BEST ACCESS SYSTEMS

Indianapolis, Indiana

For factory prepared doors only

Caution:

If you use hollow metal doors, decide whether the

doors are reinforced enough to support the lock. If door rein-

forcement is not adequate, consult the door manufacturer for

information on proper reinforcement.

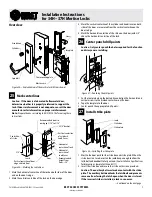

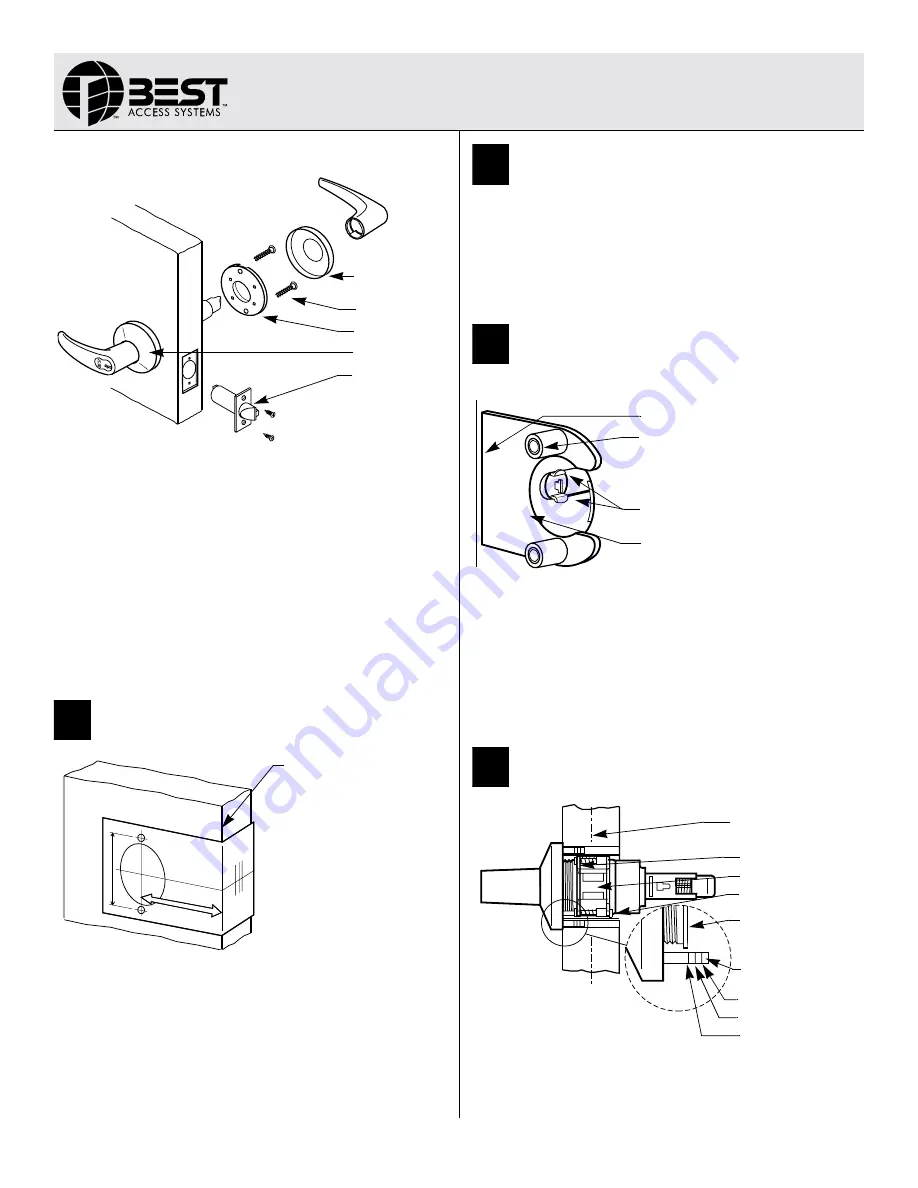

Simplified instructions

1 Install the latch so that the bevel on the latch bolt faces the strike.

2 Adjust the outside rose assembly so that the chassis is centered in

the door. Install the chassis from the outside of the door.

3 Install the inside liner, through-bolts, rose, lever and strike.

For field door preparation and detailed installation instructions, see the

following tasks.

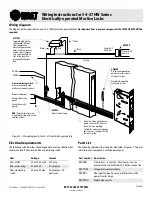

1

Position template

1 Fold the template and place in position on the high edge of the door

bevel (see Figure 38).

2 Mark the drill points.

Note:

Suggested height from floor to centerline of the lock is

40 5/16". If steel frames are used, the latch centerline must be in line

with the center of the strike preparation.

2

Bore two holes and install latch

1 Bore a 2 1/8" diameter hole from both sides of the door, to the center

of the door.

2 Drill a 1" diameter hole from the edge of the door that intersects the

2 1/8" hole.

3 Mortise the door edge for the latch face.

4 Install the latch and check the door swing. Latch tabs should project

into the 2 1/8" diameter hole. See Figure 39 in task 3.

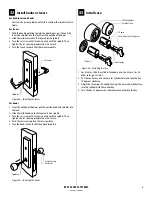

3

Install boring jig and drill two

5/16

”

diameter holes

1 Install the boring jig (KD303) onto the door and engage with latch

tabs. Make sure the front edge of the jig is parallel with the door

edge (see Figure 39).

2 Drill two 5/16" diameter holes halfway into the door.

3 Turn the boring jig over and repeat steps one and two from the

opposite side of the door.

Note:

Replace the boring jig after ten door preparations.

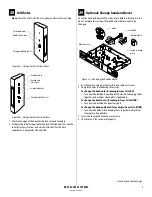

4

Adjust lockset to door thickness

■

Retract the rose locking pin and rotate the outside rose liner in or out

until the proper door thickness groove on the through bolt stud,

Figure 37

Figure 38

Inside rose

Inside liner

Latch

Through-bolts

Outside rose

TEMPLATE

High edge of door bevel

Figure 39

Figure 40

Door edge

5/16” diameter

Latch tabs

Boring jig

One-half door thickness

Hub face

Retractor

Pull pin to rotate rose

Hub face

2 1/4"

2"

1 3/4"

Door thickness grooves

—Continued

Installation Instructions

for 9K Cylindrical Locks

T56075/Rev – 1798029 ER-7991-1 Jan 2000

Summary of Contents for 34HW

Page 1: ......

Page 6: ...Contents vi W Series Service Manual...

Page 38: ...IDH Max Locks Functions and Parts 2 24 W Series Service Manual...

Page 54: ...Electrified Locks Functions and Parts 3 16 W Series Service Manual...

Page 140: ...Service and Maintenance for Cylindrical Locks 5 30 W Series Service Manual...

Page 158: ...Additional Service and Maintenance for IDH Max Locks 6 18 W Series Service Manual...

Page 162: ...Glossary A 4 W Series Service Manual...

Page 164: ...Installation Instructions B 2 W Series Service Manual...