4.4. Electric motor

The booster compressor is driven by a squirrel-cage, AC electric motor. The motor is

designed for an intermittent run, for maximum 20 starts per hour. The compressor is

driven by the motor via a belt transmission.

4.5. End cooler

The cooler in the KOMPBERG boosters is made of vertical ribbed steel tubes connected

with horizontal collectors at the ends. The cooler has welded construction. In the upper

cooler collectors, valves for draining condensate and a relief solenoid valve are provided.

Air circulation in both solutions is forced by a fan driven by an electric motor.

4.6. Booster compressor frame

The KOMPBERG BKB22 TWIN booster frame, on which the motor and compressor are

supported, is made of plate and seated on four shock absorbers.

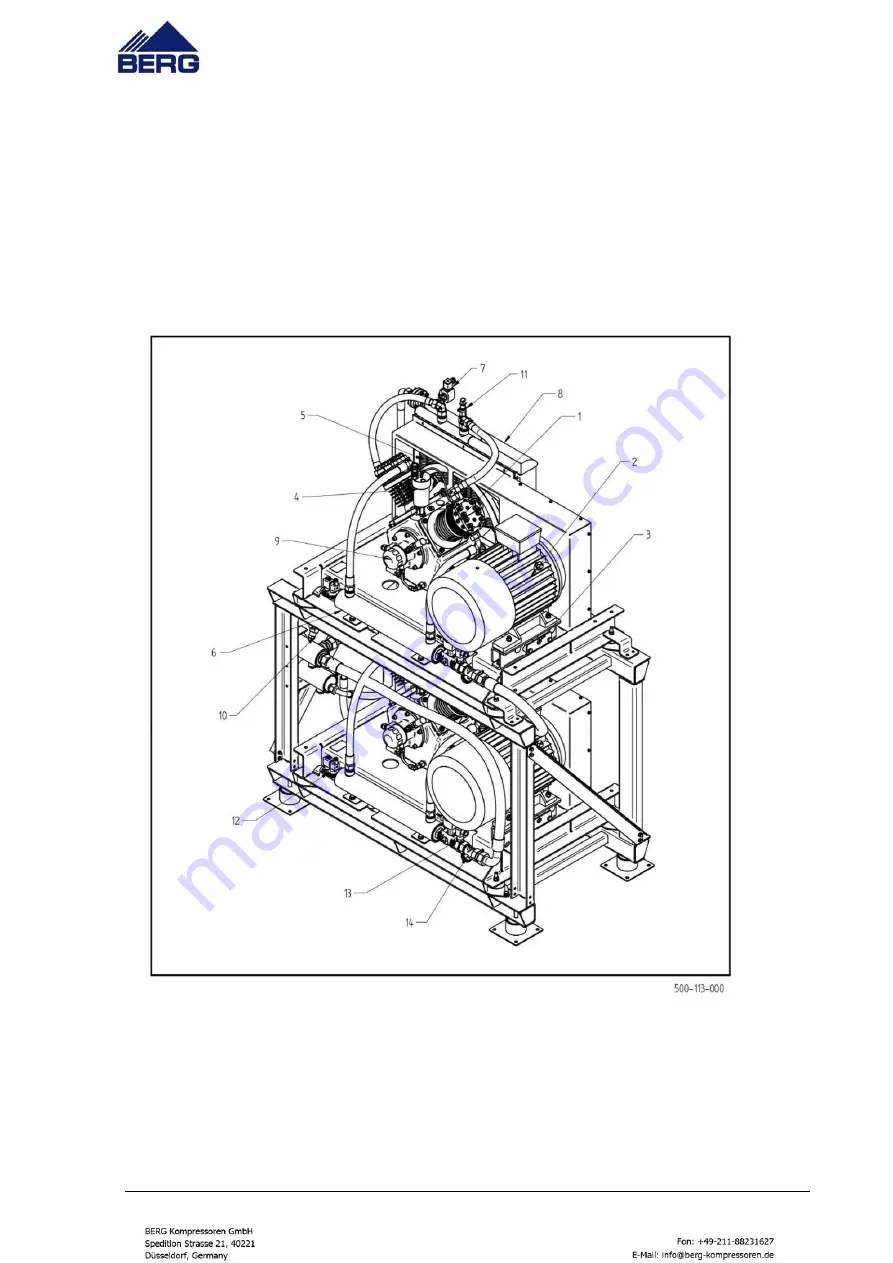

Booster KOMPBERG BKB22 TWIN

1. Compressor 8. Cooler

2. Electric motor

9. Oil filter

3. Belt tensioner

10. Pressure transmitter

4. Breather 11 Safety

valve

5. Belt transmission cover

12. Solenoid valve - unload

6. Intake collector

13. Solenoid valve - intake

7. Solenoid valve

14. Mesh filter