16

1. CLEANING THE SQUEEGEE HOSE

Check the squeegee hose for blockage if the suction is insufficient and at peri-

odic intervals. To clean the hose:

A. Remove the hose end from the squeegee hose adapter.

B. Remove the other end of the hose from the recovery tank.

C. Wash the inside of the hose with clear water, spraying from the end that con-

nects to the tank.

D. Reinstall the hose.

WARNING: Do not wash the hose that goes from the vacuum unit to

the recovery tank. This will damage the vacuum motor!

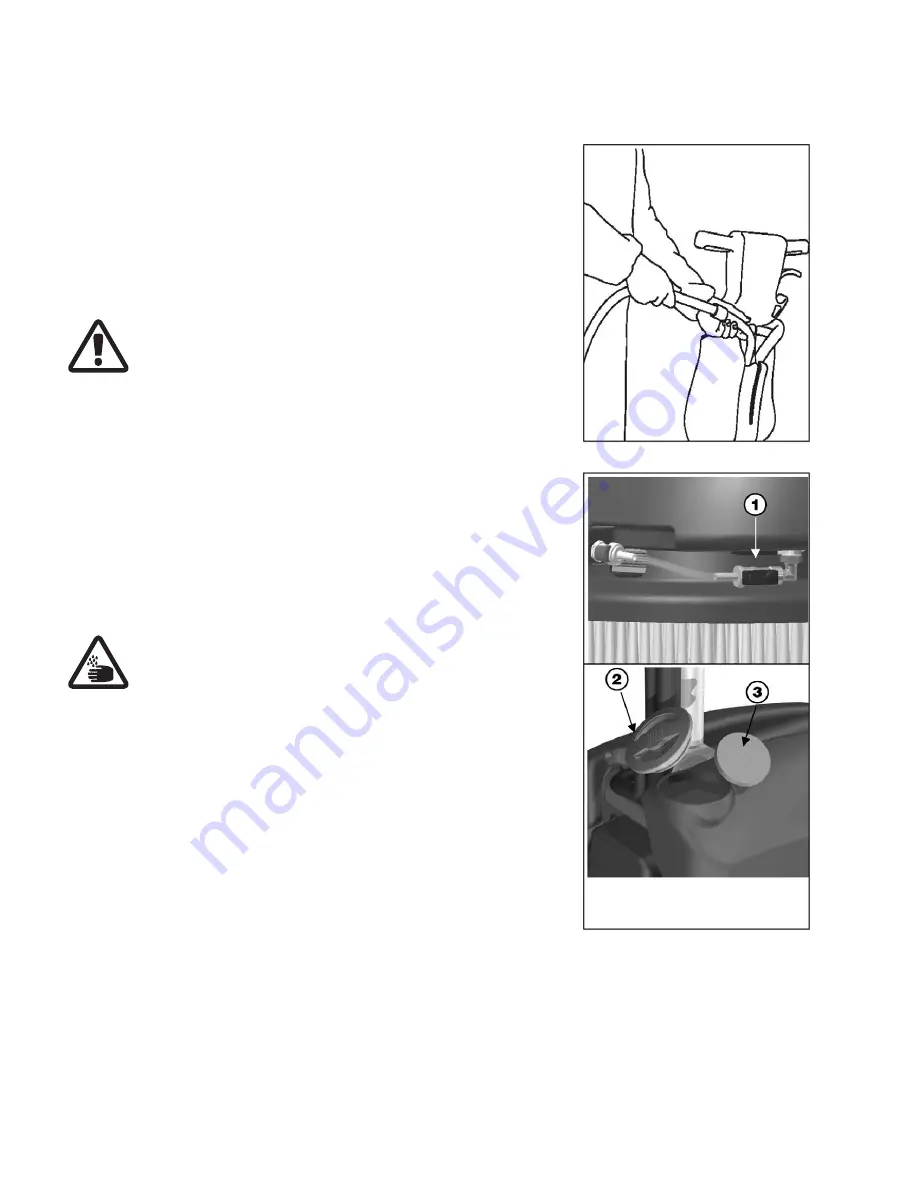

2. CLEANING THE SOLUTION TANK AND FILTER

1. Disconnect the quick connection at the front of the machine (

1

).

2. Remove the solution tank from the machine.

3. Unscrew the solution cap (

2

).

4. Remove the screen filter (

3

) and rinse with clean water.

5. Rinse the inside of the tank with clean water.

6. Install the tank back on the machine.

WARNING: Always wear gloves to protect yourself from contact

with hazardous chemicals.

SCHEDULED MAINTENANCE

Summary of Contents for Genie B

Page 19: ...19 ...

Page 22: ...22 SQUEEGEE SYSTEM PARTS DIAGRAM 5 18 7 1 8 16 15 11 2 3 6 4 17 17 2 12 9 10 11 12 11 14 13 ...

Page 24: ...24 SQUEEGEE YOKE PARTS DIAGRAM 13 2 5 1 10 7 3 11 14 8 6 12 4 9 ...

Page 32: ...32 ELECTRIC SYSTEM PARTS DIAGRAM 4 7 2 1 6 3 5 ...

Page 38: ...38 ...

Page 39: ...39 ...