3

113

E

N

G

IN

E ASS

E

M

B

LY AN

D CO

NTRO

LS

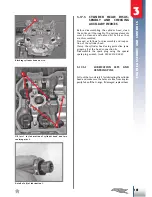

Extraction of valve stem seals from valve stems.

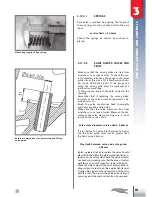

Checking flatness of cylinder head.

3.17.4.3

VALVE STEM SEAL AND LO-

WER STOP WASHER

Should there be excessive oil consumption or

a white-like exhaust smoke which cannot be

blamed on the oil-scraper rings on the piston,

replace the valve stem seals

1

, intended to pre

-

vent excess oil leakage.

It is recommended to replace them every time

the cylinder head is overhauled.

In order to replace them, use needle-nose pliers

to pull them out, being careful not to nick the

valve guide.

Once the valve stem seal is extracted, the lower

cup can be pulled out

2

.

3.17.5 CYLINDER HEAD: CHE-

CKING CYLINDER HEAD

BODY

Check the flatness between the head and cylin

-

der coupling surfaces.

This can be done using a rectified block and a

thickness gauge by positioning the block accor

-

ding to the directions shown in the figure.

The service limit is:

cylinder head flatness service limit: 0.05mm

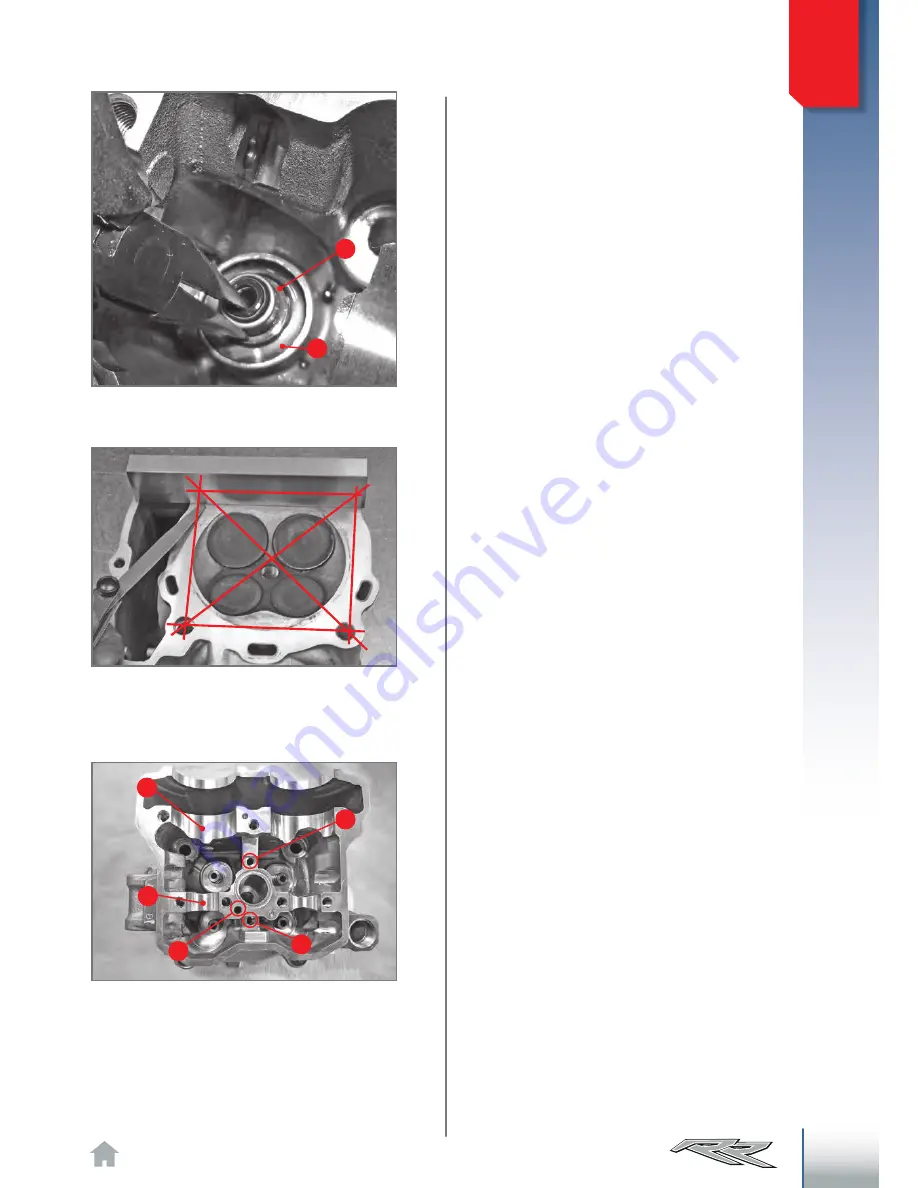

Check that the state of use of the sliding zones

A

with the camshafts and

B

of the camshaft

support bearing housing are free of scratches

or signs of meshing.

Clean the oil passages for lubricating the cylin

-

der head by blowing compressed air into the

holes

C

,

D

and

E

.

1

C

B

A

E

D

2