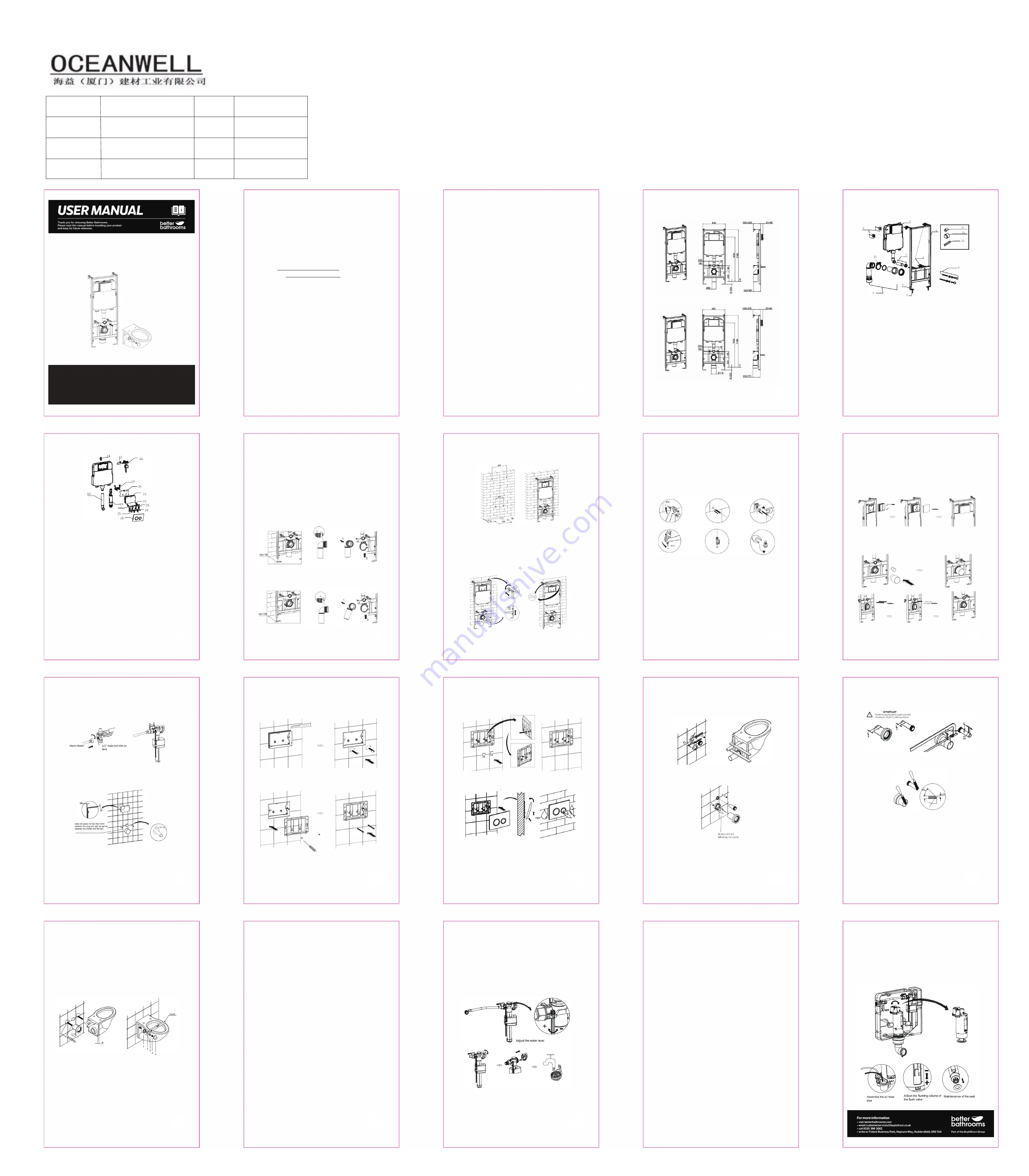

Wall Frame and Cistern

BeBa_25877

x

For installation with Flush Plates - BeBa_26132 / BeBa_25874 /

BeBa_25876 (sold separately)

x

Toilet pan sold separately

Please note: Image is for illustrative purposes only and may differ slightly to the

actual product

x

Multi-person assembly

x

Tools required

x

We always recommend using professional

tradespeople to install your product

V2 8.7.21

Ϯ

Congratulations on your purchase

And welcome to our growing gang of savvy shoppers

We're on a mission to bring you extraordinary bathroom products, for less. From modern

to traditional style ceramics, plus the gorgeous fixtures, fittings and furniture to match. So,

you can fall in love with your space every single day.

As one of the UK's largest independent bathroom stores, we've received countless

awards; including the National Business Awards UK, the Digital Entrepreneur Awards and

being placed on The Sunday Times Fast Track 100.

We hope your new product goes above and beyond your expectations. However, should

any problems occur, please:

x

log in to your account and contact our customer services team via your self-serve

portal

–

betterbathrooms.com/CustomerAccount/Login

x

contact us via betterbathrooms.com/content/contact-us

Important information

x

Please read these instructions thoroughly and retain for future reference.

x

Manufactured to BS EN14055 WC and urinal cisterns.

x

All installation work must be carried out to comply with the Water Bylaw

Regulations.

x

The installation should be designed to allow access for maintenance.

ϯ

Contents

x

Dimensions

4

x

Parts

5-6

x

Tools required

6

x

Installation

R

Fitting Pan connector

7

R

Adjusting Frame Height

8

R

Securing the Frame

9

R

Fitting Protective Covers

10

R

Water Connection

11

R

Installation once wall is constructed

12-15

R

Connecting and Hanging the Toilet

16

x

Troubleshooting

17

x

Maintenance

18-19

ϰ

Dimensions

ϱ

Parts

1. Square inlet fixing plate

–

Pre-fitted

2. Tank

3. Frame

4. Wall fixing brackets and screws

5. Flush pipe and bung

6. Pan connector and seals

7. Adjustable foot

8. Adjustable floor foot fixing screw and plug

9. Toilet fixings

10. Flush pipe protector, use during installation

11.

Pan connector protector, use during installation

12. Fixing bar sleeves, use during installation 1

13. Pan connector clip

14. Stop Valve

–

Pre-fitted

ϲ

15. Inlet flexi-pipe

–

Pre-fitted

16. Inlet valve

17. Flush plate bracket

18. Flush pipe vertical

19. Syphon

20. Flush rod locating plate

21. Flush plate protective cover

22. Flush plate fixing rods

23. Flush plate housing

24. Flush plate housing/rod clips

25. Flush rods

26. Flush plate

Tools required

x

Screwdriver

x

Spanner

x

Pencil

x

Drill

x

Sprit Level

x

10mm Drill Bit

x

Hacksaw

ϳ

Installation

Please note:

Whenever possible and when safe to do so, it is recommended to carry out

leak tests during the installation process

Fitting Pan Connector

If using a straight connector through the wall, you can position as required.

Each option below will give you the minimum dimension from the wall to the front of the

fixing foot.

Please note:

The desired location should be checked before drilling, that no pipes or

wires can be damaged

Option 1: Pan connector to be installed into the floor

Position the connector into the frame clip in the position shown below left, located in the

rear recess, then close the clip.

Option 2: Pan connector to be installed to the side

Position the connector into the frame clip in the position shown below left, located in the

front recess, then close the clip.

ϴ

Below show the fixing width dimensions for the wall and floor screws, and the distance

from the centre of the pan connector.

Adjusting Frame Height

Once the pan connector is in place, the height of the frame can be adjusted as required

along with the depth of the frame from the wall.

1. To do this loosen the nuts and bolts in the fixing brackets and adjust as required.

2. Check the frame is level and then tighten the nuts and bolts.

3. Once the frame is set to the required height and depth, mark the drill holes on the

wall, and on the floor.

Now you’re ready to secure the frame.

ϵ

Securing the Frame

1. Drill the holes using a 10mm drill bit; it is recommended to place tape over the drill

mark if you are drilling into tiles to prevent any slippage.

2. Once drilled, if fixing to a solid wall and floor, push the wall plug into the hole.

3. Secure the wall bracket to the wall and then position the frame into the required

location.

4. Tighten the frame to the wall bracket and tighten the nut and bolt.

5. Secure the foot into position using the screws provided.

ϭϬ

Fitting Protective Covers

Before building the wall, and tiling around the frame, the protective covers need to be

fitted to the flush plate housing, flush pipe and pan connector and the fixing bars fixed into

place.

1. Fit the flush plate fixing bracket (as below), then fit the flush plate fitting box.

Please note:

The Flush Plate is sold separately

2. Push on the flush pipe and pan connector covers.

3. Screw the threaded bars into the frame, as below, ensuring these are in the correct

hole to match the holes in the toilet, then push on the sleeves.

ϭϭ

Water Connection

1. Make the connection between the water supply and the cistern tank, using a

suitable sealing method as shown below.

Please note:

The cistern has its own built in stop valve

2.

Once water is connected you’re ready to build the partition wall. Use the guidance

below and construct as required then tile as required.

ϭϮ

Installation once wall is constructed

1. Once the wall is constructed and tiled to the required depth, cut the flush plate box

to the finished wall surface.

2. Insert the fixing rods into the holes within the frame flush box and twist to secure.

3. Secure the flush plate bracket to the fixing rods and secure using the screws

provided.

4. Push the flush rods into the housing as shown below.

ϭϯ

5. Once the rods are fully inserted, secure into position using the clips shown below,

then push the rods to ensure free movement is achieved.

6. Attach the flush plate and click into position.

ϭϰ

7. Remove the pan connector and flush pipe protective covers.

8. Push the straight pan connector, flush pipe and remaining parts into the holes in

the frame.

9. Mark a line at the finished wall surface.

10. Remove from the frame and connect them to the flush hole and waste spigot on the

rear of the toilet pan (Apply a small amount of washing up liquid to assist).

ϭϱ

11. Once fully connected, mark the measurements and cut as shown below.

ϭϮ͘

Prepare the flush pipe and pan connector ends removing any rough edges and

create a small chamfer.

ϭϲ

Connecting and Hanging the Toilet

1. Push the pan connector into the frame then push the flush pipe into the toilet

2. Remove the threaded bar sleeves.

3. Unscrew the threaded bars, so they extend by dimension A depth of the toilet wall

+ 25mm.

Please note:

You will require two people for this section of the installation

4. Lift the toilet pan onto the threaded bars.

5. Finally, check that the toilet is level, connect the fixings in the order shown below

and tighten until the toilet pan is secured.

Please note:

Once installation is completed a full commissioning of the product should be

carried out to check the installation is safe and stable, check for leaks and check function

ϭϳ

Troubleshooting

Cistern tank not filling at all or to the required level

1. Check the water supply has been turned back on and is reaching the cistern.

2. Adjust the fill level on the cistern as required.

3. The filter on the inlet valve could be blocked.

4. If none of these resolve the issue replace the inlet valve.

Flush volume into the pan, not sufficient

1. Adjust the flush volume level on the syphon.

2. Check that the syphon is opening correctly.

3. Check that the tubes are connected to the correct inlet on the flush plate.

4. If none of these resolve the issue replace the syphon.

Water running into the pan continually after flushing

1. Establish if the water level in the cistern is reaching the overflow on the syphon, if it

does, adjust the inlet valve.

2. If this continues, replace the inlet valve.

3. If the water level does not reach the overflow on the syphon, remove the top

section of the syphon and check the washer for damage.

4. If damaged replace.

ϭϴ

Maintenance

The maintenance measures below require you to gain access to the internals of the

cistern tank, and for the water supply to be turned off.

x

Once you have gained access, turn the adjustment screw in the required direction

to adjust the tank fill volume.

x

If you need to replace the inlet valve, disconnect the water supply pipe and remove

the retaining nut, which holds the inlet valve to the tank and pull the inlet valve from

the tank.

x

To clear the filter, unscrew the filter section from the inlet valve as shown and run

under warm water using a brush to clean away any blockage.

ϭϵ

x

It is recommended to remove the pneumatic tubes from the syphon to carry out

maintenance.

x

To do this, pull each tube from the inlet on the top of the syphon, do not allow these

to drop back into the tank.

x

To remove the syphon, you will only need to remove the top section, which requires

you to twist and lift.

x

To adjust the flush volume, move the slider as shown below.

x

To remove the washer, turn the syphon upside down and the washer from the

housing.

+&#

236J701-E71-01B

2021.12.08

175X260mm

20

100克双胶

料号

材质

日期

页数

表单编号

尺寸

版本

1.0

版本

1.0