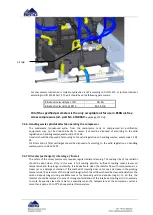

Maintenance procedure:

-

Stop the compressor, close the pressure conduit valve.

-

Lower the overpressure in the screw assembly body till reaches the atmospheric pressure (to

lower the overpressure inside the screw assembly body wait about 5 minutes after switching off

the compressor,

-

Safeguard the compressor from restarting by an unauthorized person, e.g. by cutting power

supply off.

-

Dismantle the radiator.

-

Clean and remove impurities.

-

Reassemble all disassembled components.

-

Fill (top up) the compressor with oil.

-

Carry out a operating test for approx. 3 to 5 minutes.

-

Stop the compressor, check the oil level and top up if necessary.

7.3.8.

. Electric motor

When the compressor is running, check the motor operation by paying attention to the following:

-

Operating noise,

-

Excessive vibration,

-

Excessive current consumption

–

protection activation in the electrical cabinet,

-

The condition of the fixing screws,

-

A degree of fouling.

The motor (compressor) should be stopped immediately in case of:

-

Overheating,

-

Smoke or burningsmell,

-

Excessive vibration,

-

Bearing noise.

The machine can be restarted after removing the cause of any failures

.

Periodic motor inspections:

The motor inspection should be performed at least once per 2 years.

The inspection should be performed by the in-house personnel or properly qualified personnel

from specialized companies.

Any repairs or special inspections should be performed by the specialised workshop or the

manufacturer service.

Replacement or lubrication of the motor bearings must be performed in accordance with the

manufacturer’s recommendations. The permissible hours of the bearing operation to the

replacement or lubrication are presented in the table below. When any symptoms indicating the

bearing damage occur (unusual noise or increased temperatures), contact the service

immediately.

7.3.9

Safety valve

The safety valves fulfil an important function in pressure equipment and systems. They require

particularly careful and professional service. Any operational shortcomings may damage the

Hours of operation until the performance of service operations

Motor power

Bearing type

Hours of operation

Operations

3-22 kW Maintenance-free

40000 h Replacement

30-55 kW Maintenance-free

20000 h Replacement

75-90 kW Requiring maintenance

4000 h Lubrication

110-200 kW Requiring maintenance

3000 h Lubrication