Installation Instructions for IDH Max 1300 Mortise Locks

BEST ACCESS SYSTEMS

A Division of Stanley Security Solutions, Inc

4

Preparing the door and door jamb

1

Mark centerlines

Note:

If the door is a fabricated hollow metal door,

determine whether it is properly reinforced to support

the lock. If door reinforcement is not adequate, consult

the door manufacturer for information on proper rein-

forcement. For dimensions for preparing metal doors,

see the

W13 Template—Installation Specifications for

34HM–35HM IDH Max Mortise Locks

.

1 On the door, measure and mark the height of the cen-

terline of the knob/lever from the floor (38

″

recom-

mended). On both sides of the door, on the door’s

edge, and on the door jamb, mark the horizontal cen-

terline of the lock 1 1/2

″

above the centerline of the

knob/lever.

Note:

If the door is a LH or RH door, mark the inside of

the door. If the door is a LHRB or RHRB door, mark the

outside of the door.

2 On the door’s edge and door jamb, mark the vertical

centerline of the lock.

3 Measure and mark the backset (2 3/4

″

standard) from

the vertical centerline on the door’s edge. On both

sides of the door, mark the vertical centerline of the

lock.

4 On the door jamb, mark the horizontal centerline of

the strike 3/8

″

above the horizontal centerline of the

lock.

2

Position template and mark drill points

1 Cut

the

W15 Template—Installation Template for

34HM–35HM

IDH Max Mortise Locks

along the dashed

lines and align the horizontal and vertical arrows with

the marked centerlines on the door.

2 Tape the template to the door.

3 Center punch the necessary drill points. Refer to the

instructions on the template.

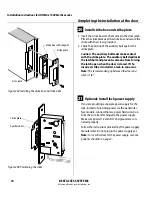

Figure 1

Marking the centerlines

Door jamb

Door

Vert. centerline

of lock

Horz. centerline

of lock

Horz. centerline

of knob/lever

(38

″

from floor

recommended)

Vert. centerline

of door’s edge

Horz. centerline

of strike

Vert. centerline

of strike

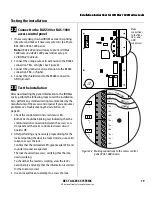

Figure 2

Positioning the template

Installation template

Horizontal centerline

of lock

Horizontal centerline

of knob/lever

Vertical centerline

of lock