Form Title:

Document #:

INSTALLATION AND MAINTENANCE MANUAL

MM-AD001

(Form: DEF-006A-1)

Revision:

4

Document Title:

Date:

Air Commander™ Air Distributor

Oct. 23, 2017

Page:

5 of 8

Betts Industries Inc.

▪

814·723·1250

▪

1800 Pennsylvania Ave. West

▪

Warren, PA 16365

▪

www.BettsInd.com

Print Date: 10/23/2017

This form is considered uncontrolled 24 hrs. after print date.

5.0

Installation

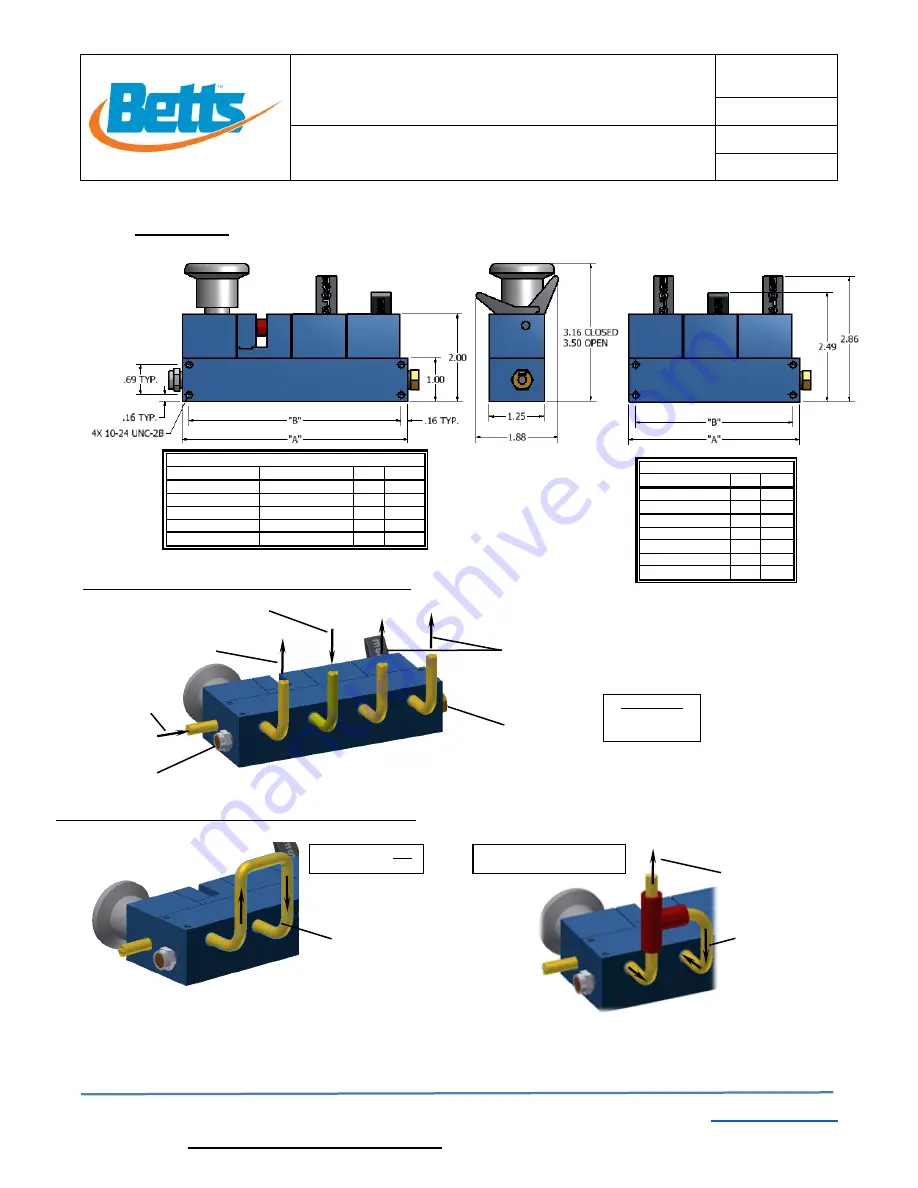

OUT TO NON-SEQUENTIAL

VAPOR VALVES

JUMPER LINE USED TO

BYPASS AIR TO TOGGLES

PART NUMBERS

Pull and Hold

Push/Pull

“A”

“B”

AD14PH1ALFS

AD14PP1ALFS

3.91

3.59

AD14PH2ALFS

AD14PP2ALFS

5.16

4.84

AD14PH3ALFS

AD14PP3ALFS

6.41

6.09

AD14PH4ALFS

AD14PP4ALFS

7.66

7.34

AD14PH5ALFS

AD14PP5ALFS

8.91

8.59

Master Control Sequential Plumbing

Layout

Master Control Non-Sequential Plumbing Layout

–

(SAME AS SEQUENTIAL BUT WITH JUMPER LINE AS SHOWN BELOW)

NON-SEQUENTIAL VAPOR

VALVES PLUMBED INTO SYSTEM

PART NUMBERS

Toggles Only

“A” “B”

AD14TO1ALFS

1.41 1.09

AD14TO2ALFS

2.66 2.34

AD14TO3ALFS

3.91 3.59

AD14TO4ALFS

5.16 4.84

AD14TO5ALFS

6.41 6.09

AD14TO6ALFS

7.66 7.34

AD14TO7ALFS

8.91 8.59

OR

FITTING NOTE

:

ALL FITTING HOLES

ARE 1/8-27 NPT

VAPOR VALVES NOT

PLUMBED INTO SYSTEM

JUMPER LINE USED TO

BYPASS AIR TO TOGGLES

AIR OUT FROM MASTER

CONTROL TO VAPOR VALVES

RETURN AIR FROM VAPOR VALVES TO

PRESSURE INDICATOR SLIDE AND FEED

COMPARTMENT TOGGLES.

AIR SUPPLY IN

EXHAUST PORT

(DO NOT PLUG)

AIR OUT TO COMPARTMENT EMERGENCY

VALVES WHEN TOGGLE SELECTED

FUSIBLE PLUG