23

SURFACE COOKING

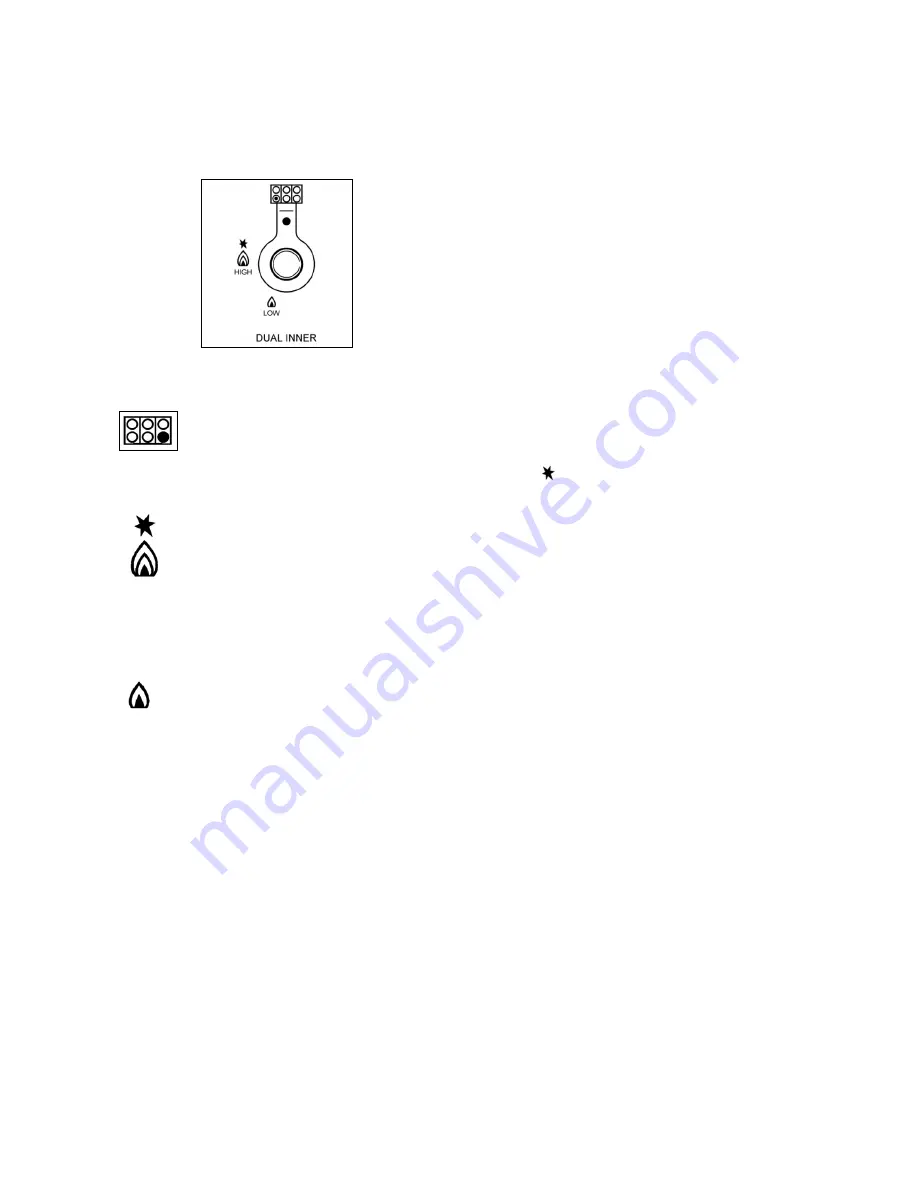

SYMBOLS

Burner position (in this case

front right burner).

Maximum

temperature

setting / Recommended

control knob position for

burner ignition

Minimum temperature setting

SURFACE BURNER OPERATION

THERMOCOUPLE SAFETY VALVE

Each surface burner of a Bertazzoni range is

equipped with a thermocouple safety device.

The thermocouple opens the flow of gas to the

burner only when hot. Should the flame go off,

the thermocouple will immediately close the gas

flow to the burner eliminating any risk to your

home.

For faster activation of the thermocouple, always

light the burners on maximum power. This will

allow the thermocouple to reach the optimum

temperature in the fastest time.

ELECTRIC IGNITION

To activate the electric ignition, simply turn the

control knob counter

‐

clockwise to maximum

power ((

position). Press the knob to start the

flow of gas and the ignition spark. The spark will

released at the metal tip of the white ceramic pin

located on the side of the burner. Once the flame

is on, release the control knob gently.

If the flame turns off, repeat the above

procedure.

The dual power

‐

burner is composed by two

burners (inside and outside). Each burner is

activated by a separate control knob. The two

burners can be operated separately or together

for maximum power. To activate the power

‐

burner, turn on the central burner first, then turn

on the external ring.

ATTENTION: do not ignite burners if the black

burner cap is not installed or not centred. The

flame will be irregular.

MANUAL IGNITION

Manual ignition is always possible even when the

power is cut off or in the event of power failure.

Turn the control knob counter

‐

clockwise to the

MAXIMUM position. Light the flame with a

kitchen lighter or with a match.