34

Annex

6004067_a – 01.08.2018

9.2

Accessories

When using accessories, the associated documentation

must be observed.

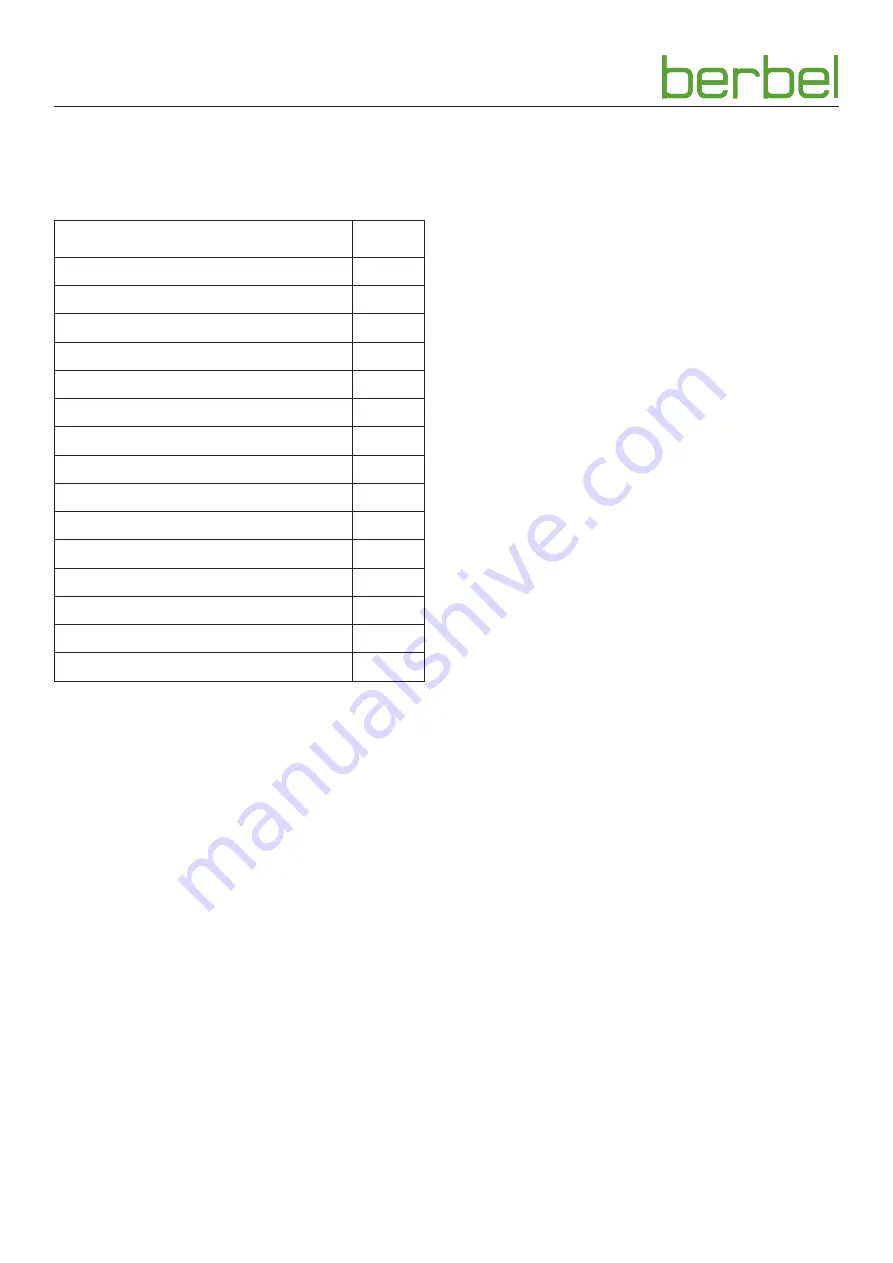

Article

no.

Recirculated air filter BUF 150 +

1003325

Hybrid filter BHF 150 +

1003607

Holding clamp (single)

2000658

Top-up pack berbel Pro Aktiv 150

1000875

Wall box BMK-F 150

1001330

Wall box BMK-Z 150

1001390

Radio window contact switch

1002916

Ventilation grill stainless steel, 2-part

6002271

Conversion to remote control BFB

1004767

Exhaust air set I round 150

1004729

Exhaust air set II flat 150

1004730

Exhaust air set III flat 150 double

1004731

Exhaust air set ECO I round 150

1004732

Exhaust air set ECO II flat 150

1004733

Exhaust air set ECO III flat 150 double

1004734

9.3

Contact

If you have any questions or suggestions, please select from

the following options:

Post:

berbel Ablufttechnik GmbH

Sandkampstraße 100

D-48432 Rheine

Tel:

+49 (0) 5971 80 80 9 - 0

Mon to Thu 08:00 – 17:30 hrs

and Fri 08:00 – 16:30 hrs

Fax:

+49 (0) 5971 80 80 9 - 10

Internet:

www.berbel.de

email:

info@berbel.de

Contact the manufacturer‘s customer support

department

There are several ways for you to contact our customer

service. Please select from the following options:

Tel:

+49 (0) 5971 80 80 9 - 660

Mon to Thu 08:00 – 17:30 hrs

and Fri 08:00 – 16:30 hrs

Fax:

+49 (0) 5971 80 80 9 - 10

email:

service@berbel.de

Summary of Contents for Moveline BTH 100 ML

Page 35: ...35 6004067_a 01 08 2018 EN ...

Page 36: ...6004067_a 01 08 2018 ...