BEST ACCESS SYSTEMS

a Division of Stanley Security Solutions, Inc.

1

The 45HM IDH Max® Mortise Lock provides the following

features in an integrated lock, eliminating the need to

install separate sensors in and around the door frame:

■

electrified locking mechanism

■

electronic token reader

■

integrated trim

■

door status detection

■

latchbolt status detection

■

ability to exit without triggering an alarm (RQE)

■

compatibility with varied access control panels/

reader interfaces.

Note:

For a list of compatible access control panels/

reader interfaces, contact your local BEST representative.

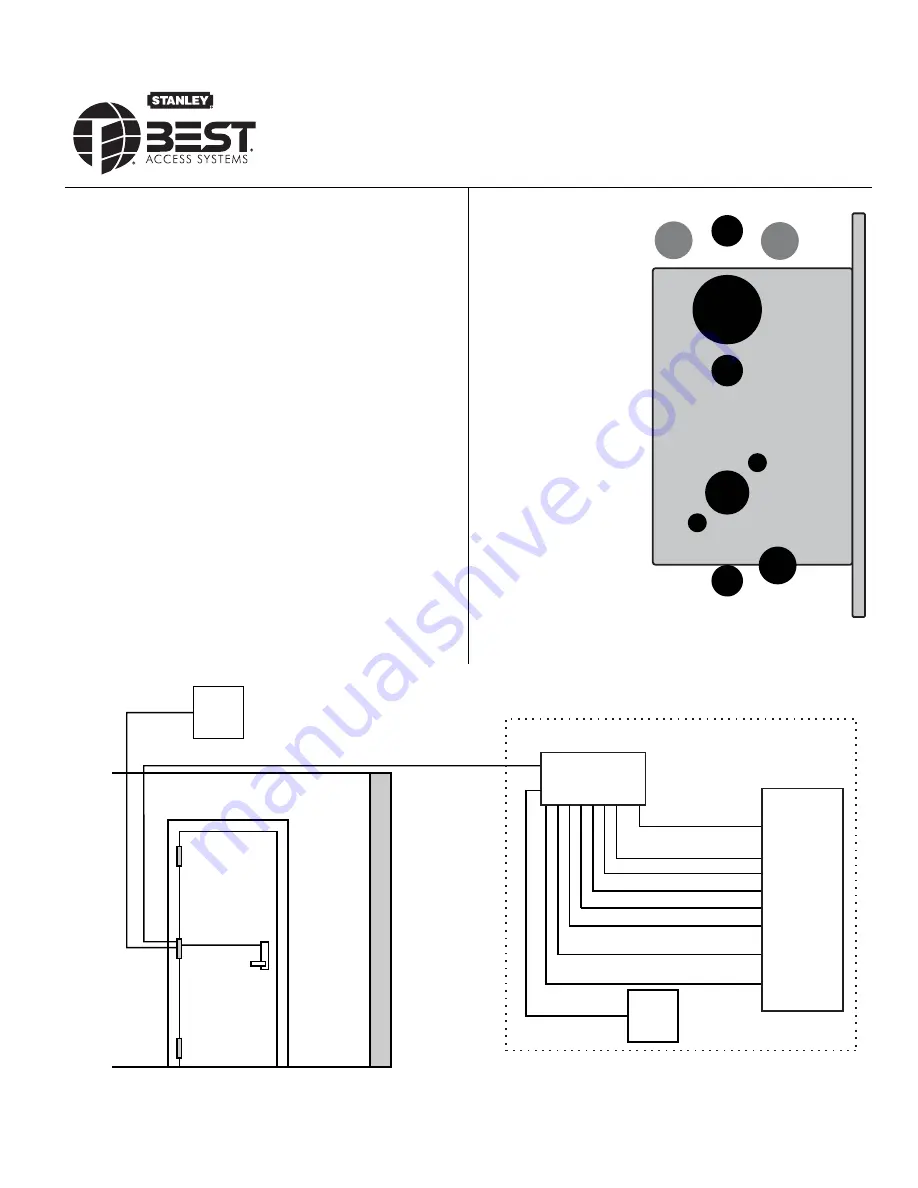

A panel interface module is provided with the lock. The

panel interface module receives token data and lock

sensor data from the lock through an RS-485 connection.

It translates this data into parallel signals, which it sends

to the access control panel/reader interface. The panel

interface module also translates control signals received

from the access control panel/reader interface and sends

them to the lock. The figure below shows the relationship

between the components in the IDH Max® system.

Installation Instructions for

45HM IDH Max® Mortise Locks

Power

supply

Lock

Wire

transfer

hinge

Field wire

harness

Power (2)

RS-485 Communication (2)

Communication tamper or

Latchbolt status (2)

Door & latchbolt status or

Door status (2)

RQE status (2)

Strike (2)

Token data (2)

Reader LED (2)

Sounder (2)

Card present (1)

Panel interface

module

Access

control

panel/

reader

interface

Power (2)

Power

supply

B

B

A

A

C

F

H

D

G

G

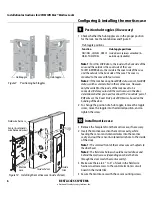

For hole sizes, see the

W28 Template (T81625)

Figure 1

Identifying holes to drill