22

Dismounting

6005437_a – 30.05.2022

7.

Dismounting

☞

Move the device into a position where the distance to the

ceiling console is no more than 1150 mm.

D

WARNING!

Risk of death due to electric shock!

Touching live parts can cause an electric shock, burns or

death.

☞

Disconnect all poles of the power supply for the device.

☞

Ensure that the voltage supply is and remains

disconnected while the following work is in progress.

D

WARNING!

Danger of injuries through improper handling!

Taking the device down requires a great deal of physical

exertion due to its size and weight. If the device falls down,

serious injuries are possible.

☞

At least three persons are required to take the device

down.

☞

Ensure stable footing when taking the device down.

☞

Ensure that no other people are in the working area.

D

ATTENTION!

Danger of property damage through improper handling!

Taking the device down requires a great deal of physical

exertion due to its size and weight. If the device falls, the

device, kitchen furnishings and other objects could be

damaged.

☞

Protect the hood body against damage and scratches

(e.g. using a blanket).

☞

Cover the cooled hob.

☞

Keep the installation area clear.

7.1

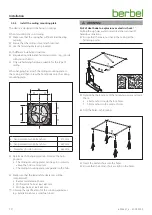

Dismounting the hood body

☞

Set the device down on a suitable surface (e.g. trestle).

☞

Unscrew the lock nuts on the ceiling console’s cover.

☞

Deposit the cover on the body.

☞

Pull out the Wieland plug.

☞

Remove the screws from the cable anchor.

☞

Deposit the mains cable with the Wieland plug on the

body.

If present:

☞

Remove any accessory connection cables.

☞

Have two persons hold the body.

☞

Have a third person unscrew the lock nuts (counter nuts)

for the support cable on the fastening sleeves.

☞

Unscrew the fastening sleeves from the screwed end and

loosen the support cable.

☞

Deposit the support cable on the body.

☞

Secure all moving parts on the hood body.

☞

Set the body down on a clean, solid surface or in the

packaging.

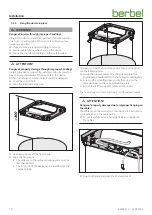

7.2

Dismounting the ceiling mounting plate

☞

Remove the nuts and the washers from the slots in the

ceiling mounting plate.

☞

Unscrew the nuts from the lock holes in the ceiling

mounting plate.

☞

Rotate the ceiling mounting plate.

☞

Remove the ceiling mounting plate.

☞

Set the ceiling mounting plate down on a clean, solid

surface or in the packaging.

☞

Remove the nuts and the washers from the lock holes.

The device is dismounted.

Summary of Contents for Skyline Round BIH 60 SKR

Page 26: ...26 6005437_a 30 05 2022 ...

Page 27: ...27 6005437_a 30 05 2022 ...

Page 28: ...6005437_a 30 05 2022 ...