8

Tilt-up Type Towers:

If you have a tilting

tower, such as the BWC Tilt.Tower, the following

procedure is recommended:

Tools Required:

17 mm box end wrench

17 mm socket and ~ 300 mm (12”) ratchet

drive

8 mm socket or wrench

pliers

crimpers for wiring terminals (U-shaped

crimp preferred over straight crimp)

thread locking compound (like Loctite 242)

tape measure, 12 ft.

Procedure:

Step 1:

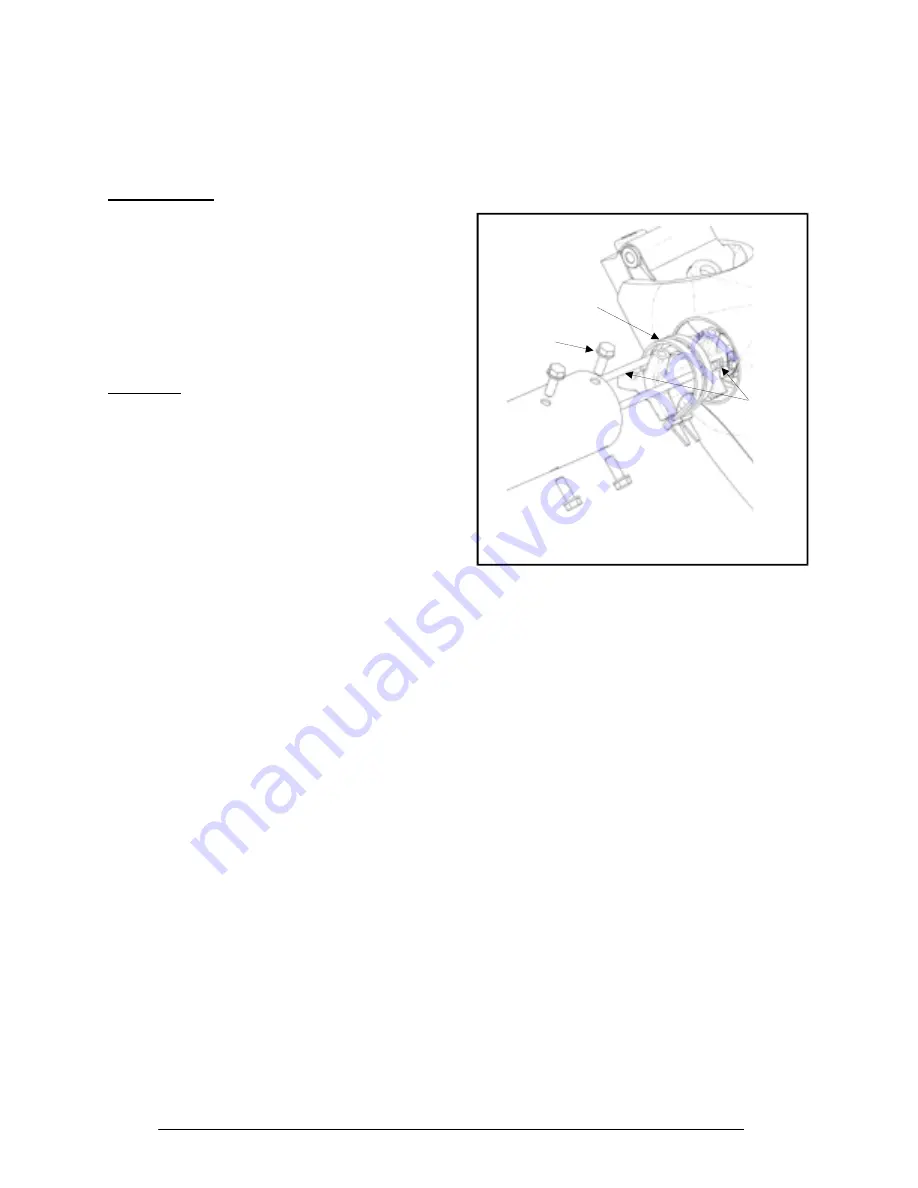

With the tower tilted down, place the powerhead

of the wind turbine near the top end of the tower.

The tower wiring is connected to the XL.1 wind

turbine at the slip-ring using two small screws and

ring terminals crimped to the two conductors. Cut

the outer insulation on the wire back about 60 mm

(2.5 in). Strip the insulation off the outer 12 mm

(1/2 in) of each conductor and crimp on the ap-

propriate ring terminals (several sizes are pro-

vided to match possible wire sizes). Attach the

two power conductors to the slip-ring assembly

with the screws provided. The polarities of the

connections are marked. If your conductors are

color-coded we recommend making note of the

colors connected to positive and negative leads.

The slip ring assembly is not designed to support

the weight of the down-tower wire. A strain reliev-

ing installation is required, as shown in Figure 7.

Use the two nylon cable ties provided to secure

the tower wiring to the tower adapter casting. Af-

ter completing the connections, pull on the tower

wire to make sure that it is secure before mount-

ing the wind turbine on the tower.

Step 2:

Raise the tower about 1 meter (3 ft) off the ground

to provide room to assemble the XL.1 turbine. We

recommend fashioning a temporary support stand

to hold the tower up during turbine assembly.

Step 3:

Mount the wind turbine tower adapter to the top of

the tower using the six M10 x 1.5 bolts and six

washers. We strongly recommend applying Loc-

tite 242 (Thread Locking Compound) to the

threads prior to installation to reduce the likelihood

of loosening due to vibration. We recommend

using a torque wrench to achieve the proper fas-

tener torque on the tower mounting bolts. The

recommended toque is 54 N.m (40 ft-lbs).

Power

Cables

Nylon

Cable

Ties

Turbine

Mounting

Bolts

Figure 7, Turbine Mounting

Step 4:

Complete the wiring to the PowerCenter before

adding the blades. This is recommended so that

you can test the DC polarity of the wiring by spin-

ning the alternator by hand. It is very important

that the polarity [positive (+) and negative (-)] is

correct when the turbine is connected to the Pow-

erCenter. The best way to ensure this is to com-

plete the wiring and then test the polarity with a

Volt-Ohm-Meter.

Wiring recommendations are provided in Section

7 and in Appendix 1, section D. Turning the alter-

nator by hand will provide enough voltage to make

this check. Carefully mark the positive and nega-

tive electrical leads for later reference.

Step 5:

Turn the XL.1 powerhead upward so that the al-

ternator is facing up. Attach the blades as shown

in Figure 8 using the M10 hardware provided. We

recommend bolting one blade up solidly and leav-

ing the other two somewhat loose while you check

the tip-to-tip blade distance. We recommend

checking, and adjusting as necessary, the blade

tip spacing to ensure that the blade tips are

equally spaced. This step will help make the wind

Summary of Contents for 24 VDC B

Page 19: ...18 Appendices ...