36

- The solvents in the mixtures can cause some seals to swell.

- If, in spite of good maintenance, the ball valves should become blocked, it is possible to unblock them simply

(see figure 18) by doing the following:

- unscrew the two nuts (2) to access the internal adjustment part (3) which you must unscrew by 1/8 of a

turn, until the spherical ball turns normally, without great effort,

- reassemble the parts in reverse order and check the valve is tight enough.

MAINTENANCE OF PLASTIC VALVES

- After each use, rinse the pipework thoroughly, operating the machine for several minutes with clear water.

- Drain the pipework, particularly if there is a risk of frost.

- Keep the hinges on the arms, the bearing surfaces of the hinge cam and the uprights on the fixed frame

greased.

- Touch up the paintwork as necessary.

SERVICING THE BOOM

For more information on the spraying boom,

refer to the latter's technical sheet in the booklet's flap.

Summary of Contents for BOXER II 3000 A

Page 2: ...2...

Page 4: ...4...

Page 6: ...6...

Page 12: ...12...

Page 20: ...20...

Page 21: ...21 OTHER SPRAYER FUNCTIONS...

Page 27: ...27 13 3 2 1 14 2 1...

Page 29: ...29 1 15...

Page 30: ...30...

Page 37: ...37 3 2 18...

Page 39: ...39 MAINTENANCE DIAGRAMS...

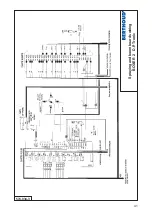

Page 41: ...41 574 034 3 Spraying and boom boards wiring BOXER 2 D P Tronic R...

Page 42: ...42 574 033 3 Cab connector box AXIALE front boom wiring BOXER 2 DP TRONIC R...

Page 43: ...43 574 037 3 Cab connector box EKTAR front boom wiring BOXER 2 DP TRONIC R...

Page 44: ...44 574 036 3 Cab connector box AXIALE front boom wiring BOXER 2 R...

Page 47: ...47...