3

55

E

N

G

IN

E ASS

E

M

B

LY AN

D CO

NTRO

LS

C

10Nm

B

A

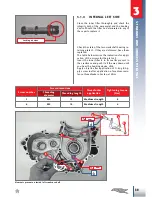

EXPLODED VIEW OF STOPPING DEVICE

25) Lever;

26) Spring;

27) Spacer;

28) Washer 6x20x1;

29) Screw M6x20.

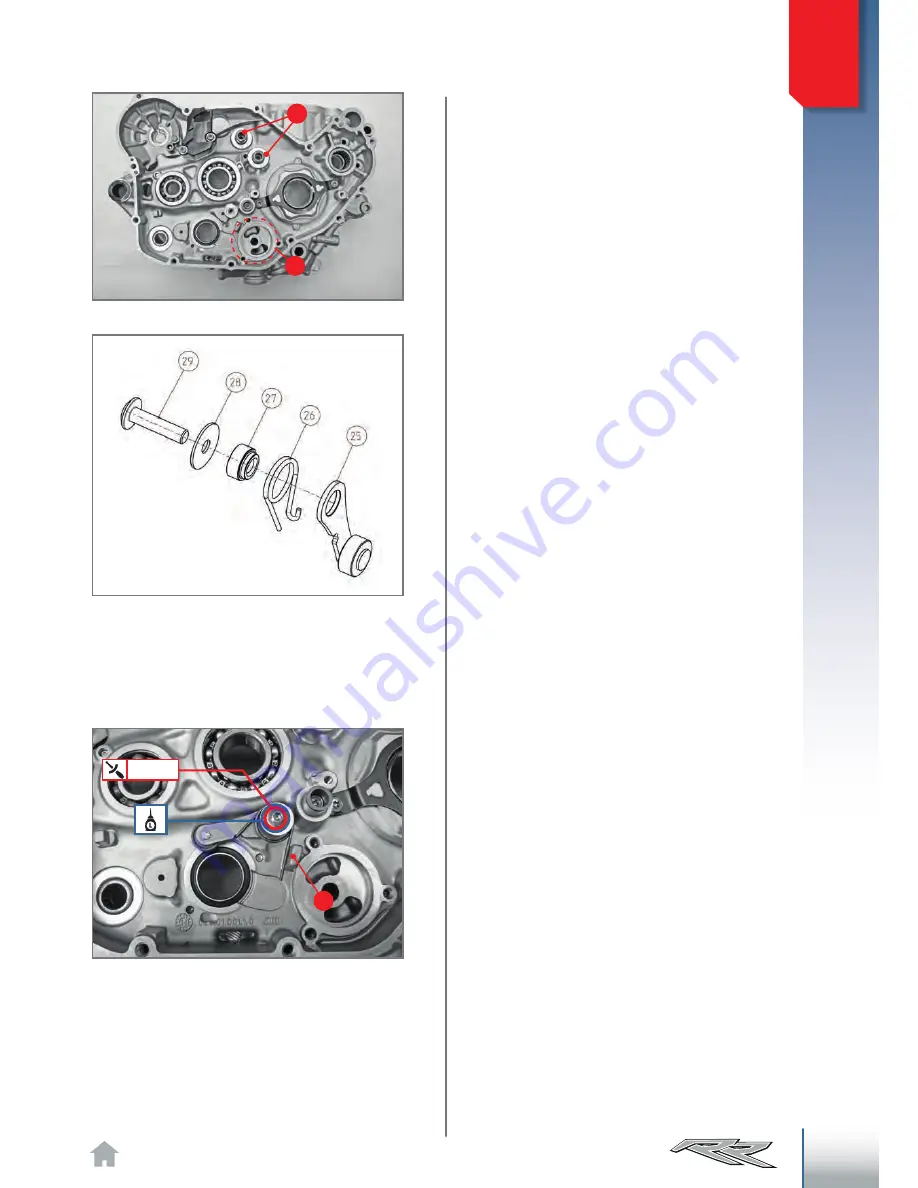

Stopping device coupled with the crankcase half.

The crankcase half will definitely need to be re

-

placed when:

•

the oil pump crankcase

A

shows deep

scratches or meshing signs;

•

the two pins

B

for the idler wheel and tor

-

que limiter show traces of abnormal wear

or meshing.

Keeping the tightener on the lever

25

facing to

-

wards the crankcase half, apply the spacer

27

onto it, by inserting the smaller diameter seg

-

ment in the lever. Apply the spring

26

so that

the hook inserts into the groove present on the

lever

25

and then apply the washer

28

and the

screw

29

M6x20 whose threading must be spre

-

ad with medium strength threadlocker.

Apply the entire device on the crankcase half so

that the straight segment of the spring rests on

the stop

C

. Tighten the screw at 10Nm.