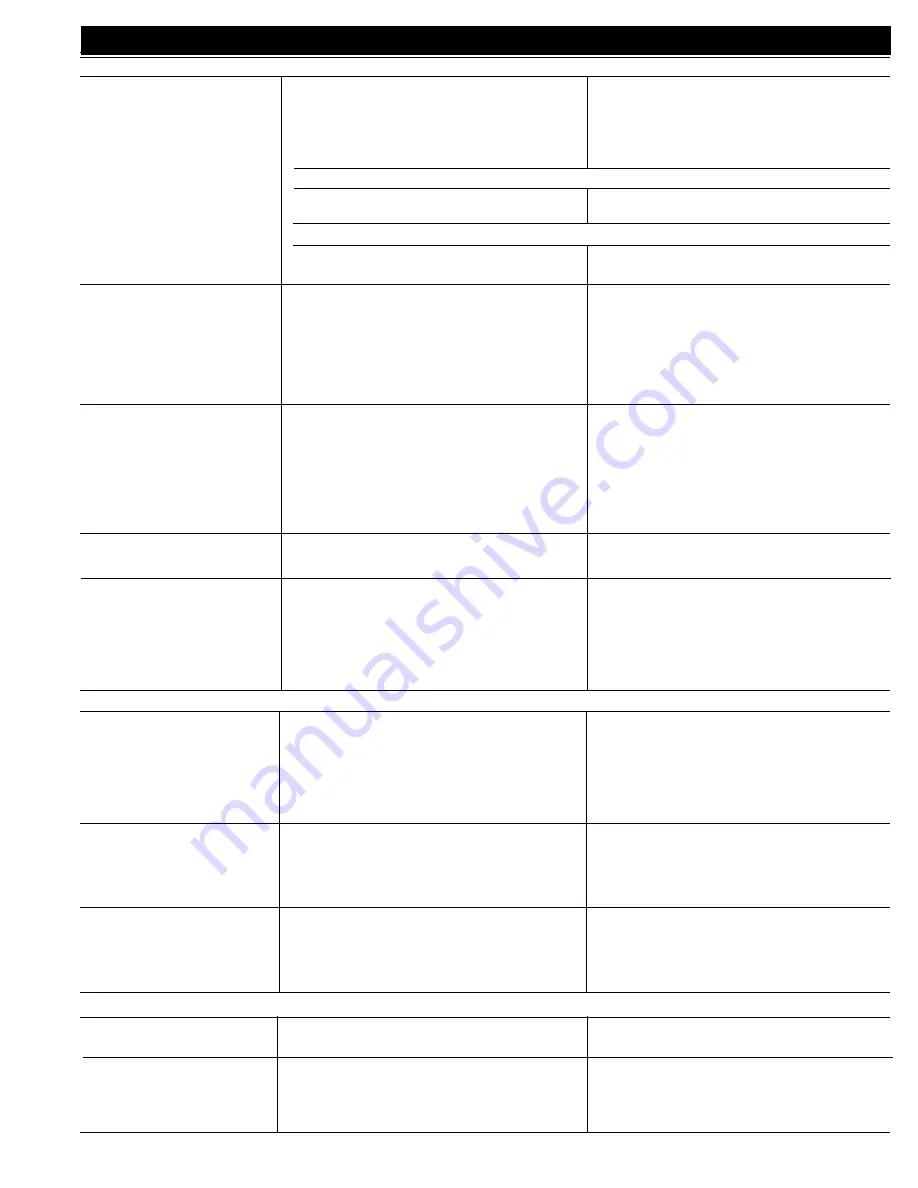

-13-

• Air stream too weak

• Air steam hits obstruction

• Negative pressure

• Shaft rotating inside fan

• One motor not operating

• Nozzle not angled out far enough

• Unit too powerful

• Air movement too cold

• Pushing air outside building

SEE

AIR

IS NOT HITTING FLOOR

SYMPTOMS

• Switch turned to “ON” position

• Thermostat not set properly

• Coils burned out due to lack of air

• Automatic reset thermal cutout failed in open position

• Manual reset thermal cutout tripped (if supplied)

• Adjust nozzle to proper position, adjust motor speed;

see installation instructions

• Remove obstruction or reposition air curtain (move out

3/8” for every 1” up from the door)

• Relieve negative pressure by providing makeup air

• Tighten set screws

• Repair or replace motor

• Adjust nozzle angle to outside

• Adjust motor speed

• Add auxiliary heat to overcome wind chill factor

• Adjust discharge angle back into building, adjust motor

speed

• Replace switch or check wiring

• Change thermostat setting

• Correct airflow problem; replace coils

• Replace automatic thermal cutout

• Reset manual thermal cutout

AIR IS NOT HITTING

FLOOR

UNEVEN AIR

EXCESSIVE AIR

MOVEMENT AT DOOR-

WAY

ELECTRICALLY HEATED MODELS

NO HEAT

MINIMAL HEAT

EXCESSIVE HEAT

STEAM/HOT WATER HEATED UNITS

EXCESSIVE HEAT

MINIMAL HEAT

NO AIR

• Power supply line open (no power)

• Fuse blown/circuit breaker tripped

• Motor overload tripped

• Failed switch

• Check power source, check method of control in ON

position

• Replace fuse(s)/reset breaker

• Internally protected motor - should reset automatically

after cool-down, if not, replace motor.

• Replace switch

MOTOR RUNNING/FANS ARE NOT ROTATING

MINIMUM AIR

ELECTRICAL CONTROLS NOT FUNCTIONING WHEN DOOR IS OPEN

SYMPTOMS

REMEDY

CAUSE

• Broken or damaged flexible hub

• Shaft rotating inside fan

• Selector switch is in off position

• Door limit switch not operating

• Air directional discharge vanes mis-adjusted

• Inadequate intake clearance

• Blower motor operates below speed

• Fan rubbing against housing

• Fan wheels clogged with dirt

• Fan in backwards

• Replace fan sleeve/reengage coupling

• Tighten set screws/tighten fan on shaft

• Turn switch to “ON” position

• Repair or replace limit switch

• Adjust vanes to proper position, see instructions

• Move air curtain or remove obstruction

• Provide adequate space for air curtain

• Improper voltage

• Free fan from housing

• Clean and vacuum fan wheels

• Check fans for blade curve toward discharge

• Thermostat in wrong location - thermostat too

close to discharge

• Improper voltage

• Thermostat not set properly

• Low entering air temperature

• Incorrect speed range

• Thermostat in wrong location

• Thermostat not set properly

• Insufficient air over coil

• Improper voltage

• Too high steam/hot water pressure

• Inadequate air flow, fins plugged up, dirty coils

• Insufficient removal of condensation (steam)

• Not enough steam pressure/water temperature too

low

• Intake air below design temperature

• Move thermostat away from air stream

• Supply proper voltage

• Change temperature setting

• Based on unit temperature rise, reduce speed

• Set dip switch to electric heated speed range

• Move the thermostat closer to air stream

• Change temperature setting

• Remove restriction on intake

• Supply proper voltage

• Reduce steam pressure/hot water flow

• Clean intake and coils

• Increase trap size

• Raise pressure for steam/increase water flow

• Increase steam pressure/increase water flow

X. TROUBLESHOOTING