27

PROBLEM

CAUSE

No operation.

Electric system failure.

Jack can go up, but it cannot go down.

Descent solenoid valve failure.

Electric system failure.

Jack goes down very slowly.

Descent control valve does not operate normally.

Motor operates normally, but jack cannot be lifted.

Descent solenoid valve stopped in opening position.

Oil may be missing.

Motor operates normally, but lift goes up very slowly.

Descent solenoid valve partially open.

Suction filter partially clogged.

Pump damaged.

Stated capacity cannot be lifted.

Maximum pressure valve not calibrated correctly.

Pump damaged.

Lift cannot go down.

(EMERGENCY DESCENT).

Descent valve does not open (N.10-11). Power failure.

Call customer service.

Electrical fault.

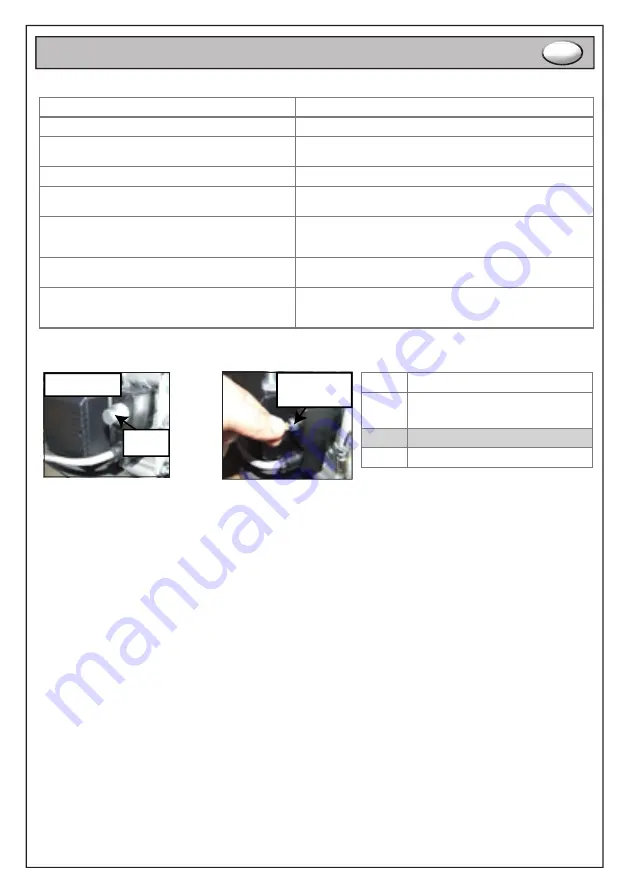

Item

Description

C

KNURLED BRASS PIN TO BE

UNSCREWED ANTICLOCKWISE.

B

KNURLED NUT OF SOLENOID VALVE

A

DESCENT SOLENOID VALVE

.

A

B

C

Figures 10-11

12. SCRAPPING INFORMATION

- If the jack is no longer to be used, it should be made unserviceable by removing the power connection plug.

- If the jack is to be scrapped, it should be considered as special waste and thus disposed of in accordance with current

national laws.

13. PERIODIC TESTS AND REGISTER

A General Visual Inspection should be performed on a DAILY basis to check the following:

• The general state of the jack and whether any parts are damaged or missing;

• The legibility of the tags attached to the jack, in order to replace any illegible tags;

• Leaks in the hydraulic circuit. A slight dampening effect is admitted, provided that no drops form.

DECLARATION OF CONFORMITY

We hereby declare, assuming full responsibility, that the described product complies with all the relevant

provisions of Machine Directive 2006/42/EC and amendments thereto.

The Technical Brochure is available at:

BETA UTENSILI S.P.A.

Via A. Volta 18

20845 Sovico (MB)

ITALY

ISTRUZIONI PER L’USO

I

OPERATION MANUAL AND INSTRUCTIONS

EN

Summary of Contents for 3050/K

Page 114: ...114 ...

Page 115: ...115 ...