12

13

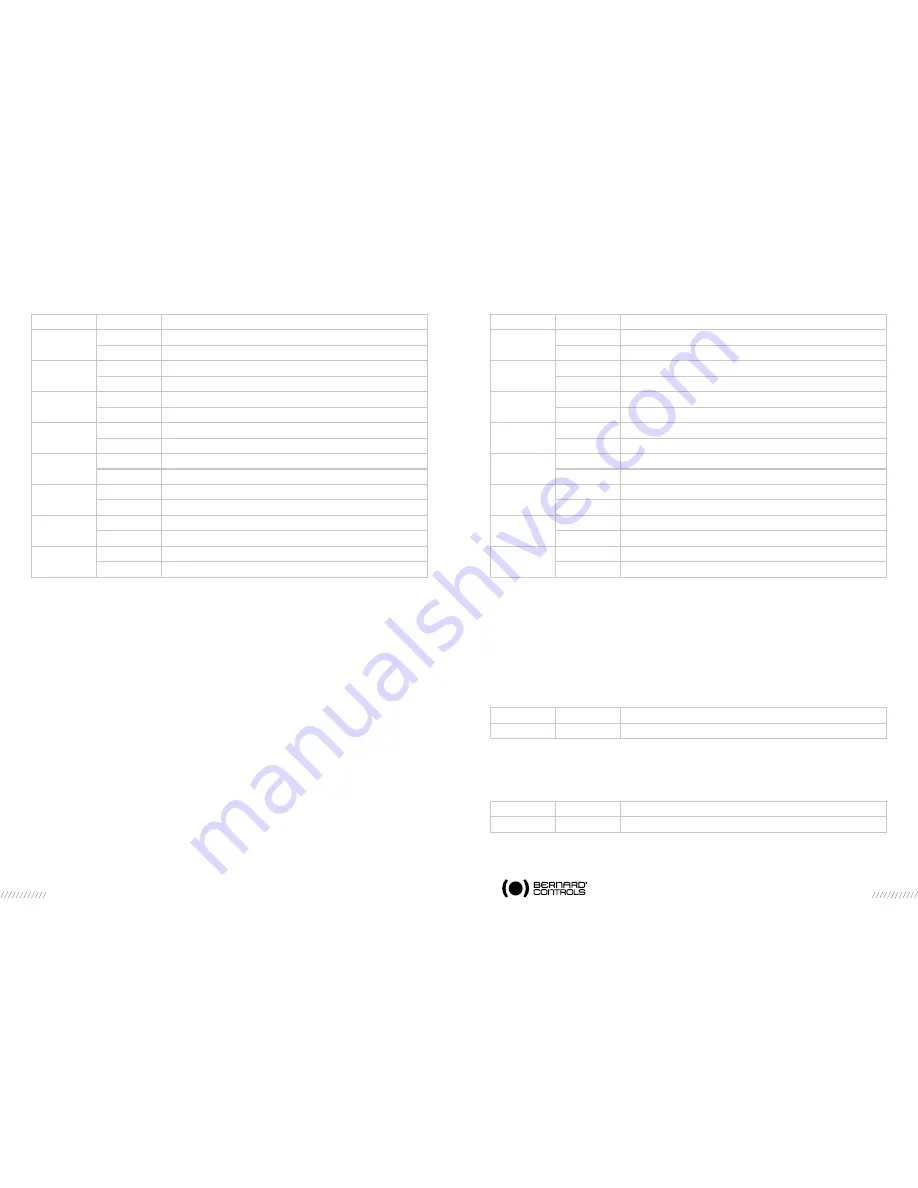

Address 1 : Indications

ACTUATOR OPENING/CLOSING: the actuator is operated in opening/closing direction

HANDWHEEL ACTION: the handwheel has been actuated since the last electrical operation

ACTUATOR RECEIVES AN EMERGENCY COMMAND ESD: The actuator is not available because

it receives an emergency command which overrides all other commands.

ACTUATOR RUNNING: the actuator is operated in opening or closing direction

ACTUATOR FAULT INDICATION: The actuator is not available due to a following event:

Motor thermal overload, lost phase (in case of 3ph supply), locked rotor.

Including additional faults(refer to NR1151 to configure):

Selected option: selector in local, selector in off.

Options: jammed valve, emergency command, command inhibit, overtravel.

If the actuator is power off, then the Intellibus interface is power off and there is no communication

on Profibus.

POSITION OR TORQUE POWER SUPPLY FAULT: receives no information from the position or

torque sensor.

Address 2 : alarms

LOCKED MOTOR OPEN/CLOSE: The motor locked in the opening/closing direction.

MOTOR THERMAL OVERLOAD: The motor thermal contact tripped. The actuator will be again

available as soon as the motor will cool.

LOST PHASE: In 3 phase, a phase is missing. No start allowed.

OVERTRAVEL ALARM: Position overshoot > 5% after motor shut down.

DIRECTION OF ROTATION OPEN/CLOSE: Opening/closing direction of rotation discrepant

BATTERY LOW OR IS NOT PRESENT: In case of battery option the battery should be replaced

because of too low voltage or the battery is missing.

Address 3 : Running torque in %

RUNNING TORQUE: Indication of the instantaneous torque. 100% is the maximum actuator rated

torque

Address 4: Actuator position feedback

ACTUATOR POSITION FEEDBACK: 0%= closed, 100%= open

Bit n°

Value

Description

Bit 0

0

ACTUATOR NOT OPENING

1

ACTUATOR OPENING

Bit 1

0

ACTUATOR NOT CLOSING

1

ACTUATOR CLOSING

Bit 2

0

NO HANDWHEEL ACTION

1

HANDWHEEL ACTION

Bit 3

0

NO ESD COMMAND

1

ACTUATOR RECEIVES AN EMERGENCY COMMAND ESD

Bit 4

0

THE ACTUATOR IS NOT RUNNING

1

ACTUATOR RUNNING

Bit 5

0

ACTUATOR AVAILABLE

1

ACTUATOR FAULT INDICATION

Bit 6

0

NO POSITION SENSOR POWER SUPPLY FAULT

1

POSITION SENSOR POWER SUPPLY FAULT

Bit 7

0

NO TORQUE SENSOR POWER SUPPLY FAULT

1

TORQUE SENSOR POWER SUPPLY FAULT

Bit n°

Value

Description

Bit 0

0

NO LOCKED MOTOR OPEN ALARM

1

LOCKED MOTOR OPEN

Bit 1

0

NO LOCKED MOTOR CLOSE ALARM

1

LOCKED MOTOR CLOSE

Bit 2

0

NO MOTOR THERMAL OVERLOAD ALARM

1

MOTOR THERMAL OVERLOAD

Bit 3

0

NO LOST PHASE ALARM

1

LOST PHASE

Bit 4

0

NO OVERTRAVEL ALARM

1

OVERTRAVEL ALARM

Bit 5

0

NO DIRECTION OF ROTATION OPEN ALARM

1

DIRECTION OF ROTATION OPEN ALARM

Bit 6

0

NO DIRECTION OF ROTATION CLOSE ALARM

1

DIRECTION OF ROTATION CLOSE ALARM

Bit 7

0

NO BATTERY FAULT

1

BATTERY LOW OR IS NOT PRESENT

Bit n°

Value

Description

Bit 0 to 7

0-150

RUNNING TORQUE IN %

Bit n°

Value

Description

Bit 0 to 7

0-100

ACTUATOR POSITION IN % OF OPENING