6

7

Repeaters can also be used to get additional fieldbus lines at a low cost if placed at PLC output.

Each line is independent from the others and therefore a problem on a line does not affect the

others.

BERNARD CONTROLS can supply weatherproof or explosion proof repeaters.

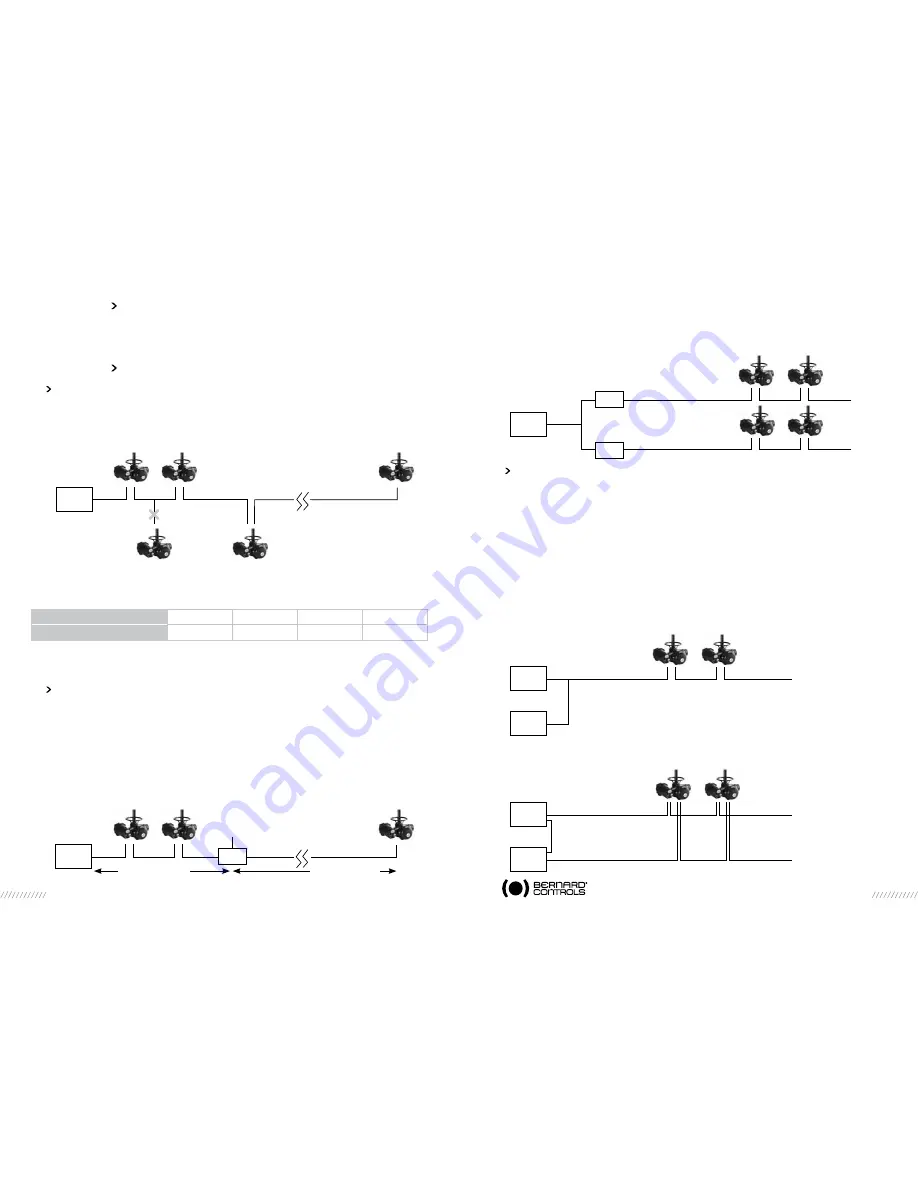

Redundancy

Redundancy of the fieldbus system is to continue to communicate with the actuators even if a line fails.

In order to achieve this function all the communication system is doubled. The PLC uses two output

Profibus ports, the fieldbus line is doubled and the actuator interface board is doubled.

If repeaters are required, the repeaters are doubled.

The redundant INTELLIBUS module is designed according to Profibus Guide Line «Specification Slave

Redundancy» N° 2212, that includes a redundancy communication channel (RedCom) and special

redundancy extensions. One of the slave module acts as primary and the other one as backup.

In fact the Profibus system allows different level of redundancy:

Flying redundancy

is a redundancy of the connection point, the actuator interface is doubled and

also the PLC interface. The line (Profibus cable) is a single line.

The redundant actuator interface INTELLIBUS has 2 channels, each one is connected to the Profibus line.

The address is not the same for each channel. One address is chosen from 1 to 125, the other one

is this a 64.

System redundancy

is the most common system with all communication system doubled as des-

cribed first.

Transmission baud rate

< 93.75 kBit/s

187.5 kBit/s

500 kBit/s

1,5 MBit/s

Maximum line length

1200m

1000m

400m

200m

PLC

Note:The PLC is also at

the end of the line and

needs a termination

To make a detour use

2 cables, up and down.

End of line actuator

Termination is «on»

No ramifications

3.6

EmERgENCy SUPPLy

The actuator is normally supplied by the mains but in case of loss of power supply

an emergency supply could be used to continue to communicate through the fieldbus. This emergency

supply needs 24V DC 4W.

3.7

PROFIBUS DP ARCHITECTURE

Single line

The Profibus cable coming from the PLC is connected to the first actuator then the Profibus cable

links this actuator with the next one and so on. All actuators are connected to the line one after

the other until the last one. No return to the PLC is required.

To avoid reduced performance in transmission don’t add ramifications on the line

Maximum line length is 1200m (3600ft). Maximum number of actuators by line is 31.

Maximum line length is reduced according to the communication speed:

An end of line termination must be connected at each end of line actuator. (see § 3.3)

Repeaters

Adding repeaters modules allows to increase both the number of actuator on the line and total

line length. Each repeater uses one connection point therefore this limits the number of actuators

by segment to 30 units and allows to lengthen the line by 1000m.

According to the type of repeater, it is possible to use until 9 repeaters and to extend the line

as long as 10 km.

Maximum number of actuators depends of PLC capacity, addressing capacity and number of segment

with repeaters. The maximum on one Profibus line is 124.

The important advantage of the repeater compared to other repeater-free technologies is to keep

the communication speed unaffected and therefore to get a very short response time.

Repeater

power

supply

Segment 1000m long

30 actuators

Segment 1200m long

31 actuators

Repeater

PLC

Repeater

Repeater

PLC

Single line

Redundant PLC

Redundant

INTELLIBUS

Redundant

INTELLIBUS

Primary

PLC

Backup

PLC

Redundant PLC

Redundant line

Redundant

INTELLIBUS

Redundant

INTELLIBUS

PLC

Master 1

PLC

Master 2