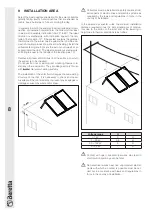

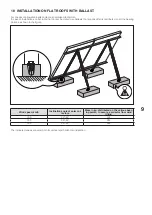

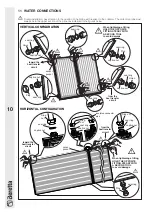

INSTALLATION

13

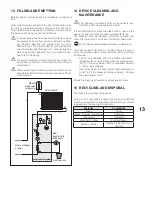

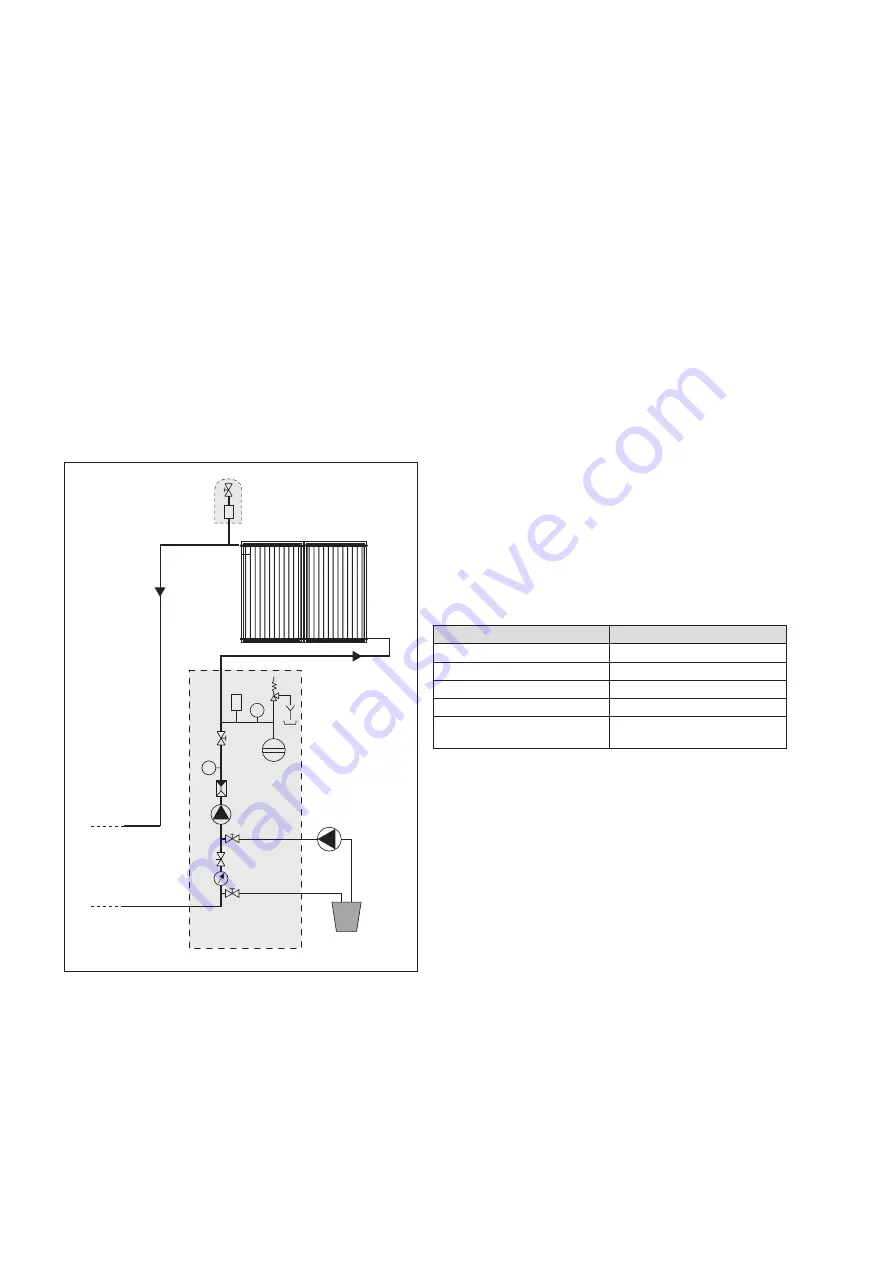

13 FILLING AND EMPTYING

Before system commissioning it is necessary to wash and

fill it.

Solar collectors are exposed to the risk of frost during win-

ter, as they are installed outdoor. Moreover, they can reach

high temperatures in stagnation conditions, consider these

things when choosing the heat transfer fluid.

b

If copper piping has been used and joints have been

hot brazed, flush out the system to remove any braz-

ing residues. Seal test the system after you have

flushed it out. Fill the solar collector with glycol/water

mix immediately after flushing it out, because flushing

water may remain trapped in the circuit (with a conse-

quent risk of freezing).

b

For system washing, filling and emptying, follow the

instructions contained in the manual of the matched

solar station.

b

Filling, emptying and venting must be carried out with

collectors at ambient temperature and protected from

solar radiation.

A

7

°C

Manual

bleed valve

(accessory)

Anti-freez mix

Heat exchanger

of solar

Solar collector

Heat

transfer fluid

filling pump

Water control system

R

M

M

T

14 DEVICE CLEANING AND

MAINTENANCE

b

The following operations must be exclusively per-

formed by Technical Assistance Centre

It is recommended to clean the glass once a year, as the

deposit of dust and leaves reduces system efficiency.

The collector must be cleaned with water or water and

soap. Dry the collector at the end of cleaning operations.

a

Do not use abrasive products, petrol or triethylene.

The heat transfer fluid must be checked every 2 years to

verify the effectiveness of water and glycol mix, including

its pH value.

- Check the antifreeze with the suitable instrument -

refractometer or hydrometer- (nominal value approx.

-30°C): if the limit value of -26°C is exceeded, replace

or top-up the antifreeze.

- Use litmus paper to check the pH (nominal value ap-

prox. 7.5). If the measured value is below 7, change

the heat transfer liquid.

Check the integrity of insulation and expansion joints.

15 RECYCLING AND DISPOSAL

The device is primarily composed of:

At the end of the device's useful life, these components

must be separated and disposed of according to current

regulations in the country of installation.

Material

Component

Glass

Cover

Brass - Copper - Aluminium

Absorber

Rock wool

Insulation

Aluminium - Steel

External frame

Silicone - PA66

Sealing elements of con-

nections