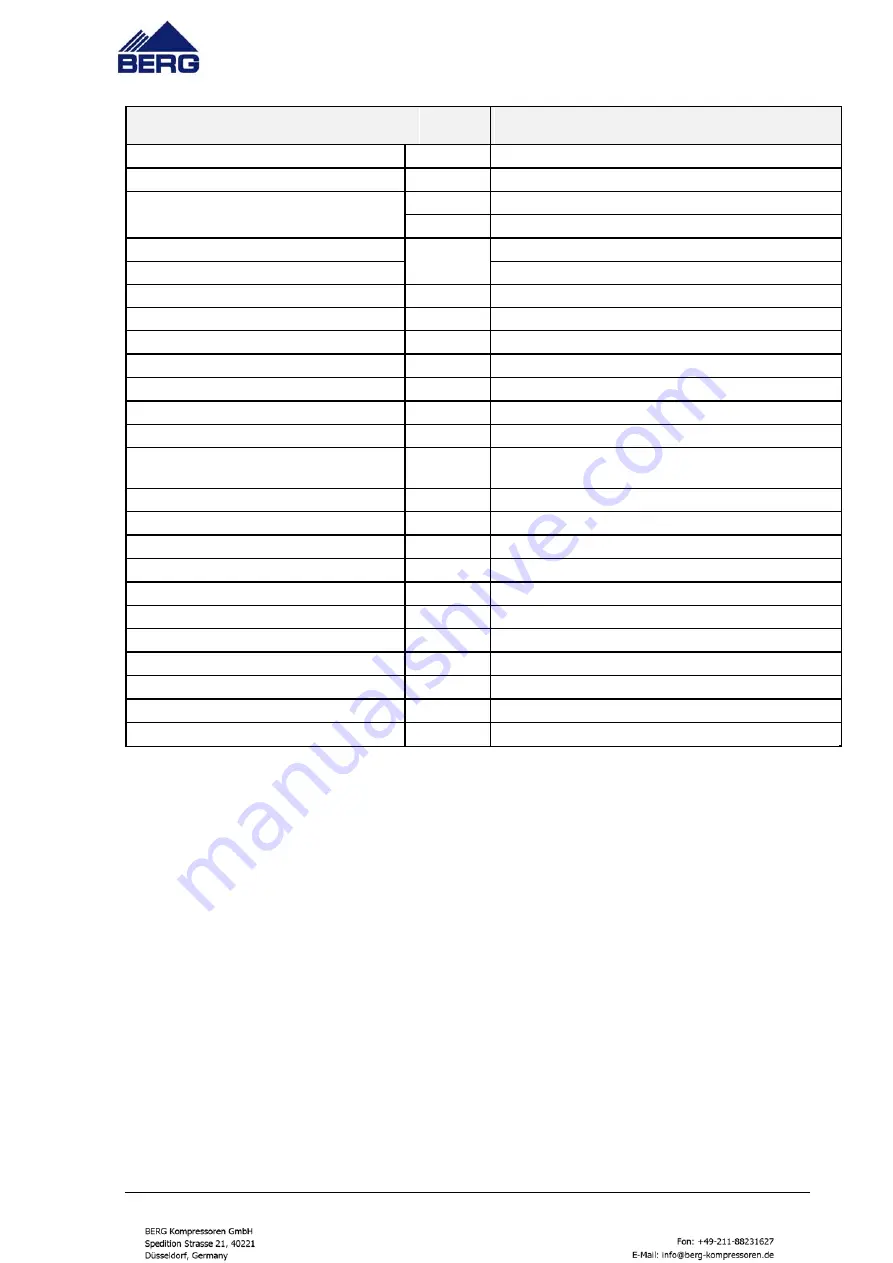

5. Technical data

KOMPBERG BKB22 TWIN

Overpressure

MPa 4,0

Suction overpressure

MPa 1,0

Efficiency *)

m

3

/h

600

m

3

/min

10

Weight of compressor

kg

1200

Weight of electrical box

8

Dimensions of compressor (LxWxH)

mm

1607x851x1955

Dimensions of electrical box (LxWxH)

mm

278x500x1600

Suction air connection

G2

Compressed air connetion

G1¼

Inlet height dimension

mm

747

Outlet height dimension

mm

587

Ambient temperature

0

C

from +5 to +40

Air temperature on the outlet

0

C

approx.20 above ambient temperature

Noise level L

**

)

dB(A)

82

Compressor

V3.7.C

Number of cylinders

2

Cylinders diameters

mm 72

Piston stroke

mm 85

Rotational Speed

rpm

900

Volume of oil

dm

3

3,6

Using oil up

g/h

≤

8,5

Motor power

kW

2 x 22

Motor rotational speed

rpm 3000

Feed voltage

400V / 50Hz / 3Ph

*) - capacity measured acc. to ISO 1217, 1999

**) - momentary value of acoustic pressure corrected by C characteristic does not exceed 130 dB;

- equivalent acoustic pressure level corrected by A characteristic does not exceed 85 dB(A).

6. Operating description

6.1. Air circuit

The air supplied to the head passes through the head chamber and suction valve to the

cylinder. Once compressed in the cylinder, the air is forced through the pressure valve to

the end cooler.

After being cooled, the air passes through filters (option) and is supplied to the air tank.

As water condenses during the cooling and compressing process, the KOMPBERG

BKB22 TWIN booster cooler is provided with a valve for draining the condensate.

6.2. Lubrication system

Oil sucked by the gear pump is initially purified in the suction filter. Oil is forced through

the fine filter to the hole in the crankshaft, and further on through gaps in the crank pin to

the crank bearing bushings and pins.