4.2. Requirements concerning electrical system

-

The compressors are designed to be supplied by a four-conductor 400 V AC, 50 Hz power line.

-

The compressors are equipped with PE terminal.

No.

Compressor type

Power lead cross

sectional area

mm

2

Fuse size

NH gL/gG, 500V, 100kA

D gL/gG, 500V, 50kA

1

KOMPBERG ZX90

PE

200

-

The power cable cross sectional area should be matched to the current drawn by the

compressor.

-

The compressors can only be operated on three-phase earthed system (TN).

-

The compressor must be supplied from the distribution board equipped with a slow blow fuse

and circuit-breaker that enables the compressor power supply to be completely disconnected.

-

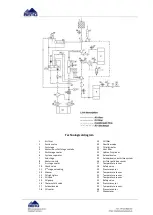

Electrical connection of the compressor should be performed in accordance with the attached

electrical diagram.

-

Only authorised personnel or qualified electrician is allowed to perform electrical connections.

-

Use the required safety measures in accordance with the suitable regulations.

-

Calculate the power cable cross sectional area and fuse sizes according to the local regulations

and operating conditions.

-

Below there are presented the recommended power cable cross sectional areas and fuse sizes

for standard compressors.

-

A user takes a full responsibility for selection of an electrical system and power supply connection

for the compressor.

Recommended power cable cross sectional area and fuse sizes

4.3. Compressed air connection

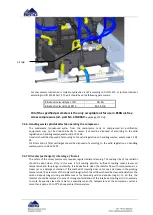

It is recommended to use galvanized steel or plastic tubes for the compressed air

system.

When the compressed air treatment equipment (filters, dryer) is installed, the existing

compressed air piping should be replaced with a new one, unless air supplied

previously wastreated by similar equipment.

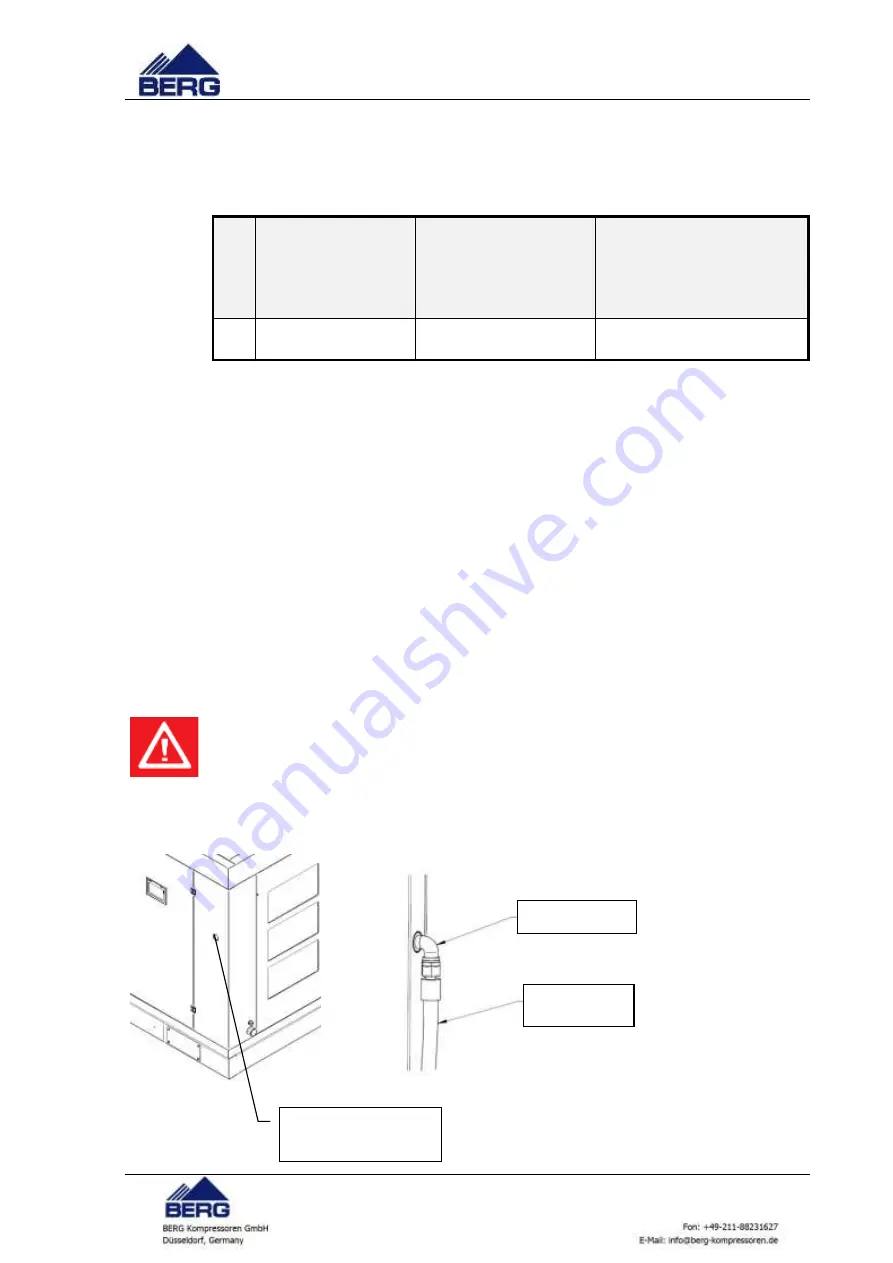

Each BERG compressor should be connected to the compressed air network by using a

flexible conduit or flexible connector (axial expansion joint) and shut-off valve.

Compressed air

outlet

Pneumatic

hose

Elbow