11. Maintenance and Care

11.

03

every 6 years

replace pressure hoses

enter replace-

ment into main-

tenance plan

*)

in one-shift operation (8 hours per day) yearly, in case of several shift operation

10.3

Lubrication of the bearings

A proper lubrication of your machine is absolu-tely necessary to ensure a trouble-free operation and to

avoid expensive repairs.

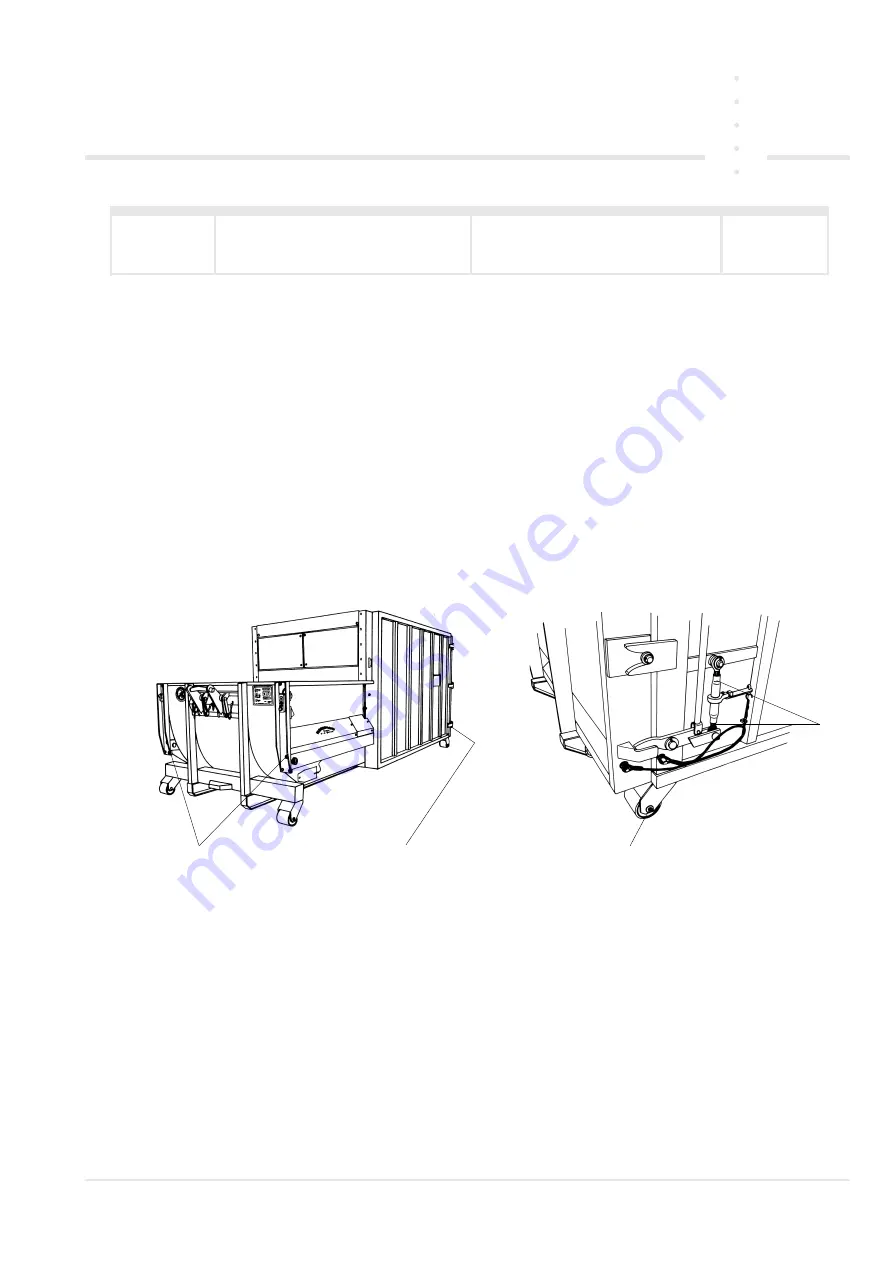

Your COMPACTION BOX is equipped with lubricating points at the bearing points of the cylinders

(pos. 1, 2x) at the door hinges (pos. 2, 3x) and at the container wheels (pos. 4, 4x or 8x) for this

purpose.

Lubrication should be carried out every 14 days; using a grease gun apply a generous quantity of

resin-free grease.

We would recommend the use of lithium base or natrium base grease KP 0 F -30 or GP 0 F -30.

One can, however, also use greases of an equally good quality with the following characteristics :

Temperature range for use

- 30 to + 80°C (-22°F to 176°F)

Walkpenetration

DIN ISO 2137

355 to 385 ( NLGI - class 0)

Drop point

DIN ISO 2176

approx. 150°C (302°F)

Corrosion protection

DIN 51 802

corrosion degree 0

Basic oil viscosity at 40°C (104°F) DIN 51 562

approx. 130 mm²/s (0,2 sq.in./s)

3

Illustration standard version

(deviations are possible)

2

1

4

Summary of Contents for ALPHA-PACK-BIN

Page 2: ......

Page 6: ......

Page 16: ......

Page 20: ......

Page 28: ......

Page 34: ......

Page 50: ......

Page 52: ......

Page 53: ...10 Dimensions 10 01 Illustration standard version deviations are possible ...

Page 54: ......

Page 60: ......

Page 64: ......

Page 66: ......

Page 68: ......

Page 70: ......

Page 72: ......

Page 74: ......

Page 76: ......

Page 78: ......

Page 80: ......

Page 82: ......

Page 84: ......

Page 86: ......

Page 88: ......

Page 90: ......

Page 92: ......

Page 94: ......

Page 96: ......