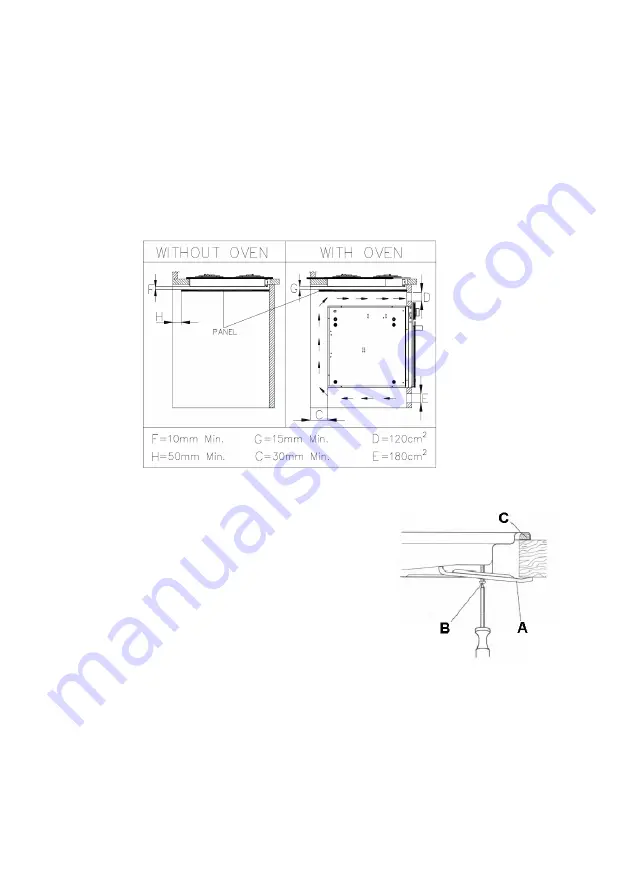

Isolation below (fig.7):

-

If the cooktop is installed without an oven below it, a separator panel must be placed between

the bottom of the cooktop and the housing below it, at a minimum distance of 10 mm.

-

If the cooktop is installed over an oven, place a separator panel at a minimum distance of 15mm and follow

the oven manufacturer's instructions, ensuring nonetheless sufficient aeration as specified in fig.7.

In any event, the electrical connection of the two appliances must be carried out

separately,

both for electrical safety and to facilitate removal.

It is advisable to use an oven equipped with an internal forced cooling system.

Fixing the cooktop (fig.8):

To fix the cooktop in the housing, proceed as follows:

-

Position the special gasket supplied [C] along the outer perimeter

of the worktop, following the diagram shown in fig.5, so that the

ends of the gasket meet exactly without overlapping

-

Position the cooktop into the worktop, taking care to ensure

it is placed exactly in the centre.

-

Fix the cooktop to the worktop using the special brackets

supplied [A], as shown in fig.8

Correct installation of the sealing gasket ensures complete protection against infiltration of liquids.

Installation area and removal of combustion fumes

The appliance must be installed and operated in suitable areas, and in compliance with current laws.

The installation technician must observe current laws governing ventilation and removal of

combustion fumes.

Please remind that the air required for combustion is 2m

3

/h per kW of power (gas) installed.

Fig.7

6

Summary of Contents for BH 31 IX

Page 1: ...BUILT IN COOKTOPS INSTRUCTIONS BOOKLET ...

Page 2: ......

Page 12: ...10 ...

Page 13: ... 90 396 73 23 2006 95 89 336 2004 108 93 68 89 109 1935 2004 11 ...

Page 14: ... 3 Y 90 1 2 3 4 5 6 7 8 9 3 3 12 ...

Page 15: ... 4 5 15 1 4 5 15 13 ...

Page 16: ... 4 5 1 2 140 x 350 1 6 1 10 200 240 160 200 160 R A 140 200 240 220 280 SR 60 TR 200 180 14 ...

Page 17: ...0 0 1 2 3 4 5 6 8 9 6 1 10 200 C 5 10 3 4 1 2 7 8 15 ...

Page 19: ... 10 7 8 5 8 2 3 100 2 200 2 9 UNI CIG 7129 7 9 17 ...

Page 21: ... N L J G30 G31 3 0 75 2 3 1 2 3 1 5 2 19 ...

Page 22: ... 20 ...

Page 28: ...26 ...

Page 29: ...27 ...

Page 30: ...28 ...

Page 31: ......

Page 32: ...H01A5121 ...