PowerSync II

Operator’s Manual & Installation Instructions

Page 8

Rev: 1.1

1.405.364.4212 /

5. Operation

This equipment is a UL 1741 certified Utility Interactive Inverter and complies with the requirements of

IEEE1547 which is the standard for interconnecting distributed resources with electric power systems. It

will not operate in an off-grid or backup power configuration.

The normal operation of the inverter is as follows: When single phase utility power is applied to the

output of the inverter, the display will power up and a message stating that the unit is initializing is shown.

If there are no faults, i.e. grid voltage and frequency are in tolerance, a countdown timer set for 5 minutes

(300 seconds) starts before the inverter is ready to transfer power to the utility grid. The inverter will

automatically transfer power to the utility when turbine input AC voltages is in the range of 30VAC to

400VAC.

As the heatsink heats up after exporting significant power for a period of time the internal cooling fans will

activate. The inverter is be able to operate at full power continuously if provided with adequate ventilation

and the local ambient temperature stays below 45ºC (113ºF). If the ventilation is compromised or the

heatsink temperature exceeds 60°C, the inverter will automatically reduce its output power.

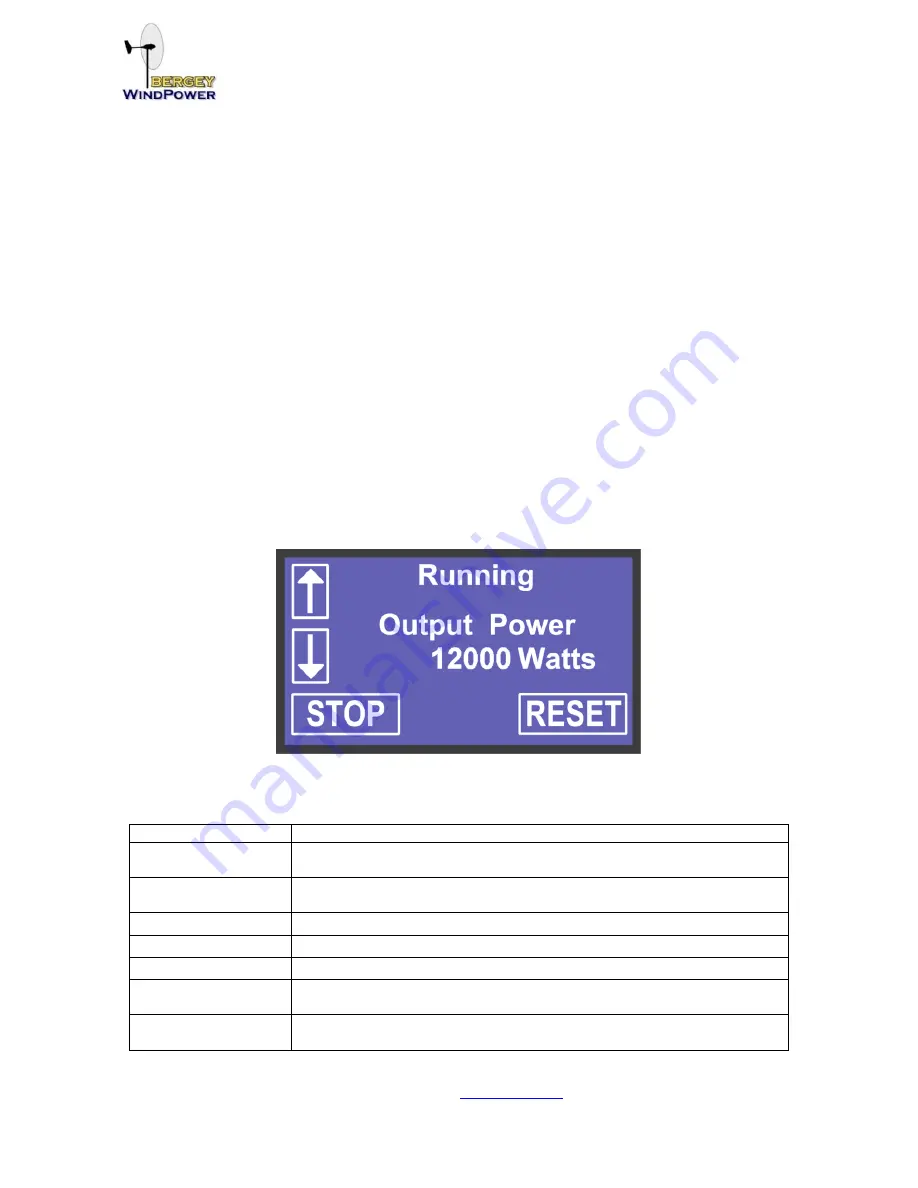

6. Touch Screen Display

The touch screen display located on the front panel of the enclosure provides manual over-ride and

status of the inverter’s operation. The touch screen display also provides a Stop and a Reset button.

The Stop button is used when it is desired to disconnect the inverter from the power grid and the wind

turbine. After Stop is pressed the inverter will remain in a powered-up stand-by mode until Reset is

pressed or Grid voltage is removed. When Reset is pressed the inverter will resume normal operation.

The status of the inverter

’s operation is shown on the lines one and two of the display. The following table

lists the status messages that may appear.

Status Message

Description

Waiting

Initializing

The inverter has been reset or that the 5 minute countdown delay is in

progress

Waiting

For Wind

The voltage from the turbine is lower than the factory set auto-start

voltage threshold

AC Running

The active rectifier is regulating the internal DC Boost voltage

Running

The inverter is transferring power to the utility grid

Fault

A fault has occurred. See fault messages

Manual Stop

Press Reset

The manual stop button has been pressed

Fault Limit

Press Reset

Three faults have occurred in an hours time