12

EXCLUSIVE

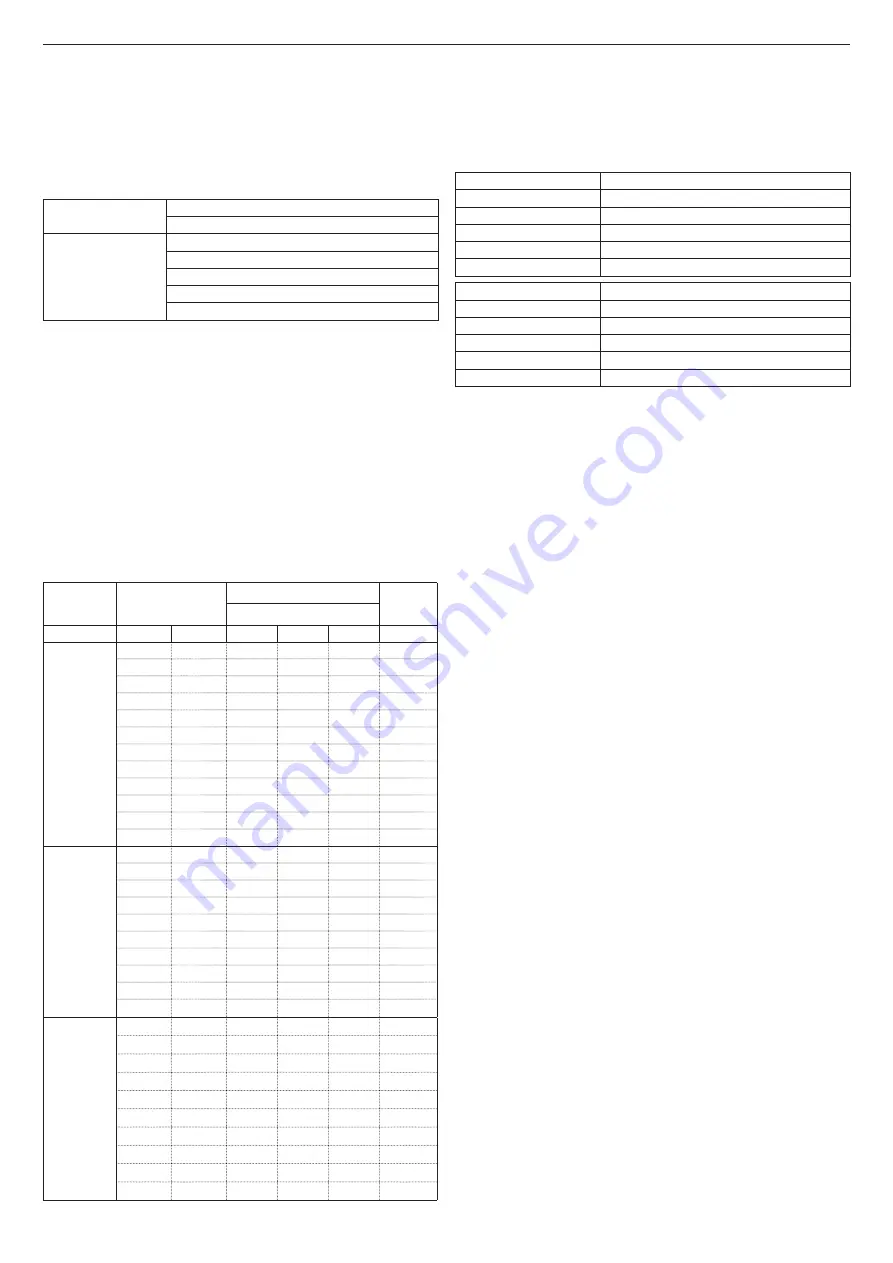

Twin pipes ø 80 with ducting Ø50 - Ø60 - Ø80 (fig. 15a)

Thanks to the boiler characteristics, a flue gas discharge pipe ø 80 can

be connected to the ducting ranges Ø50 - Ø60 - Ø80.

b

For the ducting, you are advised to make a project calculation in

order to respect the relevant standards in force.

The table shows the standard configurations allowed.

Table of standard pipe configurations (*)

Air suction

1 bend 90° ø 80

4,5m pipe ø 80

Flue gas discharge

1 bend 90° ø 80

4,5m pipe ø 80

Reduction from ø 80 to ø50, from ø 80 to ø 60

Stack base bend 90°, ø 50 or ø 60 or ø 80

For ducting pipe lengths see table

(*) Use flue gas system accessories in plastic (PP) for condensing boilers:

Ø50 and Ø80 H1 class and Ø60 P1 class.

The boilers are factory set to:

25C:

5.600 r.p.m. (CH) and 7.900 r.p.m. (DHW) and the maximum length

that can be reached is 6m for the ø 50 pipe, 21m for the ø 60 pipe and 115m

for the ø 80 pipe.

30C:

6.500 r.p.m. (CH) and 7.900 r.p.m. (DHW) and the maximum length

that can be reached is 4m for the ø 50 pipe, 16m for the ø60 pipe and 83m

for the ø 80 pipe.

35C:

6.900 r.p.m. (CH) and 7.800 r.p.m. (DHW) and the maximum length

that can be reached is 1m for the ø 50 pipe, 10m for the ø60 pipe and 54m

for the ø 80 pipe.

Should it be necessary to achieve greater lengths, compensate the pressure

drop with an increase in the r.p.m.of the fan, as shown in the adjustments

table, to ensure the rated heat input.

b

The minimum calibration is not modified.

Adjustments table

Maximum number

of fan rotations

r.p.m.

Ducting pipes

ΔP at

boiler

output

maximum length (m)

CH

DHW

Ø 50

Ø 60

Ø 80

Pa

25C

5.600

7.900

6

21

115

180

5.600

8.000

8 (*)

25 (*)

139 (*)

210

5.700

8.100

10 (*)

32 (*)

175 (*)

255

5.700

8.200

12 (*)

35 (*)

195 (*)

280

5.800

8.300

14 (*)

42 (*)

231 (*)

325

5.900

8.400

17 (*)

48 (*)

263 (*)

365

6.000

8.500

19 (*)

53 (*)

291 (*)

400

6.100

8.600

22 (*)

60 (*)

331 (*)

450

6.200

8.700

24 (*)

66 (*)

363 (*)

490

6.200

8.800

26 (*)

71 (*)

389 (*)

523

6.300

8.900

28 (*)

76 (*)

420 (*)

562

6.400

9.000

31 (*)

82 (*)

452 (*)

601

30C

6.500

7.900

4

16

83

190

6.600

8.000

5 (*)

19 (*)

103 (*)

225

6.700

8.100

7 (*)

24 (*)

128 (*)

270

6.800

8.200

9 (*)

28 (*)

151 (*)

310

6.900

8.300

11 (*)

33 (*)

174 (*)

350

7.000

8.400

13 (*)

37 (*)

196 (*)

390

7.100

8.500

14 (*)

40 (*)

213 (*)

420

7.200

8.600

16 (*)

44 (*)

236 (*)

460

7.300

8.700

17 (*)

48 (*)

256 (*)

495

7.400

8.800

19 (*)

53 (*)

281 (*)

540

35C

6.900

7.800

1

10

54

161

7.000

7.900

2

12

68

190

7.100

8.000

3 (*)

16 (*)

86 (*)

225

7.200

8.100

4 (*)

18 (*)

101 (*)

255

7.300

8.200

6 (*)

23 (*)

124 (*)

300

7.400

8.300

7 (*)

25 (*)

140 (*)

330

7.500

8.400

10 (*)

32 (*)

175 (*)

400

7.600

8.500

11 (*)

35 (*)

191 (*)

430

7.700

8.600

13 (*)

39 (*)

216 (*)

480

7.800

8.700

14 (*)

42 (*)

231 (*)

510

(*) Maximum installable length ONLY with exhaust pipes in H1 class.

Configurations Ø50 or Ø60 or Ø80 show test data verified in the laboratory.

In the case of installations that differ from those indicated in the “standard

configuration” and “adjustments” tables, refer to the equivalent linear

lengths below.

b

In any case, the maximum lengths declared in the booklet are

guaranteed, and it is essential not to exceed them.

COMPONENT Ø 50

Linear equivalent in metres Ø80 (m)

Bend 45° Ø 50

12,3

Bend 90° Ø 50

19,6

Extension 0.5m Ø 50

6,1

Extension 1.0m Ø 50

13,5

Extension 2.0m Ø 50

29,5

COMPONENT Ø 60

Linear equivalent in metres Ø80 (m)

Bend 45° Ø 60

5

Bend 90° Ø 60

8

Extension 0.5m Ø 60

2,5

Extension 1.0m Ø 60

5,5

Extension 2.0m Ø 60

12

3.9 Filling the heating system (fig. 16)

Note:

even if the boiler is fitted with a semi-automatic filling device, the

first filling operation must be carried out by turning the filler tap (

B

) with the

boiler off.

Once the hydraulic connections have been carried out, fill the heating

system. This operation must be carried out when the system is cold,carrying

out the following operations:

- open the caps of the lower (

A

) automatic air vent valve by two or three

turns; to allow a continuous venting of the air, leave the plug of the valve

A

open

- make sure the cold water inlet tap is open

- open the filling tap (

B

) until the pressure indicated by the water pressure

gauge is between 1 and 1.5 bar

- re-close the filling tap.

b

The venting of the boiler takes place automatically via the two

automatic vent valve

A

positioned on the circulator.

3.10 Draining the heating system (fig. 16)

Before starting emptying, switch off the electricity supply by turning off the

main switch of the system.

- Close the heating system’s valves.

- Connect a hose to the system drain valve (

C

).

- Manually loosen the system drain valve (

C

).

3.11 Emptying the domestic hot water system

Whenever there is risk of frost, the domestic hot water system must be

emptied in the following way:

- turn off the main water supply tap

- turn on all the hot and cold water taps

- drain the lowest points.

3.12 Circulator settings

Circulator residual discharge head

The boilers is equipped with an already hydraulically and electrically

connected circulator, whose useful available performance is indicated in

the graphs at page 42.

The circulator comes set from the factory with a 6 metre discharge head curve.

The boiler is equipped with an anti-blocking system which starts up an

operation cycle after every 24 hours in standby with the mode selector in

any position.

b

The “antiblocking” function is active only if the boiler is electrically

powered.

a

Operating the circulator without water is strictly forbidden.

If you need to use a different curve you can select the desired level on the

circulator.

Below the main characteristics and the ways to set up their desired operation

are listed.

3.12.1 User interface

The user interface is made up of a button (

A

), a two-coloured red / green

LED (

B

) and four yellow LEDs (

C

) arranged in a row.

Summary of Contents for EXCLUSIVE C

Page 101: ... ...