7.3.

Basic components requiring maintenance. Maintenance operations.

7.3.1. Air filter cartridge

The filter cartridge can't be soaked in oil or other liquids.

Change the filter cartridge every 2000 work hours or once a year. In case of highly contaminated

ambient air, the cartridge must be cleaned or replaced more frequently

.

Maintenance procedure:

-

Stop the compressor and close the pressure conduit valve. Reduce the overpressure in the screw

assembly body to reach the atmospheric pressure (see the microprocessor controller).

-

Safeguard the compressor from restarting by an unauthorized person, e.g. by cutting power

supply off.

-

Open the filter cover and carefully remove the dust.

-

Take the cartridge out, clean it or replace with a new one.

-

Rinsing: do not apply force, avoid damaging the cartridge. Clean contact surfaces of

gaskets.

-

Purging: purge the external surface of the cartridge with dry compressed air, at the

pressure up to 0.5 MPa, askew from the inside and outside.

-

Replace the filter cover taking care to position it properly.

-

Start the compressor and check for correct operation.

No particles of dirt or dust should get from the suction side into the screw stage.

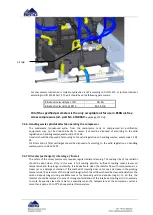

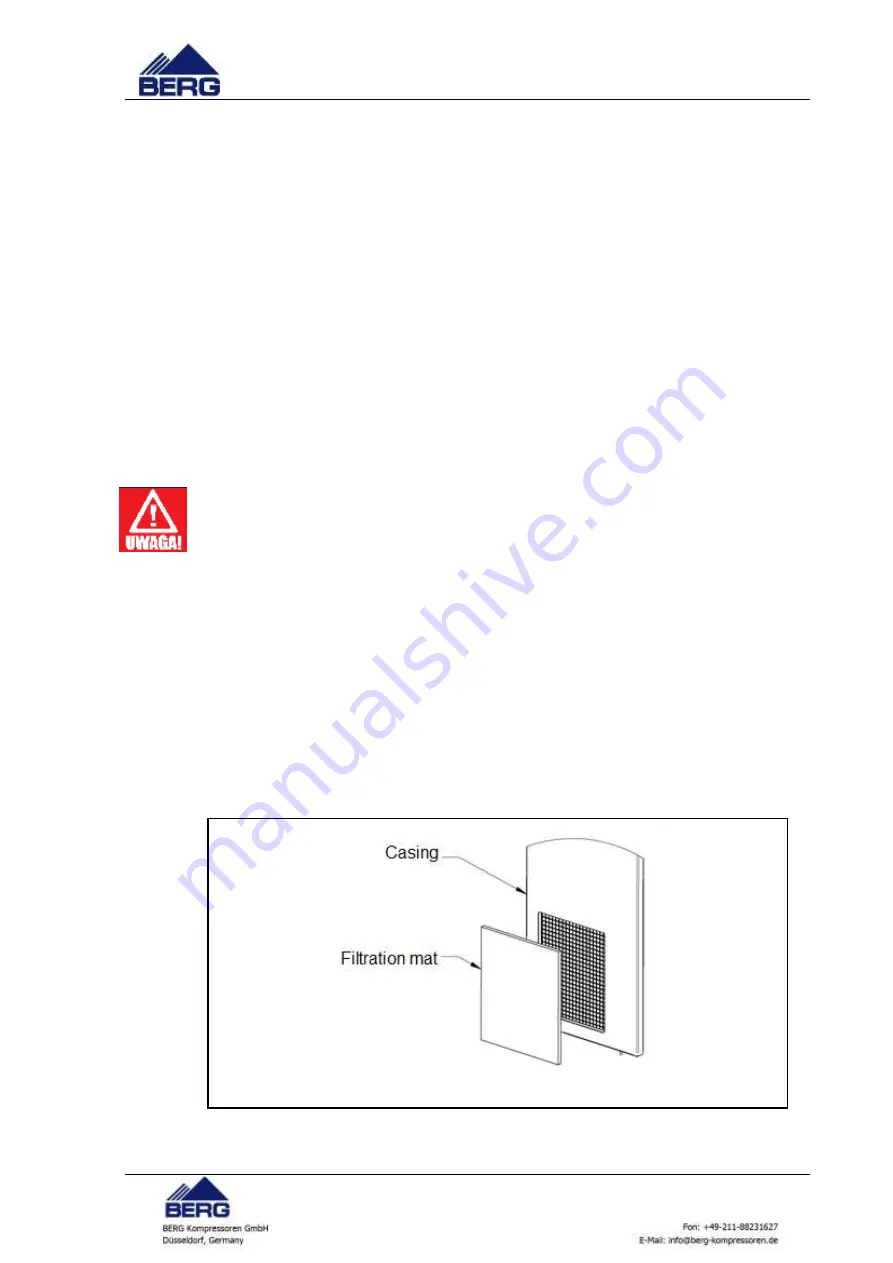

7.3.2 Cleaning or replacing the filter mats.

Filter mat is placed at the inlet into the housing. If the filter mat get dirty, cooling of the

compressor may be insufficient.

Maintenance operations:

-

Carefully, without tools, remove the filter mat from the housing.

-

Thoroughly vacuum or flick the mat. In case of heavy dirtiness, the mat can be

washed in water with detergent.

-

If it’s impossible to clean the mat or the mat is damaged, it should be completely

replaced.

-

Carefully placed the filter mat in the housing.

Filtration mat exchange