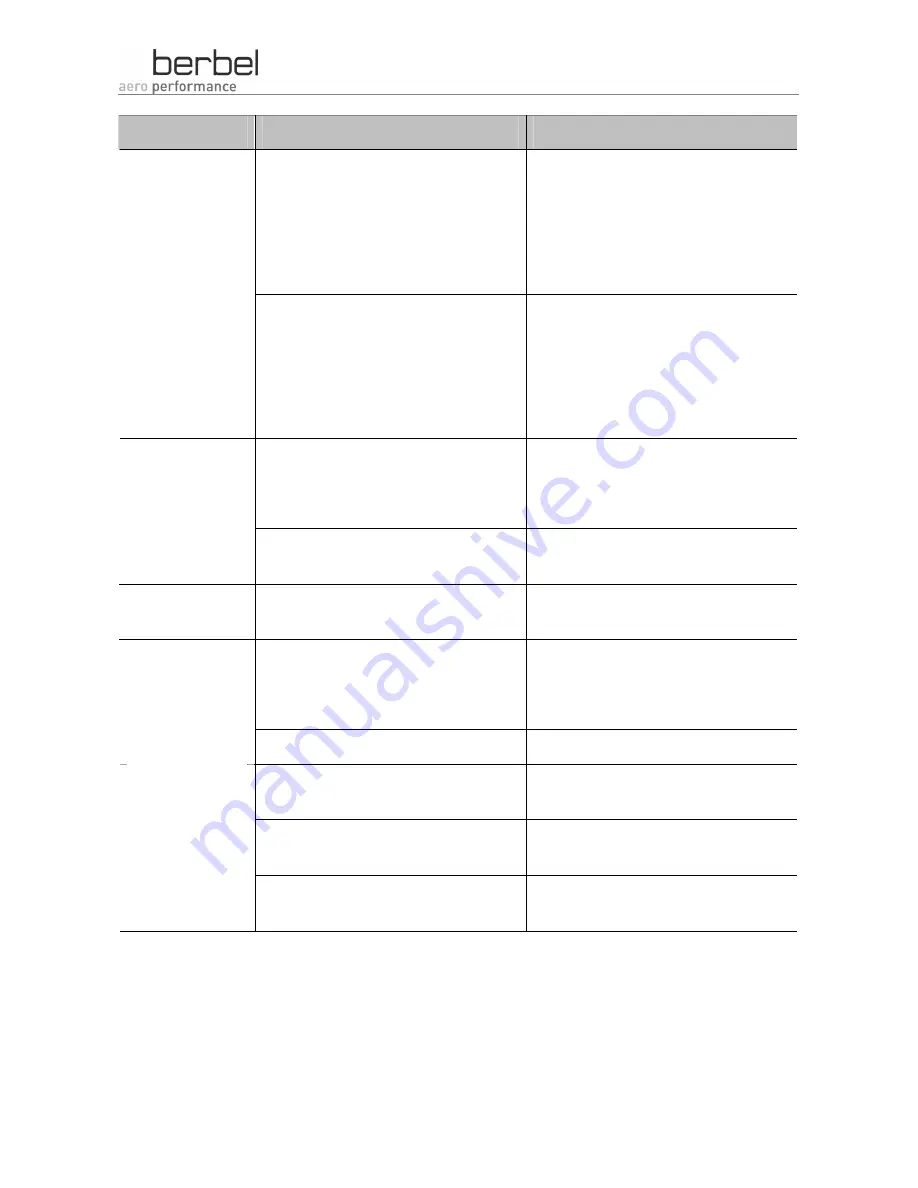

Rectifying malfunctions

31

Malfunction

Possible cause

Remedy

No current supply.

Check whether the fuse has triggered.

If you have a power circuit breaker,

switch the power circuit breaker on.

Contact a specialist electrician in the

case of other fuse types.

Blower and lighting

do not function.

The fuse has triggered or is defective.

Check whether the fuse has triggered.

If you have a power circuit breaker,

switch the power circuit breaker on.

Contact a specialist electrician in the

case of other fuse types.

The extractor hood is not switched on.

Check all four possible output levels.

See Switching on the ventilation function

on page 13.

Blower does not

function.

The extractor hood is connected to a

window switch and the window is closed.

Open the window.

Lighting does not

function.

The light strip is defective.

If the lighting does not function, contact

your specialist berbel dealer.

The recirculating air filter filling is spent.

Replace the recirculating air filter filling.

See Replacing the filter filling (hybrid

and recirculating air filters) on page 23.

Increased noise

development

during operation.

Odour formation during operation.

The hybrid filter filling is spent.

The recirculating air filter has become

clogged.

Replace the filter filling in the

recirculating air filter.

The hybrid filter has become clogged.

Replace the filter filling in the hybrid

filter.

Poor extractor

hood output.

The outgoing air line has not been

connected or routed properly.

Contact your specialist berbel dealer or

the berbel customer service.

¾

If a malfunction cannot be rectified, contact your

specialist berbel dealer or the berbel customer

service.