8

20129019 - Rev

. 3 (01/18)

END USER

12 RECYCLING AND DISPOSAL

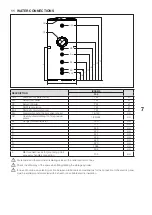

The device is primarily composed of:

Material

Component

steel

structural work

PU (polyurethane)

insulation

PE (polyethylene)

water connection washers

ABS (acrylonitrile-butadiene-styrene)

lining and covers

At the end of the device's useful life, these components must be separated and disposed of according to current regu-

lations in the country of installation.

END USER INSTRUCTIONS

Refer to the GENERAL SAFETY INFORMATION and PRECAUTIONS section for safety-related information

13 START-UP

The heater commissioning must be performed by Techni-

cal Assistance Centre personnel.

Under certain circumstances, such as after long periods of

disuse, the user may need to re-start it without involving the

Technical Assistance Centre. Before doing so, perform the

following checks and operations.

- Check that the supply cocks in the domestic water

circuit are all open

- Switch the electricity supply ON at the mains power

switch and at control panel switch (if fitted).

14 TEMPORARY SHUTDOWN

To reduce to the environmental impact and save energy,

in case of brief absences, week-ends, short trips, etc., and

with external temperatures above 0°C, set the heater tem-

perature control, where available, to the minimum value.

b

If the temperature to which the heater is exposed can

fall below 0°C (frost hazard), perform the operations

described in paragraph "Preparing for extended pe-

15 PREPARING FOR EXTENDED

PERIODS OF DISUSE

If the storage cylinder is not going to be used for an ex-

tended period of time, ask the manufacturer’s Technical

Assistance Centre to make the system safe.

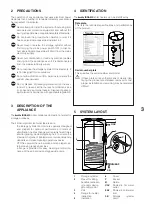

16 EXTERNAL MAINTENANCE

Clean the outside of the storage cylinder with a soft cloth

damped in soapy water.

a

Do not use abrasive products, petrol or triethylene.

End user

Via Risorgimento, 23 A

23900 - Lecco (LC), Italy

www.berettaboilers.com

The manufacturer strives to continuously improve all products. Appearance, dimensions, technical

specifications, standard equipment and accessories are therefore liable to modification without notice.