42

EXCLUSIVE

For fault E041

If the pressure drops below the safety threshold of 0.3 bar the boiler displays

the fault code “E041 - WATER TRANSDUCER PRESS OK TO FILL THE

SYSTEM” for a transitional time of 10 min during which it is possible to

start the semi-automatic loading procedure, pressing the

“ok”

key to fill

the system (the procedure can only be started in SUMMER or WINTER).

E041

WATER TRANSDUCER

PRESS OK TO LOAD THE PLANT

PRESS OK FOR AUTO FILL

WATER TRANSDUCER

During the loading phase the scrolling message “SEMI-AUTOMATIC

FILLING IN PROGRESS” is displayed at the foot of the screen, while the

pressure highlighted on the display should start to rise.

When the loading is finished the scrolling message “SEMI-AUTOMATIC

FILLING FINISHED” is displayed at the foot of the page.

When the transitional time has finished, if the fault persists the fault code

E040 is displayed.

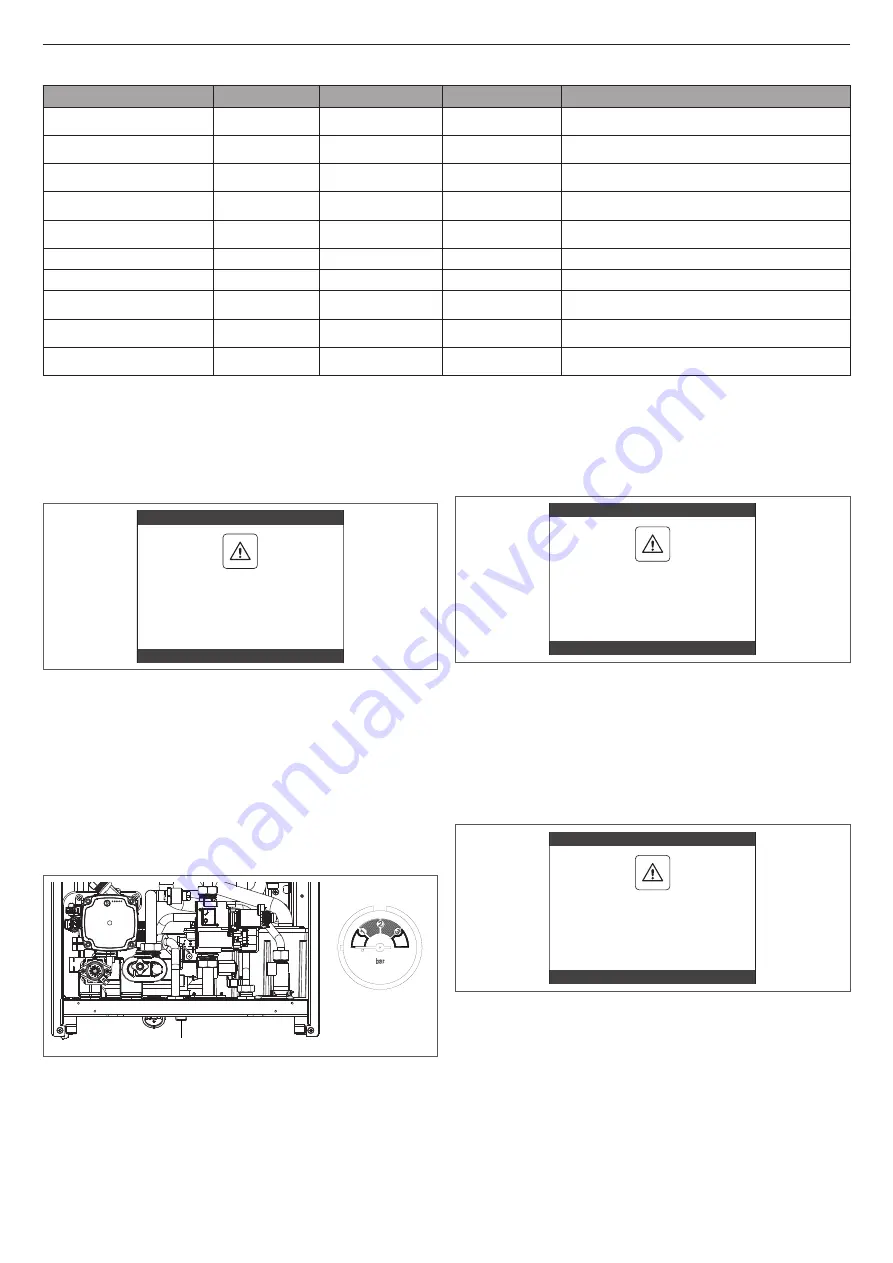

When the boiler has fault E040 manual loading should be carried out using

the filler tap (

A

) until the pressure is between 1 and 1.5 bar.

b

If the pressure drops frequently, contact the Technical Assistance

Centre.

A

For fault E091

The boiler has an auto-diagnostic system which, based on the total number

of hours in certain operating conditions, can signal the need to clean the

primary heat exchanger.

The intervention of the Technical Assistance Centre is necessary.

14.1 Reset function

In order to reset the boiler’s operation in the event of a fault, it is necessary

to access the fault description screen. If the lockout is of a non-volatile type

that requires a reset procedure, this will be indicated on the screen, and can

be carried out by pressing the

“ok”

button on the REC10.

E020

LIMIT THERMOSTAT

PRESS OK RESET

PRESS OK TO RESET

LIMIT THERMOSTAT

At this point, if the correct operating conditions have been restored, the

boiler will restart automatically.

If the attempts to reset the fault do not restore the boiler’s functionality,

please contact your local Customer Support Service.

Up to a maximum of 3 reset attempts can be made using the REC10, after

which the machine must be disconnected from the power supply to reset

the number of attempts available.

b

Request the intervention of the Technical Assistance Centre.

E020

LIMIT THERMOSTAT

REC10 ATTEMPTS EXHAUSTED

RESET ATTEMPTS EXHAUSTED

LIMIT THERMOSTAT

Warning lights

BOILER STATUS

RED LED

GREEN LED

RED and GREEN

NOTES

Power-on

flashing

0.5 sec. on/0.5 sec. off The red and green LEDs come on at the same time

Vent cycle

flashing

0.5 sec. on/1 sec. off

flashing

0.5 sec. on/1 sec. off

The red and green LEDs come sequentially one at a time

OFF status

flashing

0.3 sec. on/0.5 sec. off

No heat request (stby)

flashing

0.3 sec. on/0.5 sec. off

Transitional ignition/

overtemperature

flashing

0.3 sec. on/0.5 sec. off

Presence of flame

ON

Chimney sweep

ON

Only if the flame is present

Screed heater

flashing

1 sec. on/1 sec. off

flashing

1 sec. on/1 sec. off

The red and green LEDs come on alternately

Semi-automatic filling in progress

flashing

0.5 sec. on/1 sec. off

flashing

0.5 sec. on/1 sec. off

The red and green LEDs come sequentially one at a time

Semi-automatic filling finished

ON

The red and green LEDs are on and fixed and at the same

time for about 4 sec

Summary of Contents for EXCLUSIVE C

Page 101: ... ...