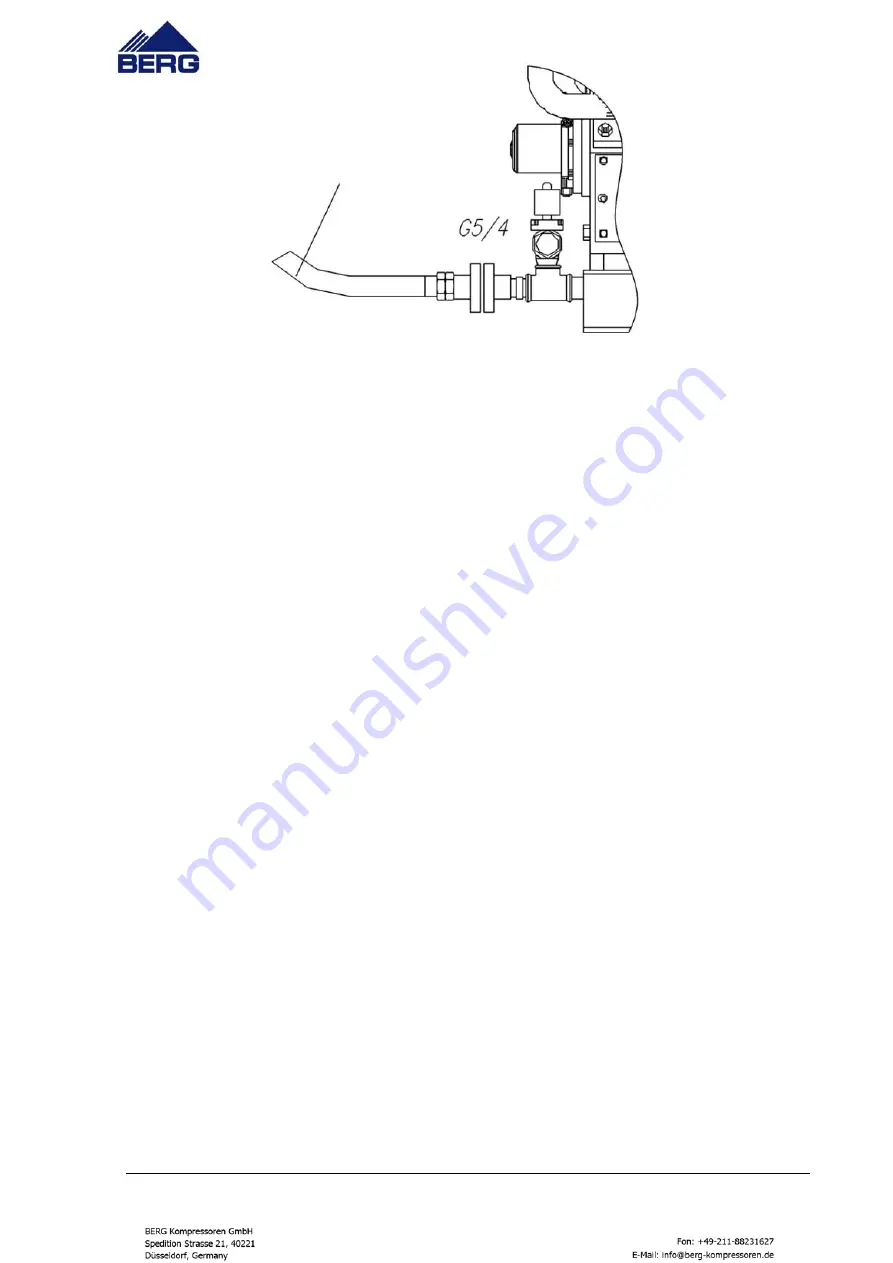

Compressed air connection for KOMPBERG BKB22 TWIN

3.4. Compressed air treatment

Depending on the desired quality of compressed air, additional equipment for air

purification such as dehydrators, filters or drier should be installed downstream the

compressor.

Our specialists will select appropriate equipment free of charge.

4. Technical description

4.1. Applications

The KOMPBERG series booster compressors are intended for boosting air pressure from

1.0-1.3 MPa (KOMPBERG BKB22 TWIN) on the suction side, to 2.5-4.0 MPa on the

pressure side. The booster is provided with an oil filter and end cooler.

4.2. Main components

The booster compressor comprises an oil piston compressor with “V” cylinder

arrangement at 90° angle. The compressor is driven by an electric motor with a belt

transmission. A common frame supports the compressor, motor and air end cooler with

fans and filters.

4.3. The compressor

It is a single-stage compressor with two cylinders, one-side action, with “V” cylinder

arrangement at 90° angle.

The compressor has a tunelled iron cast crankcase. The crankcase bottom serves also

as an oil sump with the oil suction filter built in. The oil filter is installed in the oil pump.

Two cylinders with valves are mounted to the crankcase. The valves are held in place in

their seats in the head with adjustment bolts through special thrust sleeves. The cylinders

have special ribs to ensure efficient heat removal.

The crankshaft forged of increased impact-resistant steel is supported on two rolling

bearings. On one side, the crankshaft is provided with a cone end for pulley mounting,

whereas the other end drives the oil gear pump.

On a skin-hardened crank pin of the shaft, two connecting rods with thin-wall double-split

bearing bushings are mounted.

There are no separate heads in the compressor, as the cylinder and head is a one-

component iron cast. Both cylinders are linked with a common suction collector, at the

inlet side, and with the air end cooler, at the outlet side.

Pneumatic

hose