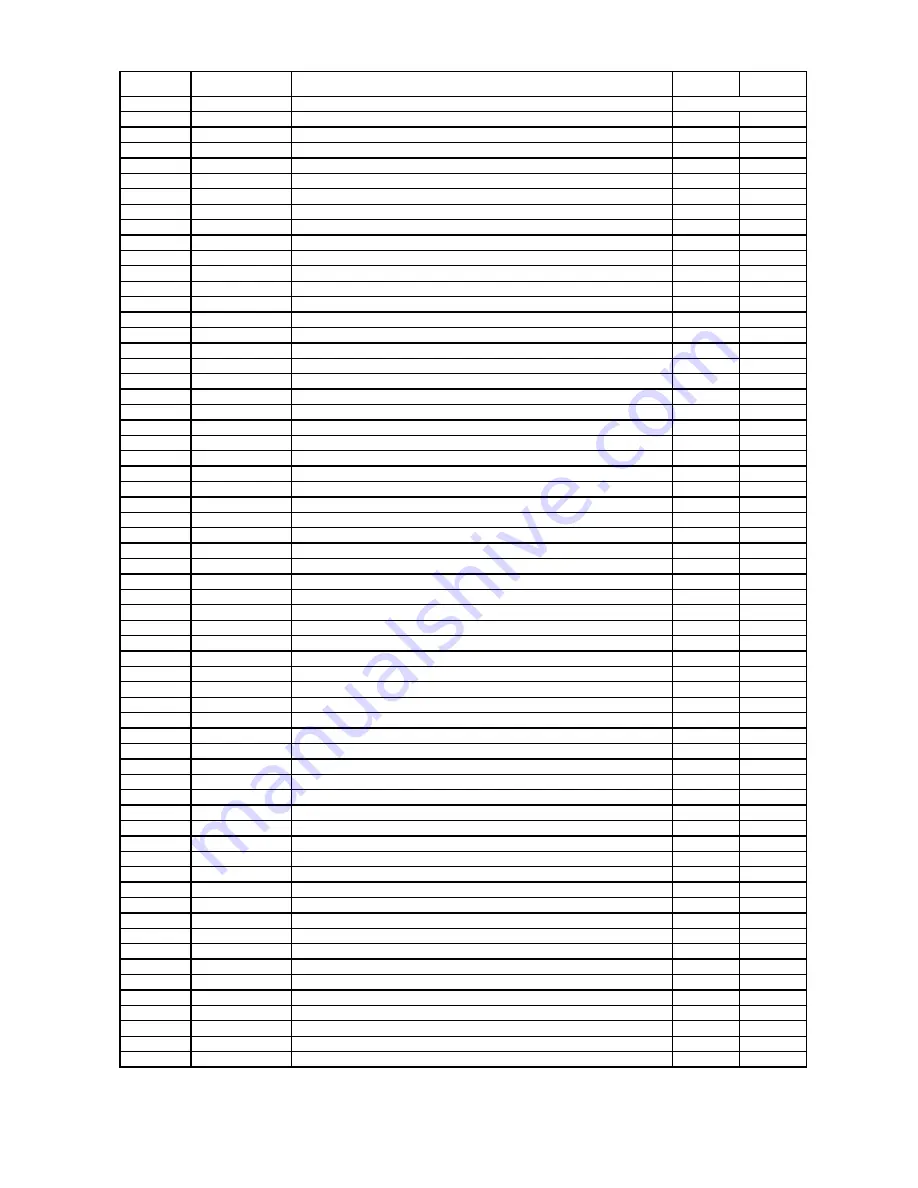

SPARE PARTS LIST

C36500X C36600X

NUMBER

COMPONENT

DESCRIPTION

1

601639

CIRCUIT DIAGRAM

1

1

601641

CIRCUIT DIAGRAM

1

11

202387

BURNERS FLASK

2

2

18

202432

PART FOR DUAL WOK AND SEMI RAPID BURNERS

1

22

202397

LOAD BEARING BOTTOM

1

1

55

404198

WORKTOP FRONTGUARD

1

1

80

504160

COVER FOR SMALL FLAME SPREADER

1

1

81

504161

COVER FOR MEDIUM BURNER

2

3

82

504162

COVER FOR RAPID BURNER

1

1

85

504187

COVER IN FOR DUAL BURNER FLAME SPREADER

1

1

86

504186

COVER OUT FOR DUAL BURNER FLAME SPREADER

1

1

160

202262

BRIDLE FOR FIXING GAS VALVES

1

1

385

306024

SPRING FOR SPARK PLUG

6

7

424

415071

SPARK PLUG FOR DUAL BURNER

2

2

425

415054

SPARK PLUG 350MM

2

3

426

415057

SPARK PLUG 700MM

2

2

430

415065

ACCUMULATOR 6U

1

430

415064

ACCUMULATOR 4U

2

473

408069

SIMMER PLATE

1

1

561

508025

TERMOCOUPLE MM300

2

2

562

508021

TERMOCOUPLE MM600

2

3

566

508034

TERMOCOUPLE ULTRA-RAPID BURNER

2

2

648

601991

TERMINAL SEPARATOR

1

1

670

504128

SMALL FLAME SPREADER

1

1

671

504129

MEDIUM FLAME SPREADER

2

3

672

504130

RAPID FLAME SPREADER

1

1

675

504189

ULTRA RAPID FLAME SPREADER

1

1

702

408058

ADAPTER FOR WOK BURNER PAN SUPPORT

1

1

715

604064

DAISYCHAIN SWITCH

1

715

604065

DAISYCHAIN SWITCH

1

760

510507

SMALL BURNER

1

1

761

510508

SEMI RAPID BURNER

2

3

762

510509

RAPID BURNER

1

1

764

510511

DUAL BURNER

1

1

884

502179

GAS VALVE BY PASS 029 SMALL/DUAL INNER

2

2

885

502148

GAS VALVE BY PASS 036 SEMI-RAPID

2

3

886

502180

GAS VALVE BY PASS 047 RAPID

1

1

887

502150

GAS VALVE BY PASS 065 DUAL OUTER

1

1

917

200336

STAINLESS STEEL SIDE

2

2

940

201168

FIXING FOR WORK TABLE

2

2

943

308031

BUMPER FOR C.I. GRIDS AND DISHWARMER

4

4

965

408052

CAST IRON PAN SUPPORT 2 BURNERS

2

3

960

408053

CAST IRON PAN SUPPORT 1 BURNER

1

1041

401904

GAS VALVE KNOB

4

5

1046

401961

DUAL IN KNOB

1

1

1047

401962

DUAL OUT KNOB

1

1

1143

910666

UPSTAND KIT

1

1

1602

210475

CONTROL PANEL

1

1602

210476

CONTROL PANEL

1

1603

309119

BRIDLE FOR FIXING GAS VALVES/THERMOSTAT

3

4

1615

202395

CONTROL SUPPORT

1

1

1624

200316

WORK TABLE

1

1624

200317

WORK TABLE

1

1627

501645

GAS COLLECTOR

1

1627

501644

GAS COLLECTOR

1

1628

501646

TUBE FOR RIGHT FRONT BURNER

2

2

1631

501647

TUBE FOR RIGHT BACK BURNER

1

1

1801

501648

TUBE FOR LEFT BACK BURNER

1

2

1805

501650

TUBE FOR EXTERNAL DUAL BURNER

1

1805

501655

TUBE FOR EXTERNAL DUAL BURNER

1

1806

501651

TUBE FOR INTERNAL DUAL BURNER

1

1806

501654

TUBE FOR INTERNAL DUAL BURNER

1

QUANTITY