20

EXCLUSIVE

4.1 Access to the technical parameters

Through the REC10 it is possible to access, using the TECHNICAL menu,

a series of parameters that can be programmed to allow you to personalise

the operation of the boiler:

- select MENU on the initial page of the REC10 and press the key

18/05/2013

12:17

INFO

SET

30

°C

.3

MENU

FRI

STATE

PLANT

HOT WATER TEMPERATURE

1.3 bar

MENU

STATE

SET

INFO

PLANT

HOT WATER TEMPERATURE

FRI

- keep the keys

and

pressed at the same time to enter the

password menu (about 5 sec)

18/11/2013

12:17

FRI

SETTINGS

MENU

SELECT OPTION

MENU

SETTINGS

SELECT OPTION

FRI

- using the keys

and

select the value of the password to

access the INSTALLER or SERVICE authorisation level, depending on

the level of the tree menu, then press the key

00

INSERT PASSWORD

INSERT PASSWORD

- select TECHNICAL with the keys

and

, confirming the

selection with the key

SETTINGS

TECHNICAL

SELECT OPTION

MENU

SELECT OPTION

SETTINGS

TECHNICAL

MENU

- access the desired menu and change/view the parameter concerned

(see the menu tree on page 8).

It is possible to return to the start page at any time by keeping the key

“back”

pressed for at least 2 seconds.

5 COMMISSIONING

5.1 Preliminary checks

First ignition is carried out by competent personnel from an authorised

Technical Assistance Service Beretta.

Before starting up the boiler, check:

- that the data of the supply networks (electricity, water, gas) correspond

to the label data

- that the extraction pipes of the flue gases and the air suction pipes are

working correctly

- that conditions for regular maintenance are guaranteed if the boiler is

placed inside or between items of furniture

- the seal of the fuel adduction system

- that the fuel flow rate corresponds to values required by the boiler

- that the fuel supply system is sized to provide the correct flow rate to

the boiler, and that it has all the safety and control devices required by

current regulations

- that the circulator rotates freely because, especially after long periods of

inactivity, deposits and/or debris can prevent free rotation.

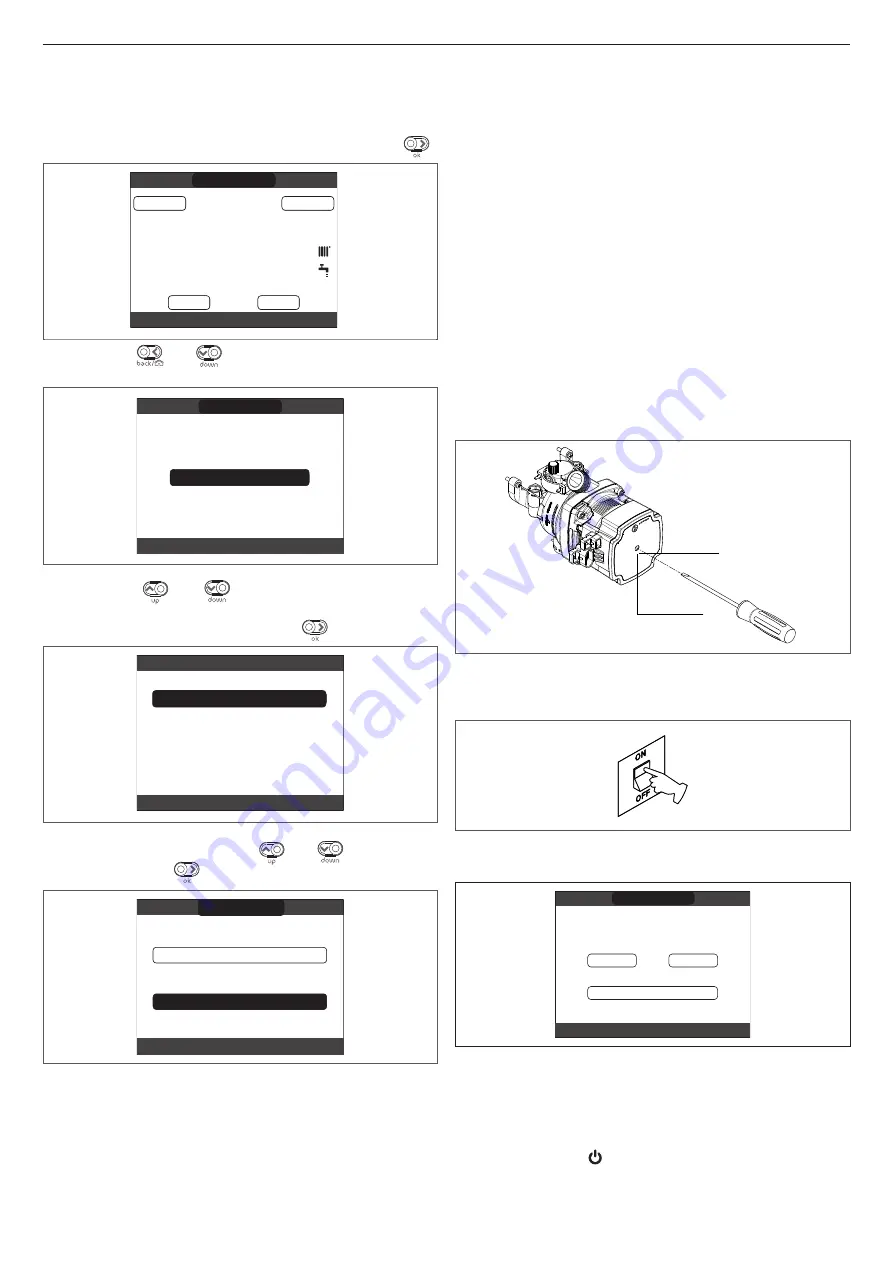

Eventual releasing of the circulator shaft

- Insert a screwdriver in the hole (

1

) of the circulator.

- Press (

a

) and turn the n° 2 Phillips screwdriver (

b

) until the release of

the crankshaft.

Perform this operation with extreme caution to avoid damaging the

components.

a

b

1

5.2 Programming the boiler

- Position the system’s master switch to the “on” position.

- If necessary set the TIME and DATE setting the HOURS, MINUTES,

DAY, MONTH and YEAR with the keys

“up”

and

“down”

, confirming

the selection.

-

12

17

:

ENTER TIME AND DATE

TIME & DATE

USE THE ARROWS TO MODIFY

18 / 11 / 2013

ENTER TIME AND DATE

TIME & DATE

USE THE ARROWS TO MODIFY

Note: it is possible to change the TIME and DATE settings, as well as

LANGUAGE and the duration of the back-lighting, also later by entering

the MENU from the main screen and then selecting SETTINGS.

b

Each time that the boiler is powered an automatic venting cycle is

carried out lasting 2 min. To interrupt the vent cycle, carry out the

procedure explained in the section

- Set the boiler to OFF from REC10 selecting the STATE menu and

then BOILER.

Summary of Contents for EXCLUSIVE C

Page 101: ... ...