7

SELF PROPELLED SPRAYER

- Self propelled base with IVECO Diesel engine liquid

cooled. 6 cylinders, 163 HP, 5.9 liters.

(option engine IVECO 6 cylinders, 200 HP, 5.9 liters).

- Welded frame in square profile.

- GRP tank with flotting gauge, capacity 3000/4000

5% with baffle and separate 400-liter rinsing

tank.

- Diesel tank 210 Iiters. Oil tank 105 liters.

- Ground clearance 1.15 m (option 1.30 m).

- Fixed track width 1.80 m to 2.70 m.

(in option: Variable wheel track by sliding axles

1.80 m to 2.25 m or 2 m to 2.40 m).

- Wheelbase 3.65 m.

- 4 wheel drive by hydrostatic drive POCLAIN with

brakes et variable delivery pump REXROTH and

hydro-mecanic locking system.

- 4 wheel steering with hydrostatic steering by Orbitrol

DANFOSS.

- Wheels 270/95 R 48 adjustable rims

(options: 300/95 R 46 - 460/85 R 38 - 480/70 R 38 -

520/70 R 38 - 520/85 R 38 - 580/70 R 38).

- Speed road: 27.5 km/h. Speed field: 13.7 km/h.

- Hydraulic brakes on the rear wheels.

- Multicontrol joystick for forwad speed, spraying,

boom height and angle control (option for variable

geometry).

- Protected under frame.

- Panoramic pressurized/heated cab, FM/tape radio,

tinted windows, UTAC-approved windshield. Two

activated carbon filters.

- Lighting in compliance with the Highway Safety

Code.

- Gyrolight.

- Pneumatic seat.

- Sound alarm for rear movement.

- Double external control of engine speed. Double

external control of PTO.

- Two front and rear work lamps.

Options on Self propelled sprayer:

Air compressor equipment with air blow gun.

SPRAYING EQUIPMENT for

SELF-PROPELLED BOXER 3000/4000 A

Dual-turbine, rotary

DELTA pump

for double output,

enabling:

- Filling, agitation, rinse, transfert and spraying.

- Double filtering system:

- filling filter (sieve 8/10° mesh),

- delivery filter (1/4 turn filter, 4/10° mesh).

- Chemical hopper fitted on parallelogram.

- Nivelec gauge.

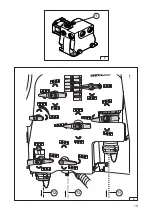

- Berlogic: Display of valve handle positions of the

various functions.

- Electronic regulation D.P.TRONIC with saved

memory.

- In cab, unic control box with:

- Control display.

- Simple cumuls management and cumuls

management on 10 fields.

- Spraying remote control by:

- 4 motorised valves with stainless steel ball

(AXIALE 24/28 and variable geometry),

- 5 motorised valves with stainless steel ball

(AXIALE 30 variable geometry, EKTAR 30,

EKTAR 32),

- 6 motorised valves (EKTAR 36 and EKTAR 38),

- 7 motorised valves (EKTAR 42),

- 8 motorised valves (EKTAR 40).

AXIALE Booms:

- Axiale 24, Axiale 24 variable geometry, Axiale 28,

Axiale 28 variable geometry, Axiale 30 variable

geometry, fitted on the front.

- Axiale suspension on pivot with springs and

oscillation shock absorbers.

- Independent folding of outer arms. Angle corrector.

7 rams on Axiale 24 and Axiale 28.

- Independent folding of outer arms. Angle corrector.

Variable geometry. 9 rams on Axiale 24/28 variable

geometry, Axiale 30 variable geometry.

- QUADRIX nozzle holder.

- 2 sets of nozzles KWIX Alumine AFX 110° Yellow

and Blue,

2 sets of liquid fertilizer nozzles KWIX Trifilet Red

and Brown.

EKTAR Booms:

- EKTAR 30, EKTAR 32, EKTAR 36, EKTAR 38,

EKTAR 40, EKTAR 42, fitted on the front.

- Pendulum suspension.

- Independent folding of outer arms. Angle corrector.

Variable geometry. 11 rams and 9 electro-hydraulic

spool valves.

- QUADRIX nozzle holder.

- Nozzles KWIX Alumine AFX 110°.

Options on spraying equipment

of BOXER 3000/4000 A:

- 6, 7, 8, 9 or 10 motorised valves with stainless

steel ball.

- Pneumatically-controlled anti-drip system.

- GESTRONIC control box, management of 99 fields,

filling programming an end of operation alarm or

auto-stop.

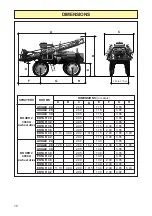

TECHNICAL CHARACTERISTICS

Summary of Contents for BOXER II 3000 A

Page 2: ...2...

Page 4: ...4...

Page 6: ...6...

Page 12: ...12...

Page 20: ...20...

Page 21: ...21 OTHER SPRAYER FUNCTIONS...

Page 27: ...27 13 3 2 1 14 2 1...

Page 29: ...29 1 15...

Page 30: ...30...

Page 37: ...37 3 2 18...

Page 39: ...39 MAINTENANCE DIAGRAMS...

Page 41: ...41 574 034 3 Spraying and boom boards wiring BOXER 2 D P Tronic R...

Page 42: ...42 574 033 3 Cab connector box AXIALE front boom wiring BOXER 2 DP TRONIC R...

Page 43: ...43 574 037 3 Cab connector box EKTAR front boom wiring BOXER 2 DP TRONIC R...

Page 44: ...44 574 036 3 Cab connector box AXIALE front boom wiring BOXER 2 R...

Page 47: ...47...