9

Installation

6005044_0 – 04.12.2019

EN

3.3

Requirements for individual operating modes

Further accessories may be required depending on the

operating mode.

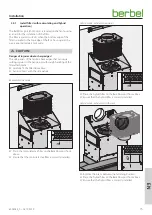

3.3.1

Requirements for recirculated air mode

y

Recirculated air filter at the fan outlet.

y

Cross-section of the ventilation slot in the superstructure

larger than 300 cm

2

.

y

Filter filling freely accessible for changing.

3.3.2

Requirements for extracted air mode

y

Exhaust air ducting at the fan outlet.

D

y

Diameter of the exhaust air ducting at least 150 mm

(corresponds to a surface area of approx. 177 cm

2

).

y

Adequate fresh air supply is assured through the

installation of the necessary accessories.

y

Window contact switch.

y

Wall box.

3.3.3

Requirements for hybrid mode

y

Hybrid filter at the fan outlet.

y

Connection of the exhaust air ducting to the hybrid filter.

D

y

Cross-section of the ventilation slot in the superstructure

larger than 300 cm

2

.

y

Diameter of the exhaust air ducting at least 150 mm

(corresponds to a surface area of approx. 177 cm

2

).

y

Filter filling freely accessible for changing.

y

Adequate fresh air supply is assured through the

installation of the necessary accessories.

y

Window contact switch.

y

Wall box BMK-F 150.

3.4

Requirements for the exhaust air ducting

(only for extracted air mode or hybrid mode)

D

WARNING!

Fire hazard and asphyxiation hazard due to improper

installation!

When using the exhaust air ducting with other devices

or when connecting an active exhaust air channel

(e.g. chimney), gases or smoke can be drawn into the room.

☞

Make sure that the requirements for the exhaust air

ducting are complied with.

y

The exhaust air ducting is used exclusively by this device.

y

The exhaust air ducting is made of non-combustible

material in accordance with DIN 4102 class 1.

y

When using a chimney as the exhaust air duct:

y

The chimney must not be used by other devices.

y

The extracted air must be introduced into the

chimney using a 90° bend pointing upwards.

y

Approval by a master chimney sweep.

y

When routing the exhaust air ducting through the roof or

the outside wall:

y

The cross-section must not be smaller than that of the

fan outlet.

y

Installation of condensed water collector in the

exhaust air ducting in order to prevent water damage

inside the device. The condensed water collector must

be adequately dimensioned.

The cross-section, length, type and course of the exhaust

pipe affect the extraction efficiency. Changing the direction

of the air too severely leads to a loss of performance and to

noise.

To optimise the device performance:

y

Keep the exhaust air ducting as short as possible and

route it directly to the outside.

y

The stipulated cross-section of the exhaust air ducting is

complied with.

D

“3.3 Requirements for individual operating modes”

(page 9).

y

Exclusive use of ducts and bends with smooth inner

surfaces.

In order to avoid turbulence or backpressure in the

transported air - do not use:

y

Spiral hoses.

y

Flexible tubes.

y

Flat deflection pieces.

y

Sharp-edged exhaust air channels.

The exhaust air ducting must be in place before installing

the device.

Summary of Contents for BKH 120 FO

Page 34: ...34 6005044_0 04 12 2019 ...

Page 35: ...35 6005044_0 04 12 2019 ...

Page 36: ...6005044_0 04 12 2019 ...