11

The PowerCenter has a limited current carrying

capacity so we recommend that you use a DC

Source Center whenever you have multiple XL.1

wind turbines. DC Source Centers are available

from Bergey Windpower.

Additional Design Guidance:

1. If you have multiple XL.1 turbines and

PowerCenters, do not connect more than

one wind turbine to one PowerCenter.

2. Connect multiple PowerCenters to a DC

Source Center via the PowerCenter’s bat-

tery terminals.

3. Do not connect the PowerCenter to an-

other controller that could disconnect the

PowerCenter from the batteries. The

PowerCenter should not be disconnected

from the battery when there is input from

the wind turbine.

B. Location

The PowerCenter must be installed indoors and

should be located relatively close to the battery

bank. Do not install the PowerCenter outdoors; it

is not waterproof.

C. Mounting:

The PowerCenter needs to be mounted vertically

to a wall, or other support structure, so that air can

pass unobstructed through the passive cooling

channel behind the enclosure. We recommend

setting the height of the LED’s at eye level if pos-

sible so that the system status lights will be easi-

est to read.

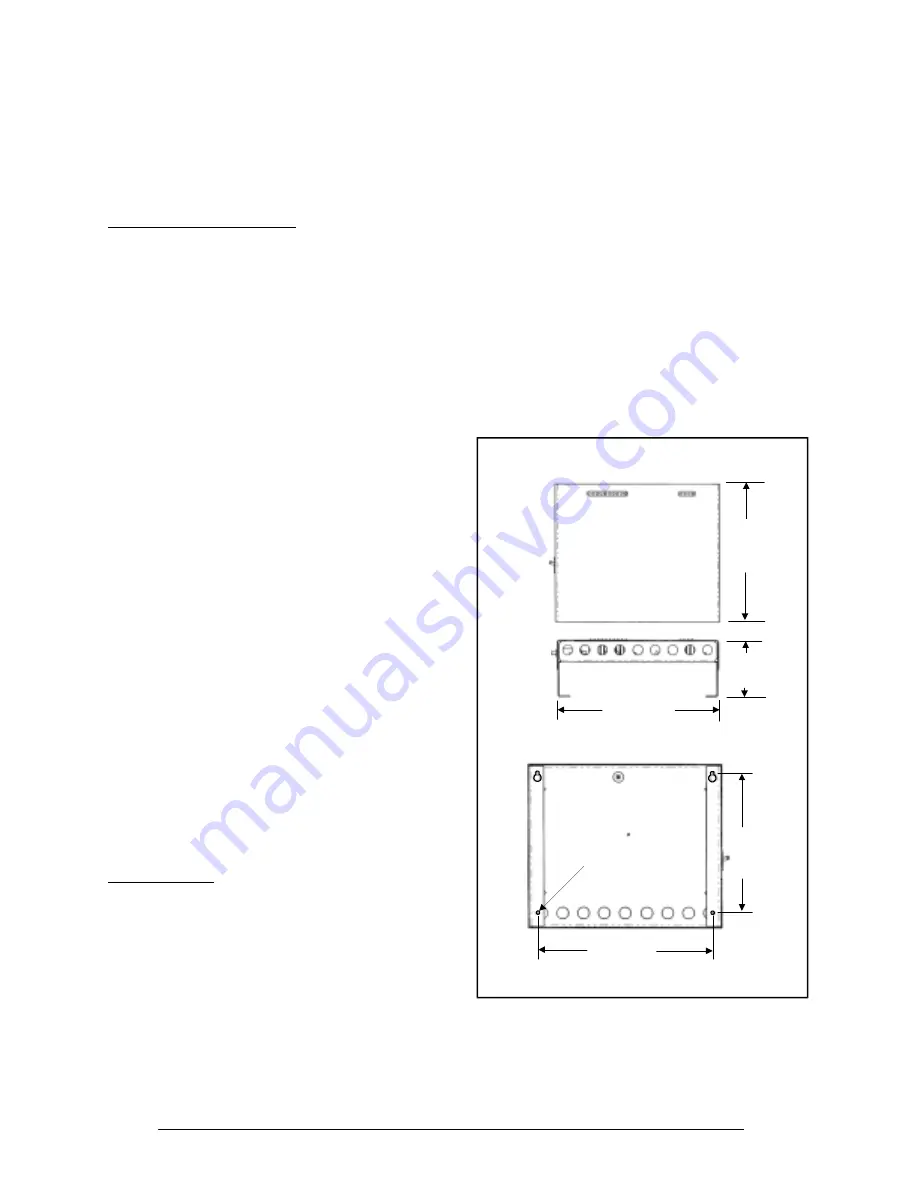

The enclosure dimensions and mounting layout

for the PowerCenter are shown in Figure 12. The

PowerCenter should be mounted with four M4

(0.157” dia.) screws. We recommend the follow-

ing procedure:

Tools Required:

Pencil

Carpenters

level

Drill with ~ 2 mm or 0.09” dia. drill bit

(4) M4, 1/8”, or 5/32” screws

Screwdriver

Procedure:

Step 1:

Mark the mounting hole locations using the Pow-

erCenter enclosure as the template. Use a car-

penters level to check the levelness of the enclo-

sure before marking the holes.

Step 2:

Drill small (~ 2.5 mm or 0.1 in diameter) pilot holes

for the mounting screws.

Step 3:

Screw the top two mounting fasteners into the wall

until ~ 6 mm (1/4”) of the shank extends out from

the wall.

Step 4:

Remove the PowerCenter cover and place the

PowerCenter enclosure on the two upper mount-

ing fasteners. Slide the enclosure down such that

the fasteners are placed at the top of the inverted

“T-slots”.

Figure 12, PowerCenter Mounting Dimensions

390 mm

15 3/8“

15.375“

128 mm

5.0“

337 mm

13 1/4“

13.25“

Bottom View

Front View

Enclosure Dimensions

267 mm

10 1/2“

10.5“

333 mm

13 1/8“

13.125“

3.8 mm

0.150“

Diameter

4 Places

Mounting Hole Layout

Equalize Button

Back View

Step 5:

Install the bottom two mounting fasteners, and

then tighten the top two fasteners.

Summary of Contents for 24 VDC B

Page 19: ...18 Appendices ...