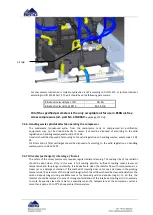

7.3.3. Oil filter

Change the oil filter every 8000 hours or once a year.

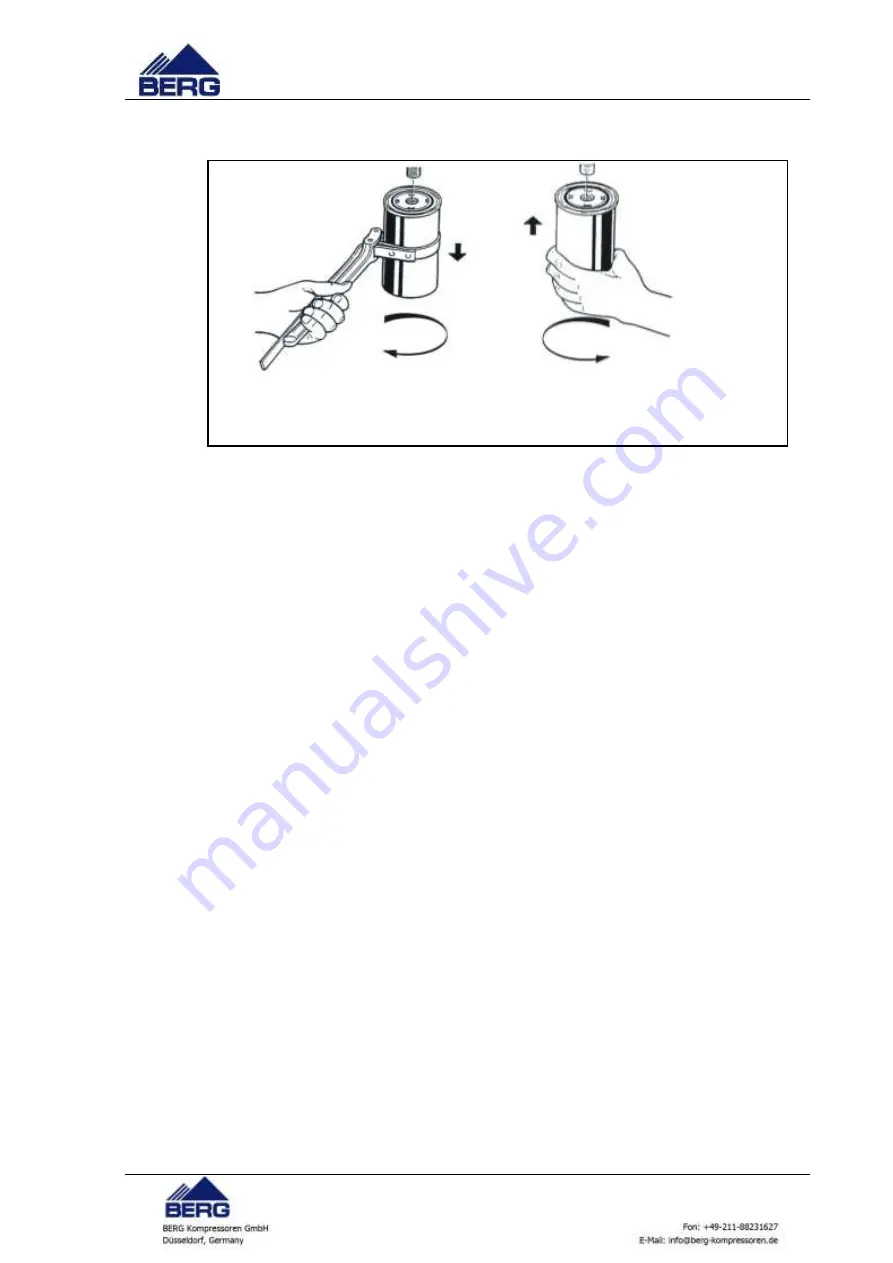

screwing out screwing in

Oil filter - maintenance

Maintenance procedure:

-

Stop the compressor and close the pressure conduit valve. Reduce the overpressure in the screw

assembly body and oil system to reach the atmospheric pressure (see the oil pressure

manometer / microprocessor controller).

-

Safeguard the compressor from restarting by an unauthorized person, e.g. by cutting power

supply off.

-

It is advised to use a special spanner to replace the filter. Caution

–

hot oil!

-

Rub some oil onto the gasket of the new filter before screwing it in. Fill the new filter, held

vertically, with the same type of oil as that in the separator tank. Then screw the filter in by hand,

without using any tool.

-

Start the compressor and check for leaks.

7.3.4. Oil level

Sufficient oil level in the oil receiver is of critical importance for trouble-free performance of the

compressor.

Oil check intervals:

-

after prolonged compressor off-time,

-

every 100 hours.

Procedure:

-

check oil level after 1 minute from the compressor stop,

-

the oil should be above the middle line of the sight glass (during normal use when the cooler is

full of oil at all times).