Translated user manual V3_EN

METO-SWT

7030.XX.XXXX

17 / 52

7.3

Minimum requirements for the pipe rail system

The rails (normally heating pipes) must have an external diameter of either 51 mm or 45

mm and a wall thickness of at least 2 mm. The minimum material specifications for the

pipes is as follows: Steel 37 (S235JR). The distance between the pipe rail system

supports may not exceed 1.25 metres. When combining pipes with a diameter of 45 mm

to a track width of 42cm, the distance between the rail supports should not exceed 1

metre. The pipe rail supports used should be in accordance with, or equivalent to the

following specifications: 1.5 mm thick steel base plate with reinforcing profile - base plate

width of at least 115 mm - the length should be such that the base plate protrudes at least

70 mm from the two vertical supports which carry the load of the pipes. The centre-to-

centre distance between the pipes should be at least 42 cm. The pipes must be properly

secured, precisely installed and with a maximum tilt of no more than 2

in both length or in

width. The pipes must also be properly attached to the supports and the concrete track .

Loose fitting pipes must not be used! At the pipe ends (in front of the wall) there should be

an end-stop welded on that is at least 5 cm high - at the end of each season check

whether the stops are not flat, folded, crooked or broken. A soil test bore should be carried

out using probing equipment (see the Health & Safety catalogue applicable in the

Netherlands). It should have a so-called cone value on the top layer of more than 0.4 Mpa

(62 psi).

The use of rail systems not covered by the H&S catalogue applicable in the Netherlands is

permitted on the condition that a stabilisation test is carried out in accordance with the

said H&S catalogue from which it appears that the pipe rail trolley / pipe rail system

combination would be stable. Furthermore, the supports for these other pipe rail systems

must be installed no more that 1 metre apart, and the tilt must not exceed 2 degrees in

both length and width.

The tubes are similar or at least equal to the specifications given in the table below.

The conditions for the axle load stand in the table below.

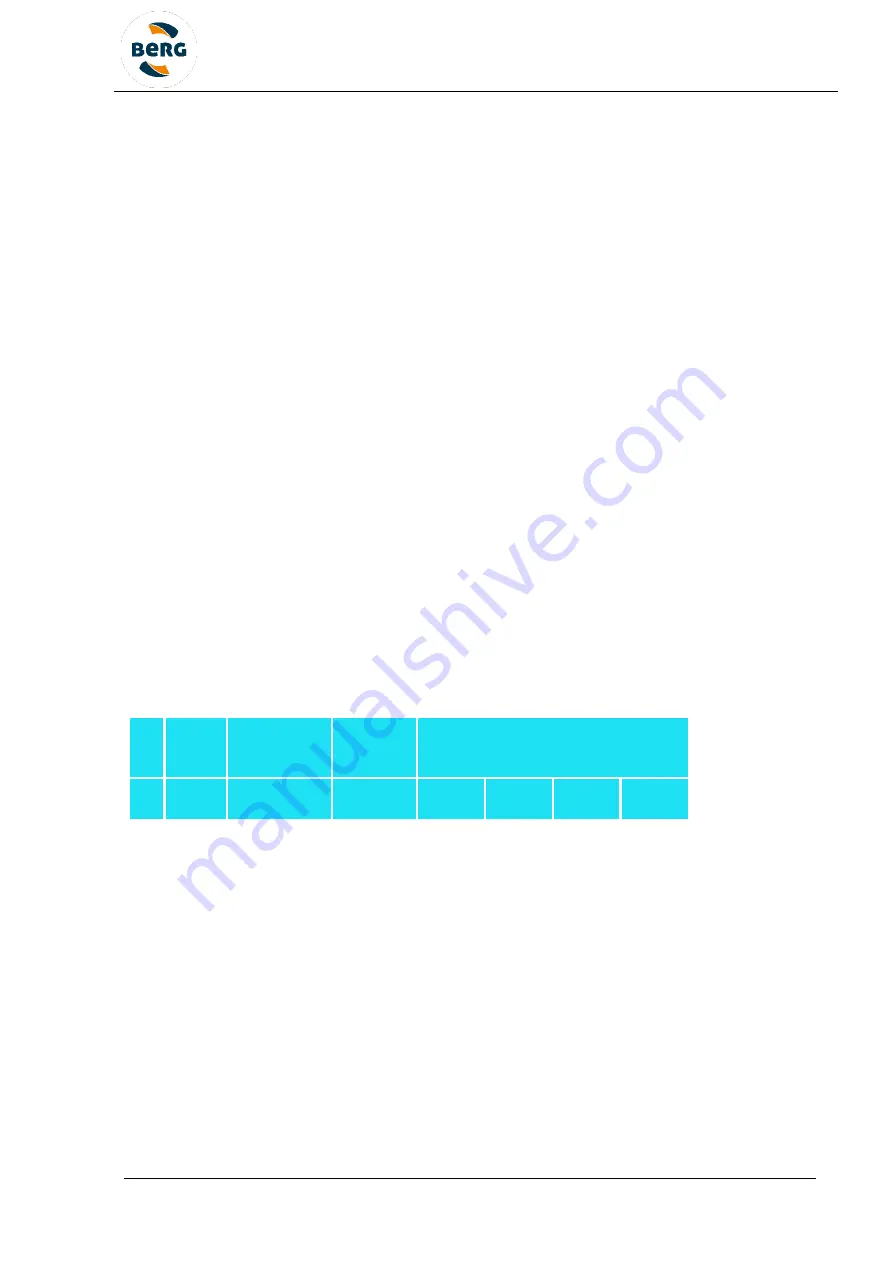

Cat.

Track-

width

Tube-

diameter /

thickness

Support-

distance

Permissible axle load at

center to center size

Cat.

[mm]

[mm]

[mm]

420mm

[kg]

500mm

[kg]

550mm

[kg]

600mm

[kg]

1

420 t/m

600

51 / 2,25

max. 1000 507

548

573

593

2

420 t/m

600

51 / 2,25

max. 1250 406

438

458

475

3

420 t/m

600

45 / 2

max. 1000 345

372

372

403

4

420 t/m

600

45 / 2

max. 1250 276

298

276

323

Quality steel 37 (St37)

Wheelbase between 62.5% and 125% of the support distance.

All values for other pipe and tube rail supports should be calculated separately.

Source: The Dutch health and safety catalog in force in the Netherlands

https://agroarbo.nl/catalogus/buisrailsysteem/