34

NOZZLES OR FILTER DIRTY

- Clean and rinse dirty filter or nozzles using a brush and water.

To do this, use the brush/wrench (BERTHOUD reference 779.354).

Never blow into a nozzle.

CLEANING THE DELIVERY FILTER(S)

(figure 16)

- This is situated between the pump and the distribution unit after the regulating valve, near the motorized

valves.

- Provides additional filtration.

- The circuit must be isolated before cleaning the filter cartridge.

- Set all handles in position

, (figure 17).

- To remove the filter cartridge, unscrew the cartridge (1) (figure 16) using a 27 mm spanner (not supplied with

the machine).

The filter cartridge needs to be cleaned after each application. Grease the seals.

Reminder: The original factory-fitted filter cartridge is 4/10 mesh. (8/10 mesh is available in spare

parts for liquid fertilizer).

Summary of Contents for BOXER II 3000 A

Page 2: ...2...

Page 4: ...4...

Page 6: ...6...

Page 12: ...12...

Page 20: ...20...

Page 21: ...21 OTHER SPRAYER FUNCTIONS...

Page 27: ...27 13 3 2 1 14 2 1...

Page 29: ...29 1 15...

Page 30: ...30...

Page 37: ...37 3 2 18...

Page 39: ...39 MAINTENANCE DIAGRAMS...

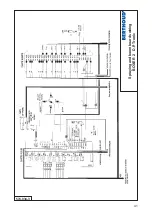

Page 41: ...41 574 034 3 Spraying and boom boards wiring BOXER 2 D P Tronic R...

Page 42: ...42 574 033 3 Cab connector box AXIALE front boom wiring BOXER 2 DP TRONIC R...

Page 43: ...43 574 037 3 Cab connector box EKTAR front boom wiring BOXER 2 DP TRONIC R...

Page 44: ...44 574 036 3 Cab connector box AXIALE front boom wiring BOXER 2 R...

Page 47: ...47...