It is important that the floor be level and square.

Before nailing the flooring, measure the floor

diagonally (corner to corner). Then measure

the opposite corners. These measurements will

be the same if the floor is square (187-1/2").

2.

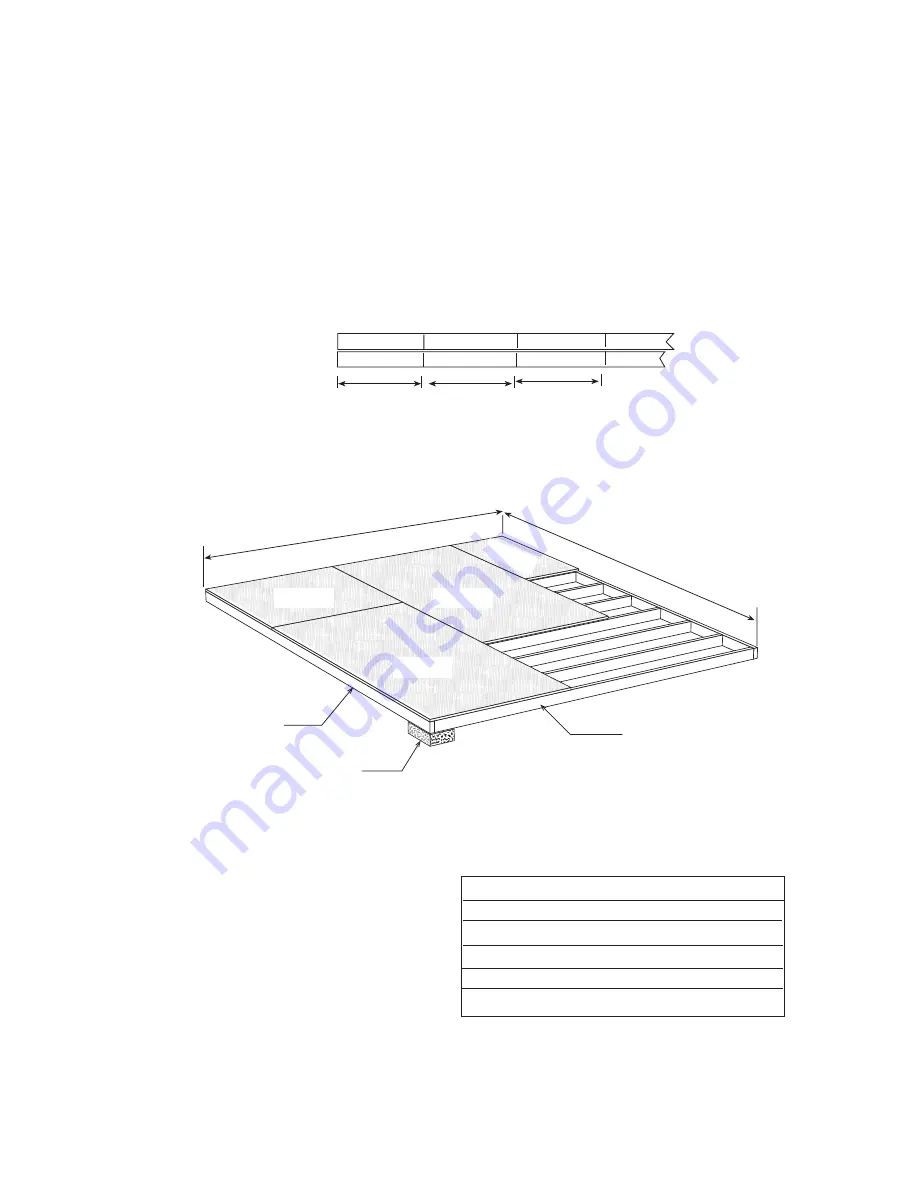

Cut (10) ten 2x4-10' floor joist to 9'-9". Treated lumber may be thicker than 1-1/2". Take this

into account when cutting the length of floor joists. Shorten joist measurements if necessary

to obtain 12'-0" building width.

1.

Treated lumber is not cut to exact length. Cut (2) two 2x4-12' boards to 12'-0".

Layout for 16" on center joist spacing. 'X' marks where floor joist will be placed.

Construction Details for Optional Floor System

Check local building codes in your area, the construction may have to change. For a concrete slab,

install sill sealer as a moisture barrier between the concrete and the wall plates. Foam sill sealer can

be purchased at home centers in rolls 3-1/2" or wider.

Material Description

10' x 12' Floor

2x4 Treated Headers

2 pcs.

12'

2x4 Treated Floor Joist

10 pcs.

10'

Flooring 5/8" 4x8

4 pcs. 4x8

8d Screw Floor Nails

1 lb.

8d

16d Galv. Box Nails

1 lb.

16d

If necessary use bricks, patio stones or similar material to level or provide additional support

to the floor. If your ground has low areas consider adding gravel and or 4x4 treated timbers

to rest the floor on. If you use 4x4 timbers you will need (3) three pieces 12' long.

3.

Install the floor joist, over the 'X' marks, between the 12' long joist headers. Use 16d galv.

deck nails.

!

!

Joist 9' - 9" Long

2x4-12' Joist Header

12' - 0" Floor Length

10' - 0" Floor Width

Leveling Blocks

4' x 8'

4' x 4'

4' x 8'

2' x 4'

X

X

X

X

X

X

16"

15-1/4"

Joist Header

X

X

16"