600-C601 RevB_EN 1 / 15

®

LIMITED WARRANTY

TABLE OF CONTENTS

Product Identification ……………………..............1

Safety Information ………………………................2

Model specification ………………………………….…2

Installation ……………………...............................3

Initial Start-Up …………………….........................4

Seasoning the Cooking Surfaces…..................4

Operating Instructions (Electronic Control)…4

Program Instructions (Electronic Control)…...5

Operating Instructions (Mechanical Control).5

Daily Cleaning……………………...........................6

Spring adjustment…………………….....................7

Exploding View…………………….........................8

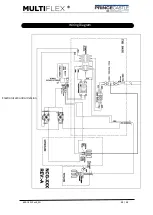

Wiring Diagram ……………………...................... 13

Error code table…………………………….. ……… ...15

This product is warranted to be free from defects in material and/or

workmanship for a period of 1 year from date of original installation, not to

exceed 18 months from the date of manufacture.

Any component which proves to be faulty in material and/or workmanship

will be replaced or repaired (at the option of Prince Castle, Inc.) without

cost to the customer for parts and labor. This warranty covers on-location

service (i.e. trip charges and/or mileage). Travel mileage is limited to 100

miles (200 Kilometers) round trip (one trip warranty) from an authorized

service agency or its sub-service agency.

This warranty is subject to the following exceptions/conditions:

• Use of any non-genuine Prince Castle parts voids this warranty.

• All labor shall be performed during regular work hours. Overtime

premium (the incremental amount) will be charged to the customer.

• Damage caused by carelessness, neglect and/or abuse (e.g. dropping,

tampering, or altering parts, equipment damaged in shipment, by fire,

flood or an act of God) is not covered under this warranty.

• All problems due to operation at voltages other than that specified on

equipment nameplates are not covered by this warranty. Conversion to

correct voltage is the customer’s responsibility.

• Normal adjustments as outlined in this manual are not covered under

warranty.

• This equipment must be serviced by Prince Castle Authorized Service

Agency or a Prince Castle Service Technician during the warranty period.

• Wearable items such as (springs, Teflon sheets, bearings) are not

Included under warranty.

OPERATION MANUAL

NCG9&8 Series

Product Identification

Prince Castle LLC (China)

5 floor, Building 8, No. 300 Dingyuan Road, Songjiang District, Shanghai, China, Zip Code 201616

Tel: +86-021-6040-1728 www.princecastle.com

DISPLAY

SET BUTTON

PRODUCT 1 &

UPPER ARROW

BUTTON

PRODUCT 2 &

LOWER ARROW

BUTTON

PRODUCT 3 BUTTON

PRODUCT 4

BUTTON

TEMPERATURE

BUTTON/LOGO

TOP HEATER

ON/OFF

INDICATOR

LIGHT (1-4)

HEATING

INDICATOR

LIGHT (TOP)

HEATING

INDICATOR LIGHT

(BOTTOM)

NCG9

NCG8