63

ASSEMBLY

betamotor.com

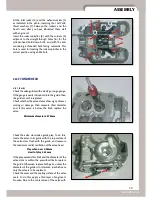

Fit the decompressor weight (4) and the relative

spring (5). The spring must be preloaded by half a

turn when fitted. Then check that the decompressor

mass returns automatically to its initial position af-

ter being displaced. If this does not happen, replace

the spring.

N.B. Oil the contact areas between the decompressor

mass and the other parts in the camshaft assembly.

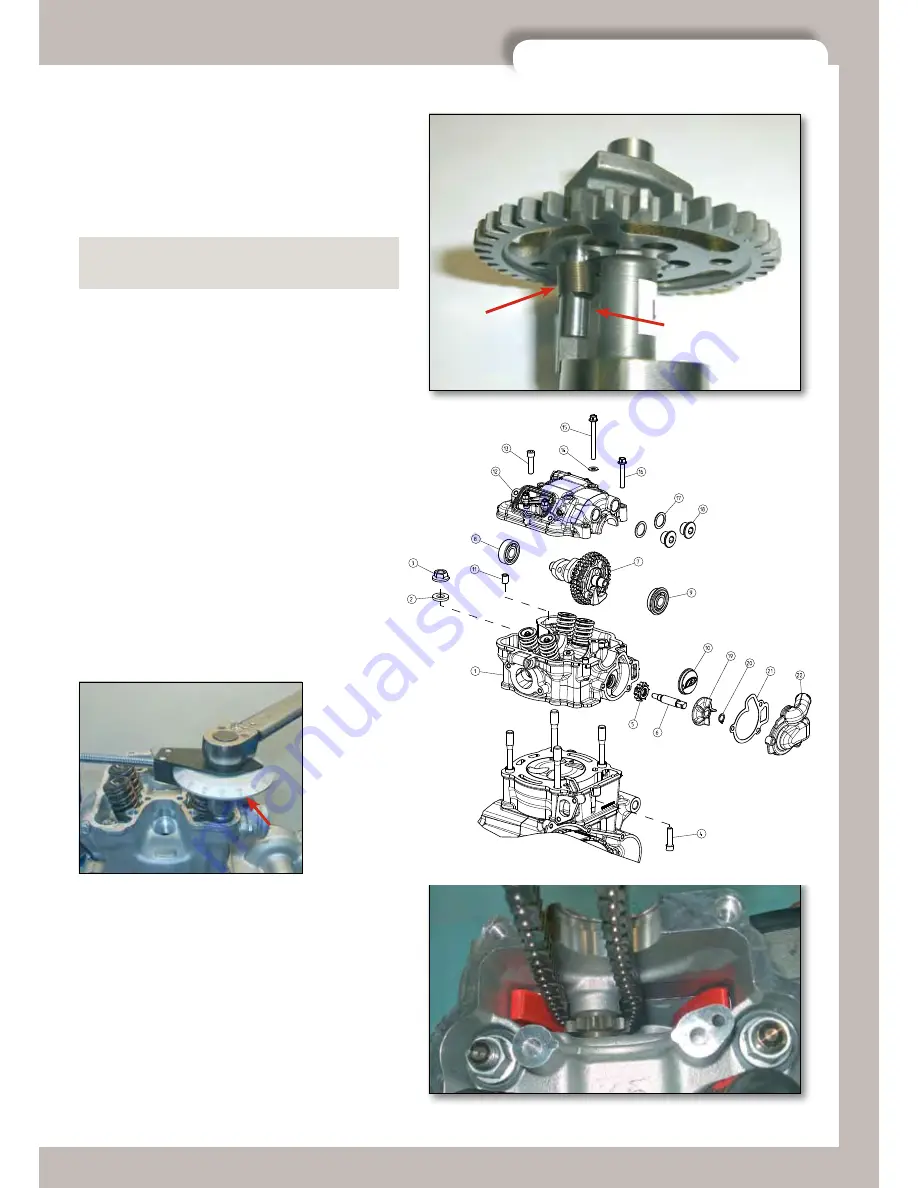

4.17.2 Fitting the valvegear

Fit the head (1) onto the cylinder, tapping it several

times in the area of the dowels in order to facili-

tate seating. Fit the washers (2) and screw the nuts

(3) onto the studs, tightening them in diagonal se-

quence, starting with the studs in proximity to the

dowels, after applying molycote grease. Tighten in

diagonal sequence to 30 Nm. Then, using a pro-

tractor disc (A), continue tightening the nuts on the

studs, forcing them through a rotation of 70°. If such

a tool is not available, tighten the nuts to 50 Nm.

Tighten the M6x25 bolt (4) to 10 Nm.

Fit the water pump drive sprocket (5) into its hous-

ing in the timing case, with the smaller-diameter

face towards the inside, and then the water pump

shaft (6) after you have lubricated it with oil.

Check the diameter of the water pump shaft in the

area where it makes contact with the seals. Signs of

wear may be visible in this area. If the diameter is

less than the limit value, replace the shaft to avoid

sealing problems.

Minimum diameter 9.7mm

4

5

A