22

82.321-M - Pulvasol 1 and 2 / Pulvigne

By cleaning your sprayer regularly during and at the end of treatment seasons:

- you will avoid spraying chemical residues on the crops,

- you will ensure a good distribution of the product, while eliminating total or partial blockage of the nozzles,

- you will increase your sprayer's life.

- Filter:

Make sure that the suction filter is clean and in good condition.

- Pipes:

Look for any leaks. Check for kinks in the pipes.

- Seals and fittings:

Check that the nuts on the fittings are tight, change the seals if necessary.

- Pump:

Check the oil level.

- Nozzles:

Change them once a year or when their flow rate is 10 to 15% greater than their initial flow rate. (To do this,

use the FLOW TEST, BERTHOUD reference 765.241 - or the FLOW RATE GAUGE, BERTHOUD reference

778.887).

- Tank:

Check that there is no foreign matter in the tank.

Carry out the sprayer's maintenance operations with the engine switched

off, the ignition off and the power take-off disconnected.

PRACTICAL RECOMMENDATIONS

FOR THE SERVICING OF YOUR SPRAYER

CHECKS BEFORE SPRAY SEASON

Summary of Contents for PULVASOL 200

Page 2: ...2 82 321 M Pulvasol 1 and 2 Pulvigne...

Page 4: ...4 82 321 M Pulvasol 1 and 2 Pulvigne...

Page 6: ...6 82 321 M Pulvasol 1 and 2 Pulvigne...

Page 10: ...10 82 321 M Pulvasol 1 and 2 Pulvigne...

Page 15: ...15 82 321 M Pulvasol 1 and 2 Pulvigne 3 1 2 2 1 2 3 2 1 3 1...

Page 17: ...17 82 321 M Pulvasol 1 and 2 Pulvigne 1 2 3 4 5 4 3 2 1 4 5...

Page 27: ...27 82 321 M Pulvasol 1 and 2 Pulvigne B P 60 20 B P 105 20 13 14...

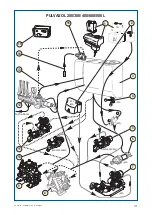

Page 29: ...29 82 321 M Pulvasol 1 and 2 Pulvigne MAINTENANCE DIAGRAMS...