After tightening, measure the front and back of the ladder to insure it is 17-1/16"

wide. Insure all ladder rods nuts are tight at this time. (Note: Do not force the slide

bars of either the panel bracket or guide frame over the edge of the ladder

into the grooves as this may spread the bars, damage the brackets, or damage

the ladder).

STEP 5. INSTALLING CABLE HOLDERS. Install stringer cable holders (#13) to the

side of the stringers approximately the third step from the bottom. Use a 1/4-20 x

1-1/4” slotted machine screw and machine screw nut to attach bracket. The back

of the fork should be facing towards the top of the ladder while the hook part of the

fork is facing towards the bottom of the ladder.

STEP 6. INSTALLING STRINGER CABLES. Slide ladder down to its lowest point

at this time. Remove-one of the stringer cables (#l 2) from the shipping fork taking

care that you don't let the cable slip from your hand. Caution should be taken when

handling the cable as the stringer spring drum was shipped from the factory with

approximately the proper spring tension already pre-wound. Bring the cable down

to the cable holder on the side of the ladder about the third step from the bottom.

Insert the cable into the fork of the cable holder (#13). Repeat this procedure for

attaching the other side. IMPORTANT: Insure the ladder doesn't creep upward from

the down position at this point. Add or remove turns of tension as needed. (see step

8).

STEP 7. INSTALLING THE HANDRAIL. Using the handrail (#3) is optional but

recommended. The handrail can be mounted on either the left hand or right hand

side. While the stairway is in its down position, the handrail posts (#4) are mounted

vertically starting inside at the bottom of the ladder with the end of the post sitting

on the bottom step resting against the edge of next step (See Figure 1.) The next

post should be mounted half way up the ladder, and the third should be mounted

towards the top of the ladder. Use #10 x 1-1/4” Pan Hd Phillips Sheet Metal Screws

provided. Next mount the handrail (#3) to the top outside posts (#4) flush with the

angle of the posts (See Figure 1.) Use #10 x 1-1/4” Pan Hd Phillips Sheet Metal

Screws provided to attach handrail to the posts.

STEP 8. ADJUSTING SPRING TENSION. Note: The spring drums come from the

factory with approximately the recommended amount of spring tension. For adding

spring tension to the stringer drums, detach the cable (#12) from the cable

holder (#13). Allow the cable to wind up slowly on to the drum (#8). Caution: do

not let the cable slip from your hand or free-wheel back on to the drum as

this will backwind or break the spring. Take the end of the cable in one hand

and pull off enough cable to cause the spring drum to rotate one turn. Firmly grasp

the drum with your other hand and re-wrap the cable onto the drum one wrap.

Reattach the end of the cable to the corresponding cable holder. To reduce spring

tension, follow the above instruction with the exception that you remove a wrap of

cable from around the drum.

STEP 9. ADJUSTING SPEED OF THE DOOR CLOSURE. To adjust the dampener

(#29) you turn the barrel of the dampener. Turn it right or clockwise to slow down

the closing of the door. Turn it left or counterclockwise to speed up the closing of

the door. Do not allow the door to travel so fast as to allow slamming, as this

will damage the stairway. Proper dampening will allow door to glide closed without

bumping or slamming.

OPERATION: To open stairway, pull down on the chain until the ladder can be

reached. Insure the catch lock (#14) has released and pull the ladder all the way

down until it stops. Allow the feet of the ladder to rest firmly on the floor and insure

the top tread is even with the attic floor.

DO NOT ASCEND THE STAIRWAY IF IT CREEPS UPWARD UNDER ITS OWN

POWER. Refer to STEP 8 for adjusting tension. Treads should be level and parallel

to the floor. TO CLOSE STAIRWAY, push ladder upward until the catch lock (#14)

engages shoulder pin on panel bracket (#10). Allow the spring drums to close the

door panel. Do not force the door panel closed.

BESSLER STAIRWAY CO. • 3807 LAMAR AVE. • MEMPHIS, TN 38118

CAUTION:

Special instructions for the Header

When installing the door and frame assembly on a model 26 or 26T, it is recommended that

shimming behind the header will give added support to the door closer bracket and piano

hinge.

The added support of shimming behind the header will help prevent the header from splitting

due to improper adjustment of the closer or forced operation by the user.

MAINTENANCE: It is necessary to add lubrication to the grooves in the side to the ladder

from time to time. The grooves can be lubricated with a light grease, paraffin, bees wax or

petroleum jelly.

TROUBLE SHOOTING MODEL 26: If the ladder section is hard to move up and down along

its length, check the following:

Make sure the slide bars are operating in the grooves over the entire length of travel.

Make sure the ladder is lubricated (See Maintenance).

If the ladder seems to be binding, check the grooves for gouge marks, then check width

of ladder which should measure about 17-1/16” across the back.

Insure the tracks are sealed in the bottom of the gains and all of the ladder rods and

fasteners are tight.

The spring inside the spring drum is broken when the drum rotates without placing

tension on the cable. Never open up the spring drum as the spring may exit the drum

in a sudden and abrupt manner risking personal injury. Return drum to factory for repairs.

Insure the cables are riding straight and true on the drums. Also insure the drums are

not leaning to one side or wobbling. This may indicate that the bushings have come out of

the drums. (New bushings may be obtained from the factory).

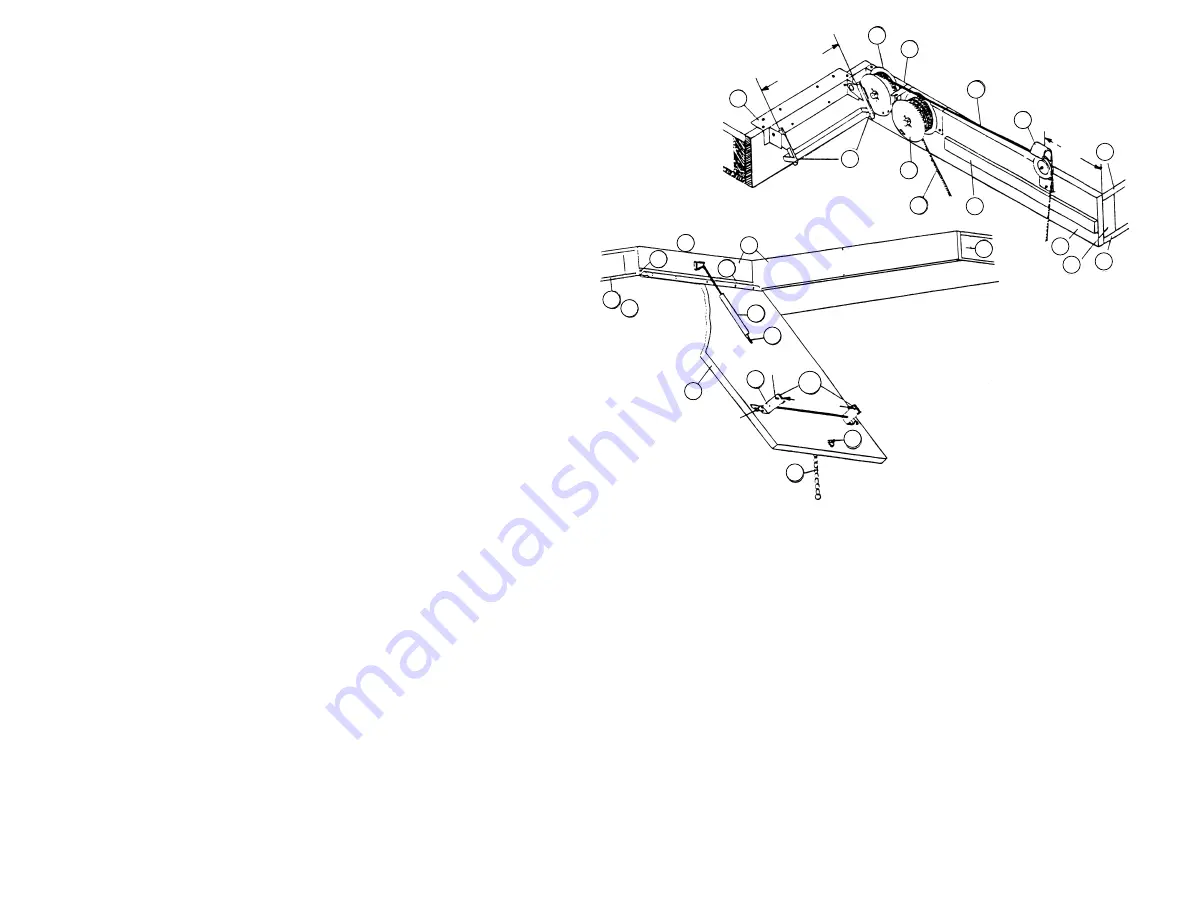

5

5A

7

6

8

12

25

11

9

24

20

21

22

23

22

21

28

26

23

24

15

10

29

30

16

10A

17

27

PIN

HOOK

D=16

5

/

8

WIDTH

D=16

5

/

8

FIG. 4.

FIG. 5.