20

Cleaning

6006244_0 – 30.05.2022

D

CAUTION!

Danger of injuries due to device edges!

When removing and replacing the lower section or the cross

flow, fingers may become trapped and crushed.

☞

Move the device parts slowly and carefully.

D

ATTENTION!

Danger of damage due to falling parts!

The lower section and the Capillar Trap can fall down when

being removed and damage the hob, the kitchen furnishings

or other objects.

☞

Hold the parts tightly when removing.

☞

Protect the area below the device (e.g. using thick

cardboard).

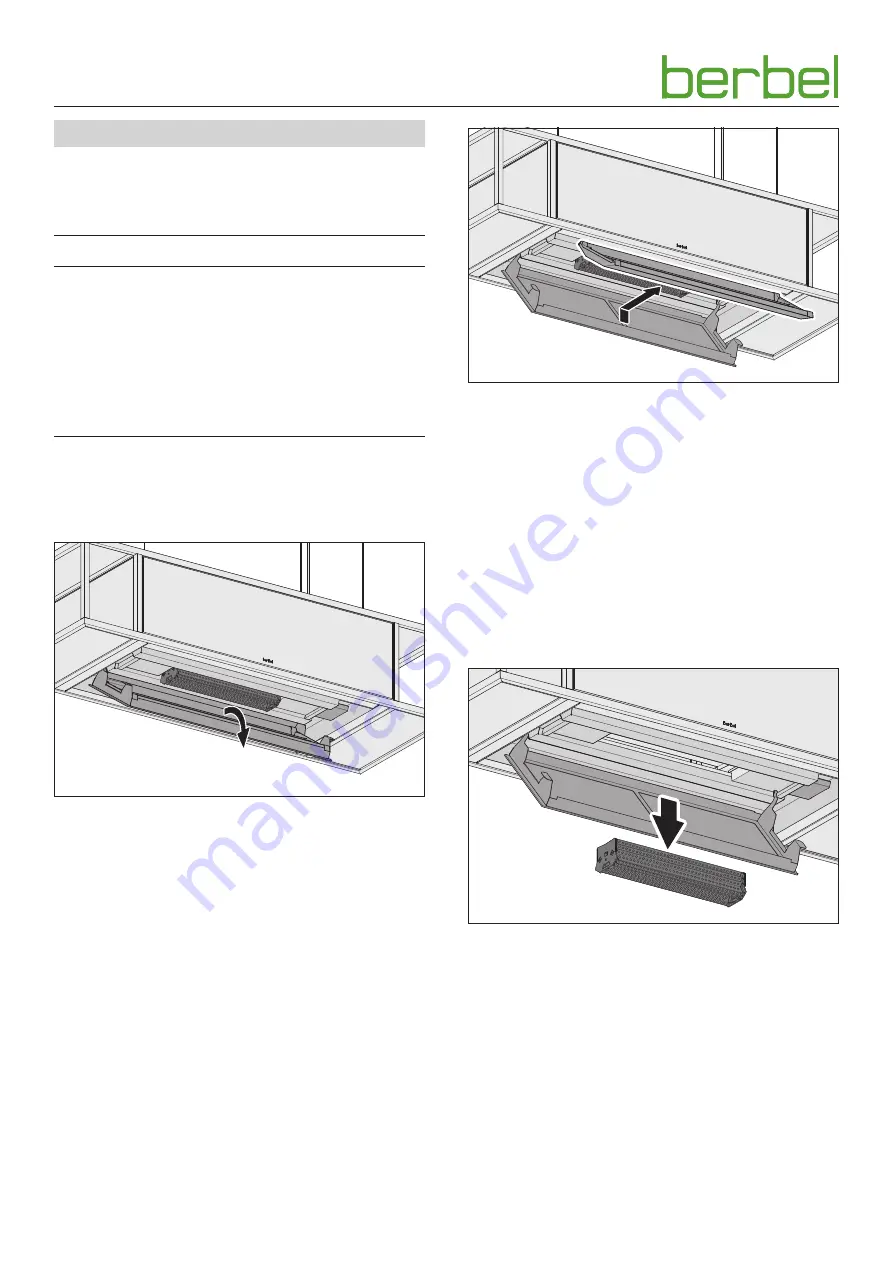

Lower section

The faceplate with the lower section is held in the device by

magnets.

☞

Fold the faceplate down.

☞

Lift up the rear lower section.

☞

Take out the front lower section.

☞

Clean the upper section with a soft, moist cloth.

☞

Clean the lower section with a soft, moist cloth or in a

dishwasher.

☞

Dry the upper and lower sections with a soft cloth.

☞

Insert the front lower section.

☞

Press down the rear lower section.

☞

Fold the faceplate up until the retaining magnets lock in

audibly.

Capillar Trap

The Capillar Trap is inserted into the device above the lower

section and is held by a side rail.

☞

Grasp the Capillar Trap on its sides with both hands.

☞

Pull the Capillar Trap out.

☞

Clean the Capillar Trap e.g. in a dishwasher.

☞

Clean the surfaces and edges on the recess for the

Capillar Trap with a soft, moist cloth.

☞

Make sure that the Capillar Trap is completely dry.

☞

Re-attach the Capillar Trap.

Summary of Contents for Skyline Frame BIH 100 SKF

Page 28: ...6006244_0 30 05 2022 ...