3

70

M

O

TO

R C

H

EC

k

S AN

d

ASS

EM

B

LY

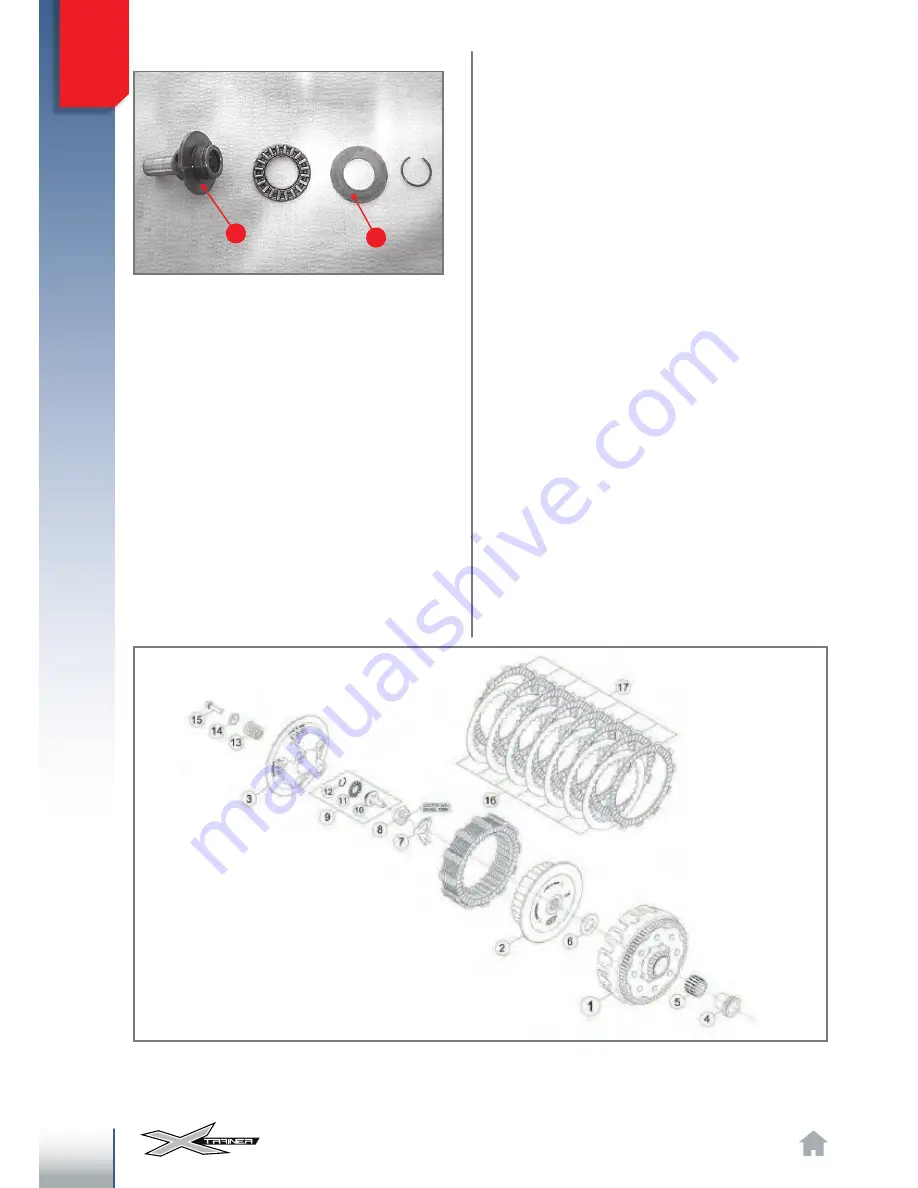

Thrust bearing device.

3.8.7

Thrust bearing device

check

Check the state of use of the thrust bearing and

the surfaces upon which it rests. In order to check

the thrusting bearing, just see if it slides. When

the device is assembled, simulate rotation of the

front centre Bearing

A

respect to the rear one

B

.

Be careful for presence of traces of meshing or

wear on the sliding surfaces.

3.8.8

Clutch unit assembly

After having lubricated the end of the main trans-

mission shaft, insert the internal centre bearing

4

to which the roller bearing must be coupled

5

.

Insert the clutch case

1

followed by the 21.7x38x3

washer

6

, upon which the clutch drum will rest

2

. Put on the safety washer

7

and after having

applied medium strength threadlocker, couple

the lock nut

8

. Slightly rotate the kickstart idler

gear and the clutch case to facilitate inserting the

clutch case.

A

B

ExplODED vIEW OF clUTcH UNIT.

1) complete case 2) clutch drum; 3) clutch cap; 4) Internal centre bearing; 5) Roller bearing 26x30x22; 6) Washer; 7) Safety washer;

8) Nut M18x1,5; 9) Overall thrust bearing; 10) clutch body rod coupling; 11) Thrust bearing; 12) circlip RB14; 13) clutch spring; 14)

clutch spring retainer; 15) Screw M6x25; 16) Driven discs; 17) Driving discs.

Summary of Contents for X Trainer 300 2T 2015

Page 1: ...CODE 036440030 000...

Page 19: ...2 17 Engine disassembly Remove the four collar nuts 9 9 Extract the cylinder and base gaskets...

Page 116: ...114 NOTES...

Page 117: ......